Nippon Yakin Kogyo Co., Ltd

Nippon Yakin Kogyo NASNW22 Corrosion Resistant Alloys

Manufacturer: Nippon Yakin Kogyo Co., Ltd

Model : NASNW22

| Chemical Composition | 57Ni 21Cr 14Mo 3W 4Fe | ||

| Product shape |  Coil Coil |  Sheet Sheet |  Plate Plate |

| Workability | High-temperature strength is higher than Type 304, requiring care when hot working. Cold workability similar to standard austenitic stainless steels like Type 304, 316, etc. When performing cold work, consider the high strength of the material. | ||

| Weldability | Ordinary welding methods can be used with stainless steels. Matching welding consumables should be used. You do not need to perform post-weld heat treatment. | ||

| Heat Treatment | Solution annealing at 1150–1170°C, followed by quenching in water or rapid cooling. | ||

| Pickling | Nitric acid and hydrofluoric acid used in pickling.Descaling is more challenging compared to Type 304, so it’s essential to proactively implement stronger techniques such as alkaline immersion before pickling or shot blasting to improve efficiency.Alkaline immersion before pickling and shot blasting are effective. | ||

| Applications | Chemical plants, Pharmaceutical plants, Environment-related equipment, Heat exchangers. | ||

| Chemical Composition | 57Ni 21Cr 14Mo 3W 4Fe | ||

Grade/Standard

| Nippon Yakin Grade | JIS G 4902 | ASTM B575 | DIN 17744/17750 |

|---|---|---|---|

| NASNW22 | NW6022 | UNS N06022 | 2.4602 |

Chemical Composition

| C | Si | Mn | P | S | Ni | Cr | Mo | Fe | Co | W | V | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Specification (NW6022) | ≤0.015 | ≤0.08 | ≤0.50 | ≤0.020 | ≤0.020 | Bal. | 20.00-22.50 | 12.50-14.50 | 2.00-6.00 | ≤2.50 | 2.50-3.50 | ≤0.35 |

| Specification (UNS N06022) | ≤0.015 | ≤0.08 | ≤0.50 | ≤0.02 | ≤0.02 | Bal. | 20.00-22.50 | 12.50-14.50 | 2.00-6.00 | ≤2.5 | 2.5-3.5 | ≤0.35 |

Physical Properties

| Density [g/cm³] | 8.70 |

|---|---|

| Specific heat [J/kg•K] | 414 |

| Electrical resistivity [μΩ•cm] | 114.0 |

| Thermal conductivity [W/m•K] | 10.0 |

| Average coefficient of thermal expansion [10⁻⁶/°C] | 20–100°C 11.5 |

| 20–200°C 12.7 | |

| 20–300°C 13.0 | |

| 20–400°C 13.5 | |

| 20–500°C 13.8 | |

| Young’s modulus [MPa] | 20.4 × 10⁴ |

| Magnetism | None |

| Melting range [°C] | 1325–1372 |

Mechanical Properties

| 0.2% proof stress [MPa] | Tensile strength [MPa] | Elongation [%] | Hardness [HRBW] | |

|---|---|---|---|---|

| Specification (NW6022) | ≥310 | ≥690 | ≥45 | — |

| Specification (UNS N06022) | ≥310 | ≥690 | ≥45 | — |

| Hot-rolled plate (12mm) | 367 | 744 | 73 | 88 |

| Cold-rolled sheet (3mm) | 383 | 782 | 57 | 86 |

Corrosion Resistance

Pitting Corrosion Resistance

| Alloy | ASTM G48 Method A | ASTM G48 Method C Critical pitting corrosion temperature CPT (°C) |

|---|---|---|

| NAS185N | ○ | 70 |

| NAS254N | ○ | 80 |

| NASNW22 | ○ | >103 |

Test conditions: ASTM G48 Method A (○: No pitting corrosion, X: Pitting corrosion)

– Test solution: 6% FeCl₃

– Test temperature: 22°C, 50°C (Recommended temperature in this test)

