Nissan Tanaka

NISSAN TANAKA FMM II Laser Cutting Machine

Manufacturer: NISSAN TANAKA

Model: FMM II

Features

Carbon Monoxide System

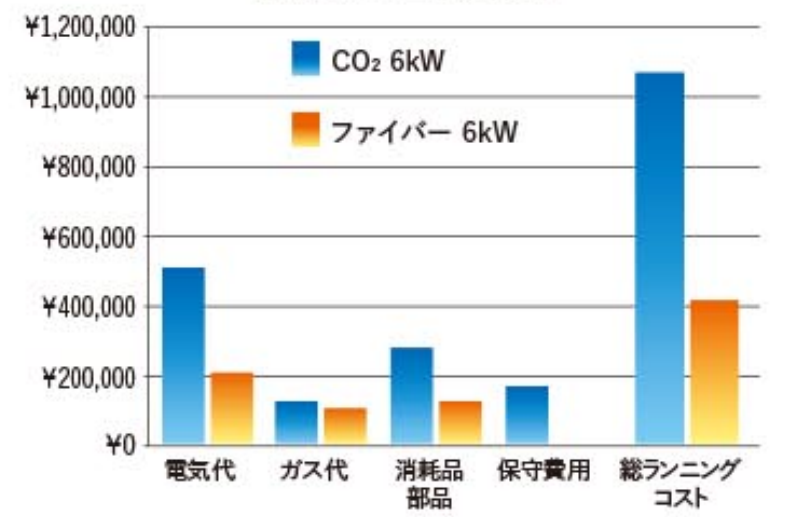

By optimizing the CO2 laser welding machine and introducing a “high-speed joint” technique (patent pending), it’s possible to increase productivity dramatically. With this technology, up to 63% of the laser system’s operational time can be reduced. Example: 6kW CO2 laser → 6kW fiber laser system comparison

“High Thickness, High Speed” “No Bevel” Revolutionary Welding Technology

A welding technique that doesn’t require beveling has been realized for 10mm to 20mm thick plates using a unique laser beam. This fiber laser allows for a significant reduction in welding bead width. By reducing it to a minimum of 6mm, the TANAKA laser system, which eliminates the need for traditional grooving, can achieve high-speed welding. This leads to a substantial reduction in welding time with the TANAKA laser system for thick plates.

Stable Operation in Outdoor Environments

The stability of the laser hand-held welding machine in outdoor operations is significantly improved. By introducing a wind resistance feature, it’s possible to perform stable welding even in environments with strong gusts.

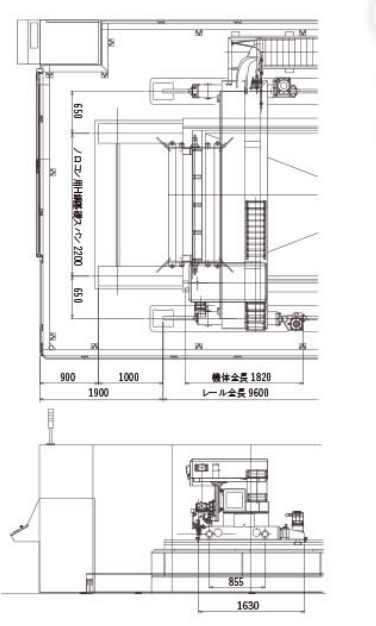

Specifications

| 2030 | 2060 | 2530 | 2560 | 3030 | 3060 | |

| Module Size (mm) | 3500 | 4000 | 4500 | |||

| Maximum Load Capacity per Module (mm) | 2100 X 3100 | 2100 X 6100 | 2600 X 3100 | 2600 X 6100 | 3100 X 3100 | 3100 X 6100 |

| Rail Weight | 50kg/m rail | |||||

| TI 6000 (6kW) | TI 12000 (12kW) | |

|---|---|---|

| Product | Aluminum Casting | Aluminum Casting |

| Steel Material SS400 (Grey Cast) | Approx. 19mm | Approx. 28mm |

| Steel Material (Black Cast) | Approx. 32mm | Approx. 38mm |

| Cutting Speed | 1〜24,000 mm/min |

| Feed Rate | 48000mm/min |

| Manual Feed Rate | 24000 mm/min |

| Tool Head Upward Speed | 20000 mm/min |

| Tool Head Downward Speed | 15000 mm/min |

| Origin Return Speed | 24000 mm/min |