Nissan Tanaka

NISSAN TANAKA AU150B-H12 Ⅱ Pressure Regulator For Other Applications

Manufacturer: Nissan Tanaka

Models: AU150B-H12 Ⅱ

You can continuously and stably supply a flow rate of 150L/min.

Features

- A high-capacity heater enables continuous and stable supply, even at a high flow rate of 150L/min.

- Ideal for supplying multiple welding machines or for welding with wind-resistant torches.

- Equipped with a flowmeter, allowing for flow rate control.

- You can use it for a wide range of applications, including agriculture, in addition to welding purposes..

Specifications

| Product Name | AU150B-H12 II | |

|---|---|---|

| Type of Gas Used | CO2 | |

| Pressure Gauge [MPa] | Inlet Side | 25 |

| Outlet Side | 1 | |

| Operating Pressure Range [MPa] | Inlet Side | 12 |

| Outlet Side | 0.6 | |

| Inlet/Outlet Shape | Inlet Side | W22-14 Right Mounting Nut |

| Outlet Side | M12×1 Right Male | |

| Accessory | Bag Nut + 08.5 Hose End | |

| Flow Meter Specifications | Method | OUT style |

| Range | 40~150L/min(nor) | |

| Set Pressure (MPa) | 0.6 | |

| Operating Temperature Range [°C] | -5~40 | |

| Material (Body) | C3771 | |

| Exhaust valve | Available | |

| Construction | With heater | |

| Electrical capacity | AC100V, 900W | |

| Heater power cord length [m] | 3 | |

| Weight [kg] | 3.1 | |

※ You cannot use it with siphon-type containers.

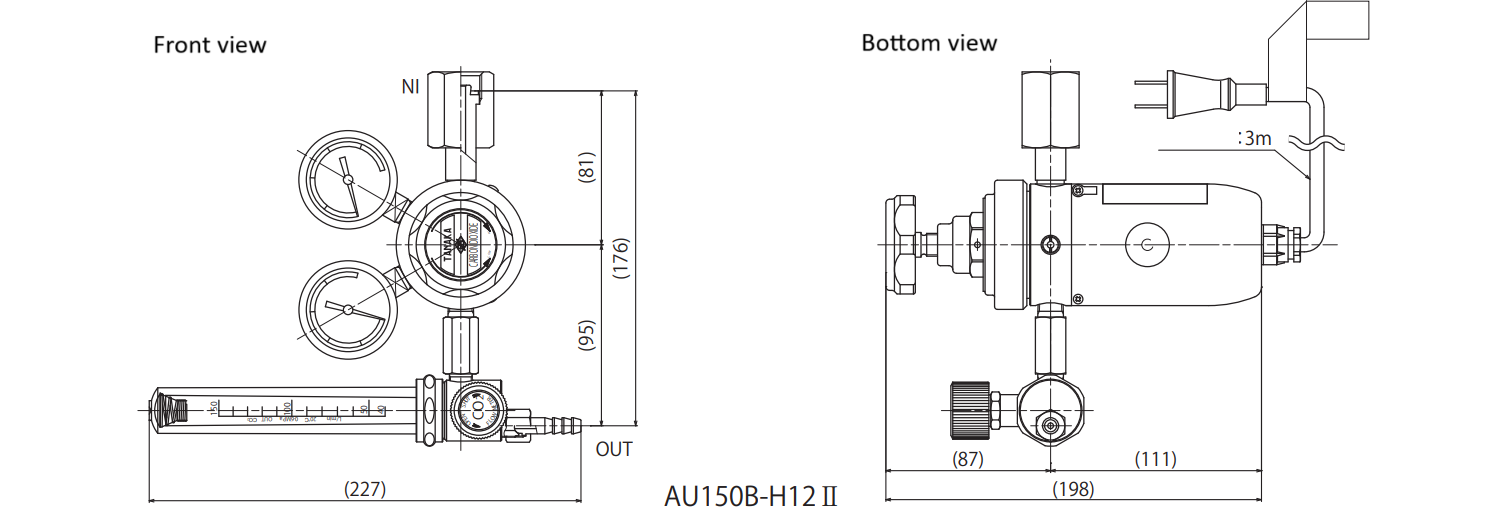

External view

Welding-related products

Heater-less CO2 Pressure Regulator

- No power supply has been required, making it energy-efficient.

- Equipped with fins with a large contact surface area to efficiently absorb temperature from the atmosphere.

- Despite its compact size, it can handle high flow rates for your use.

※Siphon-type containers cannot use it.

Ultra-high-speed Automatic Shading Surface

- We have achieved ultra-fast shading with a response speed of 1/12000 second at a low price.

- You can adapt it to different types of welding and current usage by adjusting the brightness from #9 to #13.

- You can adjust the sensitivity to the arc light.

- The headband has been improved, enhancing the comfort of wearing.

Anti-spatter Agent For Torches

- By simply immersing the nozzle for 1 second, you can significantly extend the nozzle’s lifespan.

- It protects the nozzle, contact tip, and other components from spatter.

- It ensures a smooth gas supply and a reliable arc.

PROBAN® Welding Apron & Cooling Vest

- PROBAN® processing has been a flame-resistant treatment developed by the English company Rhodia.

- It is a flame-resistant treatment for 100% cotton.

- Its excellent flame resistance is recognized in workwear for European steel companies.

- Through the introduction of foreign technology and our unique processing, we offer high-quality and highly safe flame-resistant products.

- We also have cooling vests available.

- They deliver cool air into the vest through a heat exchanger, providing a comfortable working environment!

Gas Mixer