– Test time: 72h

Crevice Corrosion Resistance

| Alloy | ASTM G48 Method D Critical crevice corrosion temperature CCT (°C) |

|---|---|

| NAS185N | 40 |

| NAS254N | 45 |

| NASNW22 | >103 |

Test conditions: ASTM G48 Method D

– Test solution: 6% FeCl₃ + 1% HCl

– Test time: 72h

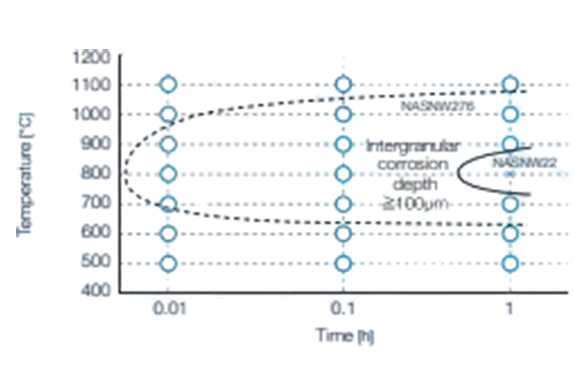

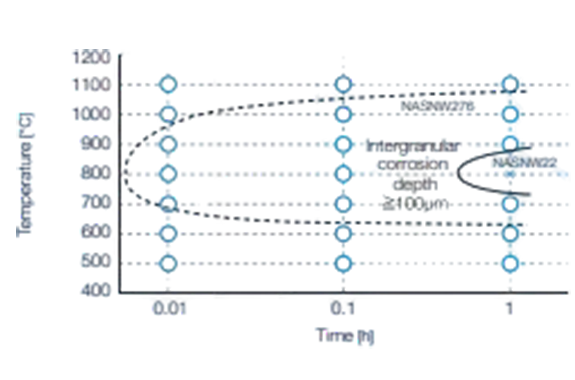

Intergranular Corrosion Resistance

Test conditions: ASTM G28 Method A

Test time: 24h

Boiling 50% H₂SO₄ – Fe (SO₄) solution

Stress Corrosion Cracking Resistance

| Alloy | MgCl₂ concentration (boiling point °C in brackets) | 45% (153°C) | 38% (142°C) | 35% (136°C) | 30% (123°C) | 25% (119°C) | 20% (110°C) |

|---|---|---|---|---|---|---|---|

| NAS185N | x | x | x | x | ○ | ○ | |

| NAS254N | ○ | ○ | ○ | ○ | ○ | ○ | |

| NASNW22 | ○ | ○ | ○ | ○ | ○ | ○ |

Test conditions:

– Immersion in boiling MgCl₂ solution

– Test time: 300h

○: No stress corrosion cracking, x: Stress corrosion cracking

They use a U-bend test specimen.

Acid Resistance

Corrosion rate in sulfuric acid at 80°C (mm/y)

| Alloy | 5% | 10% | 20% | 40% | 60% | 80% |

|---|---|---|---|---|---|---|

| NAS185N | 0.02 | 0.04 | 1.32 | 2.89 | 3.02 | 4.78 |

| NAS254N | 0.02 | 0.05 | 0.06 | 2.11 | 2.76 | 7.76 |

| NASNW22 | 0.01 | 0.02 | 0.04 | 0.07 | 0.34 | — |

Test time: 24h

Corrosion rate in hydrochloric acid at 80°C (mm/y)

| Alloy | 0.1% | 1% | 2% | 3% | 5% |

|---|---|---|---|---|---|

| NAS185N | 0.01 | 0.02 | 4.29 | 7.21 | — |

| NAS254N | 0.01 | 0.02 | 0.02 | 2.96 | 7.74 |

| NASNW22 | 0.02 | 0.03 | 0.04 | — | — |

Test time: 24h

Reference

| Alloy | JIS | UNS No. | Chemical Composition |

|---|---|---|---|

| NAS185N | SUS312L | S31254 | 20Cr-18Ni-6Mo-0.8Cu-0.2N |

| NAS254N | SUS836L | S32603 | 23Cr-25Ni-5.5Mo-0.2N |

| NASNW22 | NW6022 | N06022 | 57Ni-21Cr-14Mo-3W-4Fe |

Workability

Because NASNW22 has much higher high-temperature strength than Type 304, operators must take extra care when hot working. NASNW22’s cold workability is similar to standard austenitic stainless steels like Type 304 and Type 316. However, operators must account for its high-strength properties during cold working.

Weldability

In welding, it is possible to apply ordinary welding methods in the same manner as with stainless steels. Matching composition welding consumables should be used. Post-weld heat treatment is not required.

Heat Treatment

Solution annealing of NASNW22 is normally performed at the temperature range from 1150 to 1170°C followed by being quenched in water or rapidly cooled by other means.

Pickling

A mixture of nitric acid and fluoric acid is used in pickling. However, because descaling is somewhat difficult in comparison with Type 304, alkali immersion before acid pickling, and if possible, shot blasting are extremely effective.

Applications

Chemical plants, Pharmaceutical plants, Environment-related equipment, Heat exchangers.

Related Products

-

Nippon Yakin Kogyo NAS8R10 Neutron Absorbing Stainless Steel

-

Nippon Yakin Kogyo NAS800 Heat Resistant Alloys

-

Nippon Yakin Kogyo NASPB SoftMagnetic Alloys

-

Nippon Yakin Kogyo NAS355N Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NASH880 Corrosion Resistant Alloys

-

Nippon Yakin Kogyo NAS255 Corrosion Resistant Alloys