Nissan Tanaka

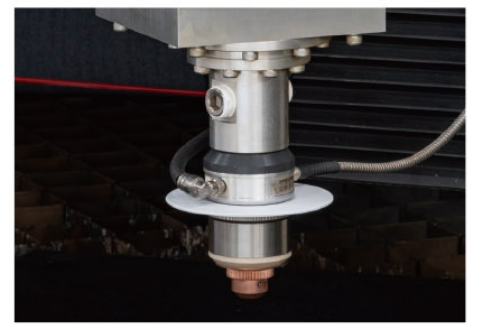

NISSAN TANAKA FMR III Laser Cutting Machine

Manufacturer: NISSAN TANAKA

Model: FMR III

Product introduction

The FMR III series is the newest line of racing helmets.

Designed for the highest level of professional racing, this series provides a superior fit and comfort, along with excellent ventilation and visibility.

Furthermore, it incorporates a shell structure that enhances safety against impacts from any direction.

[Enhanced visibility] RS-CW Lens (Range-Spread-CW)

The FMR III racing helmet series has been updated with the “RS-CW lens” to enhance visibility.

The special coating applied to the lens surface significantly improves visibility in a wide range of conditions, including during night races or in environments where visibility is generally poor.

Additionally, the unique lens curve ensures a wide field of vision without the distortion that is common with conventional lenses

High-definition visibility

CW (Clarity-Width) Lens Technology enhances visibility.

The helmet visor does not fog up easily due to its breathability, ensuring clear vision at all times.

The lens is resistant to scratches and can withstand the harsh environments of road and racing conditions.

It provides clear visibility in various weather conditions, including rain, fog, and bright sunlight. (Anti-reflective and hydrophobic coating included)

Cooling System

Adopted a new cooling system that improves air intake efficiency.

The newly designed system can reduce CO2 levels within the helmet, making it more comfortable to wear.

Air taken in through the front and top vents is circulated efficiently, and a large exhaust port in the back expels hot air

Aerodynamic Design

Stability and Streamlining

The shape of the helmet, including the spoiler and the air ducts, is designed aerodynamically to reduce drag and improve stability at high speeds. The air ducts also help reduce lift that can occur at high speeds, ensuring a stable ride.

Efficiency of Ventilation and Heat Escape

The X/Y duct system efficiently channels hot air out. The X duct contributes to an updraft, facilitating the discharge of hot air from the top. The Y duct allows hot air to escape from the rear, reducing heat accumulation inside the helmet, thus improving comfort.

Material Technology

The helmet is manufactured using high-strength materials that are 15% to 19% lighter than conventional fiberglass materials, contributing to fatigue reduction during long races. The helmet also incorporates a complex laminate construction that offers high resistance to impacts. This technology is combined with FANUC and in-mold helmet molding techniques to ensure a high level of safety and lightness

Maintenance and Support

By simplifying the structure around the head cushion and cheek pads, it has become easier to remove and install them, which significantly improves maintenance efficiency.

The surface is treated with a dirt-resistant coating, making cleaning easier.

The internal pads can be adjusted with a fine precision fit, and the helmet can be comfortably worn for a long time due to its excellent fit.

The fastening system is designed to be easily used even by those who are not accustomed to wearing helmets.

Additionally, a special tool is not required for pad adjustment.

A helmet equipped with a communication system can be easily connected to a 20kW radio (OD8) communication terminal, allowing for clear communication

