Nissan Tanaka

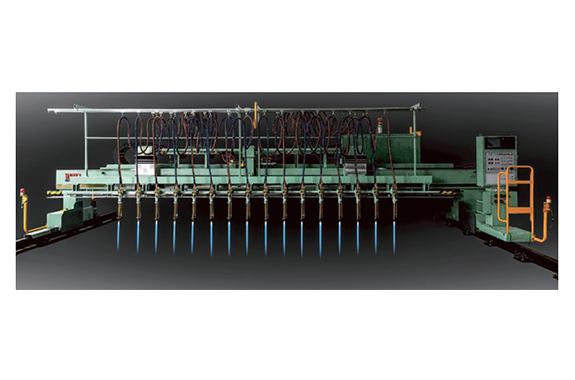

NISSAN TANAKA KT-650 NC Gas Cutting Machine

Manufacturer: Nissan Tanaka

Model : KT-650

Feature

This sentence describes the basic characteristics of the machine, emphasizing its stable dual-side rack & pinion drive and the availability of various functions.

Equipped with a well-balanced dual-side rack & pinion drive in its gantry structure, it performs high-quality, high-precision cutting. There are two types of horizontal drives available: square bar type and steel belt type, allowing for selection based on specific applications. Furthermore, adding various automation options enhances safety and operability. It comes standard with FANUC’s NC device.

Specification

| Rail Span (mm) | 4,000~8,000 | |

| Effective Cutting Width (mm) | Rail span -900 | |

| Rail Length (mm) | Standard 9,600 (Extendable in increments of 1,200) | |

| Effective Cutting Length (mm) | Rail Length: -2,500 (For a rail length of 9,600, it becomes 7,100) | |

| Horizontal Drive Method | Square Bar Method | Steel Belt Method |

| Single Torch Stroke (mm) | 1,500~2,500mm | Variable depending on the number of torches |

| Number of Blowpipes | Standard 6 units (up to a maximum of 16 units) | Standard 6 units (up to a maximum of 8 units) |

| [Automation Features] | ||

| Thick Plate Piercing Drill Device | – | ○ |

| Automatic Flame Adjustment Device | ○ | ○ |

| Torch Interval Automatic Setting Device | ○ (Seiri-kun II) | ○ (T.P.S) |

| Rapid Feed / Marking Speed (mm/min) | 18,000 | |

| NC Device | FANUC Series 0i-MODEL F Plus FANUC Series 0i-LF Plus |

|

| Drive Method | Rack & pinion drive on both sides | |

| Rail Size (kg/m) | 37 rail or 50 rail | |

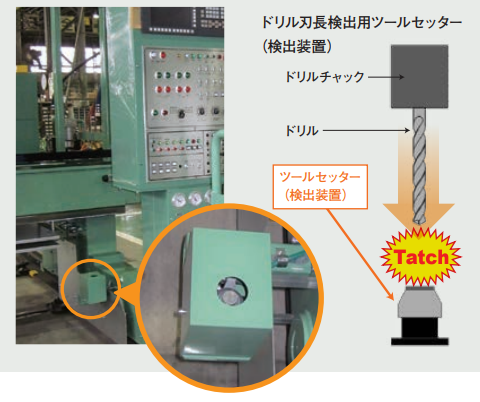

Drill Length Detection Function

Tool setter that can detect the cutting edge near the frame

Automatically detects drill blade length and sets drill conditions.

This is a function that reflects the settings.

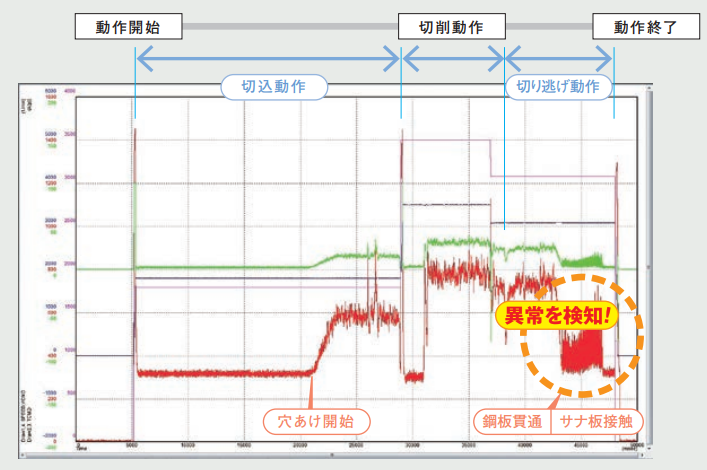

Drill Penetration Detection Function

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka

Related Products

-

NISSAN TANAKA KT-780 NC Gas Cutting Machine

-

NISSAN TANAKA S-TORR V A10 Pressure Regulator For Semiconductors

-

NISSAN TANAKA V-F22AR Pressure Regulator

-

NISSAN TANAKA ARC Cept II Ultra-high-speed Automatic Shading Face

-

NISSAN TANAKA HC-391Z/HC-338S Cutting Device

-

NISSAN TANAKA FN-1107 Fusing Laeather Gloves