Nissan Tanaka

NISSAN TANAKA FMR II Laser Cutting Machine

Manufacturer: NISSAN TANAKA

Model: FMR II

Features

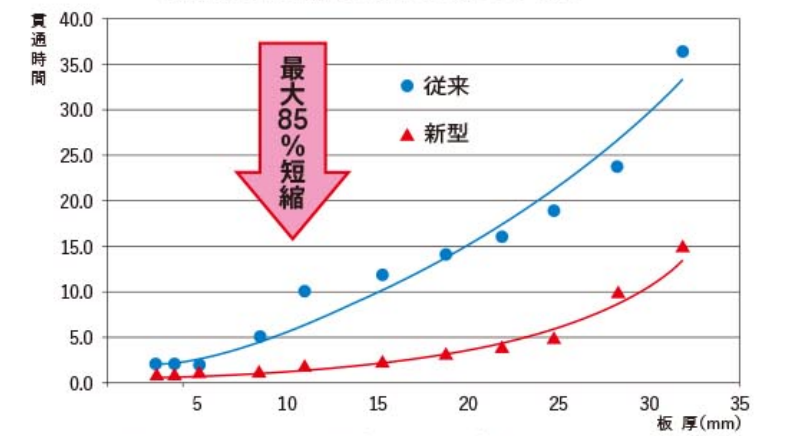

Small Hole and Precision Cutting Possible

Due to the low occurrence of burning, it is possible to perform precision cutting such as cutting holes less than half the plate thickness, sharp angles, and narrow slits.

In the case of CO2 lasers, it is common to perform pre-burning before cutting painted steel plates.

In the case of fiber lasers, relatively good cutting quality can be achieved without pre-burning.

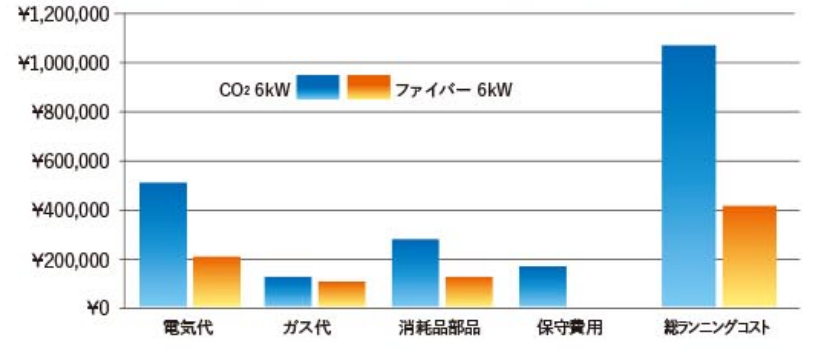

Consumables and regular replacement parts such as “laser gas,” “optical system mirrors (internal/external),” “discharge tubes,” and “turbo blowers” are not required.

With power consumption factored in, it is possible to reduce running costs by approximately 63%.

There is no regular maintenance such as mirror cleaning, and there is no power reduction due to optical system degradation.

The oscillator’s startup time is short, leading to a significant reduction in machine downtime. ※6kW C0: Awaiting comparison between CO2 laser and 6kW fiber laser.

Specifications

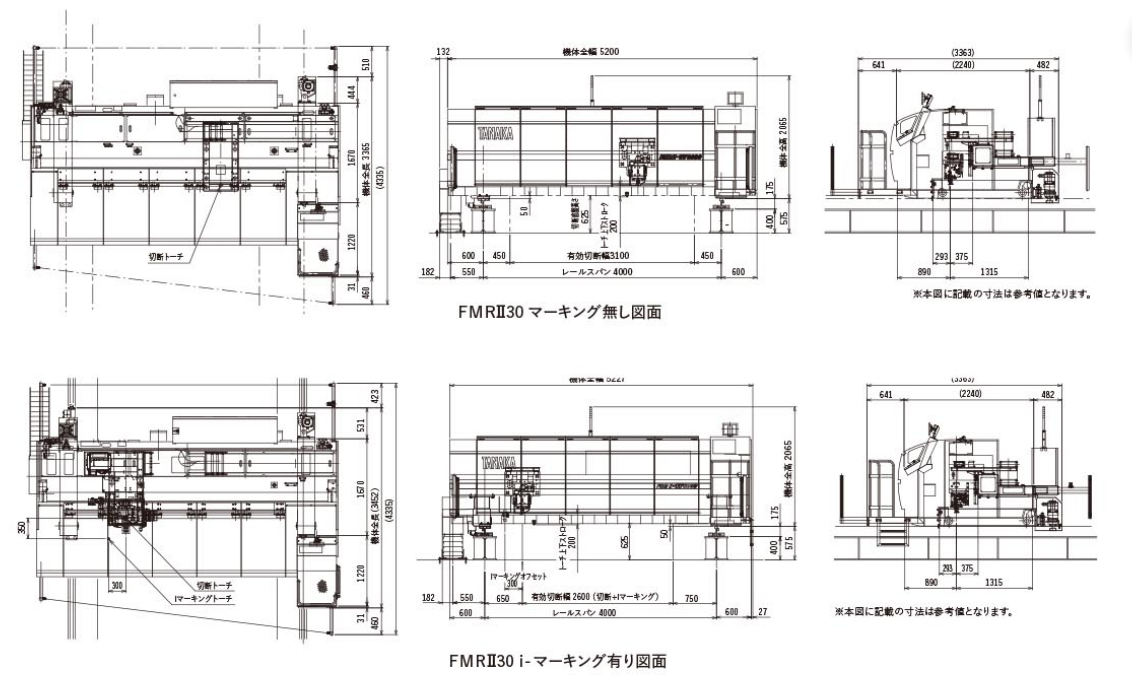

| Specification Size | 25 | 30 | 35 | 40 | 45 | 50 | 55 | |||||||

| Effective Cutting Width (mm) | 2600 | 3100 | 3600 | 4100 | 4600 | 5100 | 5600 | |||||||

| Rail Span (mm) | 3500 | 3,800 | 4,000 | 4,300 | 4,500 | 4,800 | 5,000 | 5300 | 5,500 | 5,800 | 6,000 | 6,500 | 6,500 | 7,000 |

| Standard Overall Width (mm) | 4700 | 5200 | 5700 | 6200 | 6700 | 7400 | 7900 | |||||||

| Standard Weight (kg) | 3800 | 3900 | 4000 | 4200 | 4400 | 4600 | 4800 | |||||||

| Material | Assist Gas | TI 6000 (6kW) | TI 12000 (12kW) |

|---|---|---|---|

| Mild steel (CW cutting) | ~ 19mm | ~ 19mm | ~ 28mm |

| Mild steel (Pulse cutting) | ~ 32mm | ~ 32mm | ~ 38mm |

| Stainless steel SUS304 | ~ 20mm | ~ 20mm | ~ 30mm |

| Aluminum A5052 | ~ 20mm | ~ 20mm | ~ 30mm |

| Function | Speed (mm/min) |

|---|---|

| Processing speed adjustment | 1 to 24,000mm/min |

| Rapid traverse rate | 36,000mm/min |

| Super rapid traverse (Option) | 60,000mm/min |

| Home return speed | 24,000mm/min |

| Manual rapid feed rate | 12,000mm/min |

| Processing head rising speed | 20,000mm/min |

| Processing head descending speed | 15,000mm/min |

| i-Marking speed | 24,000mm/min |

| Arc-on speed | 24,000mm/min |

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka

Related Products

-

NISSAN TANAKA PMG-M0050/M0100 Gate-Type Picking Machine

-

NISSAN TANAKA AU25B-H12 II Pressure Regulator

-

NISSAN TANAKA WELDSONIC Ultrasonic Inspection Unit For Weld Zones

-

NISSAN TANAKA COMET(CML Series) Industrial Pressure Regulator

-

NISSAN TANAKA Weld Monitoring Camera

-

NISSAN TANAKA TF2000, TF4000, TF6000 Remote Monitoring