Specifications

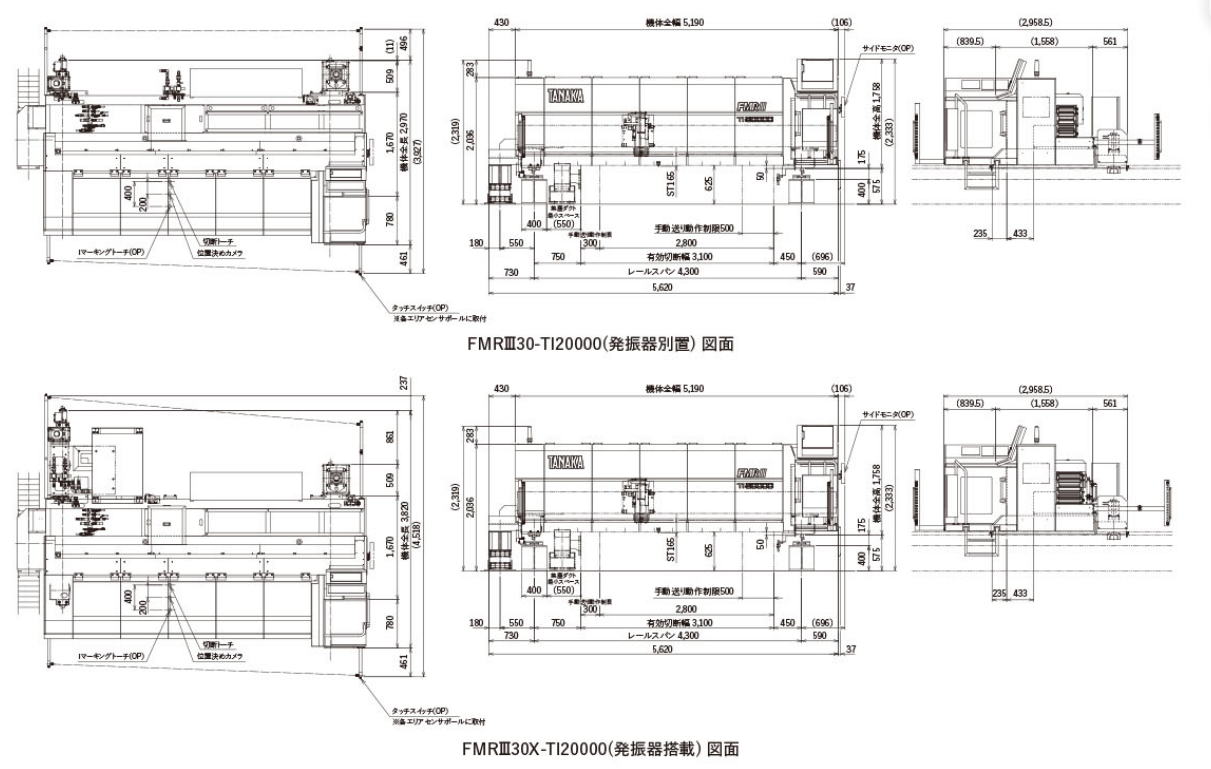

| Standard Size | 25 | 30 | 35 | 40 | 45 | 50 | 55 | |||||||

| Effective Cutting Area (mm) | 2600 | 3100 | 3600 | 4100 | 4,600 | 5,100 | 5,600 | |||||||

| Rail Span (mm) | 3500 | 3,800 | 4,000 | 4,300 | 4,500 | 4,800 | 5,000 | 5300 | 5,500 | 5,800 | 6,000 | 6,500 | 6,500 | 7,000 |

| Performance Specification | TI 12000 (12kW) | TI 20000 (20kW) |

|---|---|---|

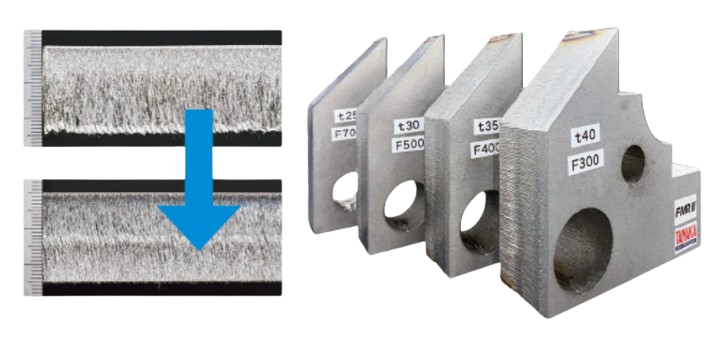

| Lens Type (RS-CW) | ~ 28mm | ~ 40mm |

| Structural Steel (SS400) | ~ 9mm | ~ 16mm |

| Stainless Steel (SUS304) | ~ 30mm | ~ 40mm |

| Aluminum (A5052) | ~ 30mm | ~ 40mm |

| Cutting Performance | |

|---|---|

| Cutting Speed | 1~24,000 mm/min |

| Rapid Traverse Speed | 36,000 mm/min |

| High-speed Rapid Traverse (Option) | 60,000 mm/min (X-axis only) |

| Cornering Speed | 24,000 mm/min |

| Minimum Cutting Speed | 12,000 mm/min |

| Head-Up Speed | 20,000 mm/min |

| Head-Down Speed | 15,000 mm/min |

| Oxygen Cutting Speed | 24,000 mm/min |

| i-Cutting Speed (Mild Steel) | 12,000 mm/min |

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka