Nissan Tanaka

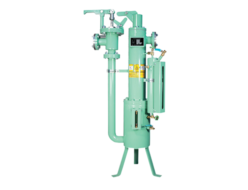

NISSAN TANAKA S-TORR V T50 Pressure Regulator For Semiconductors

Manufacturer: Nissan Tanaka

Model: S-TORR V T50

Tide diaphragm type model for liquefied gas: S-TORRⅤT50

Features

- Developers based the S-TORR regulator on the highly trusted TORR regulator, a high-purity gas pressure regulator used in semiconductor process gas lines.

- It removes screw structures from the gas contact section and applies standard electrolytic polishing to achieve very high moisture displacement characteristics and reduced particles.

- Workers weld the body and fittings, and a metal seal structure constitutes the external seal of the diaphragm section. This high external sealability ensures its safe use even with very pure gases.

- The regulator incorporates a filter in the flow path of the primary chamber to reduce internal leaks.

- Each unit undergoes a He leak test in all outgoing inspections.

- The STⅤT50 series employs a tied diaphragm style, making it robust for supplying liquefied gas.

- It removes springs from the gas contact section to reduce the risk of particle generation.

- By providing a heated supply, the regulator can accommodate gases with a vapor pressure of 1.0MPa or higher, with a maximum operating pressure of 2.5MPa.

- For corrosive gases, we have introduced the SH series which uses a Ni-Cr-Mo alloy with high corrosion resistance for the main metal parts in contact with the gas.

Basic Specifications

Use materials

Gas connection part

Main body: SUS316L

Diaphragm: SUS316L / Ni-Cr-Mo alloy (STⅤT50SH)

Filter: SUS316L / Ni-Cr-Mo alloy (STⅤT50SH)

Pressure Gauge: SUS316L

Joint or fitting: SUS316L

Other gas contact parts: SUS316L, SUS316, Fluororesin/ Ni-Cr-Mo alloy, SUS316L, Fluororesin (STⅤT50SH)

Non-contact gas part

Cap: C3604

Pressure regulating handle: ABS plastic, C3604

Performance

Inlet side maximum working pressure: 2.5MPa

Outlet side maximum working pressure: 0.6MPa

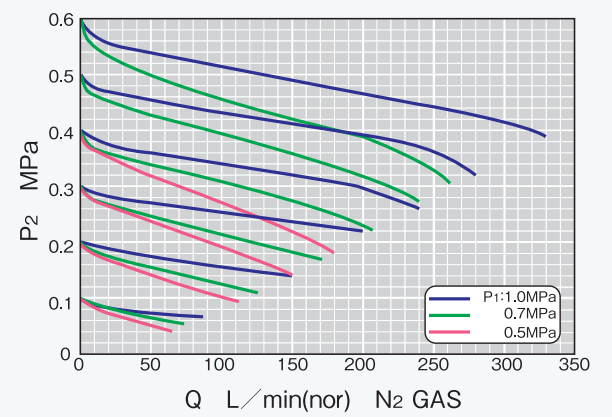

Maximum flow rate: 220L/min(nor)(P1=1.0MPa, P2=0.6MPa, N₂ GAS)

Operating temperature: -5~40℃

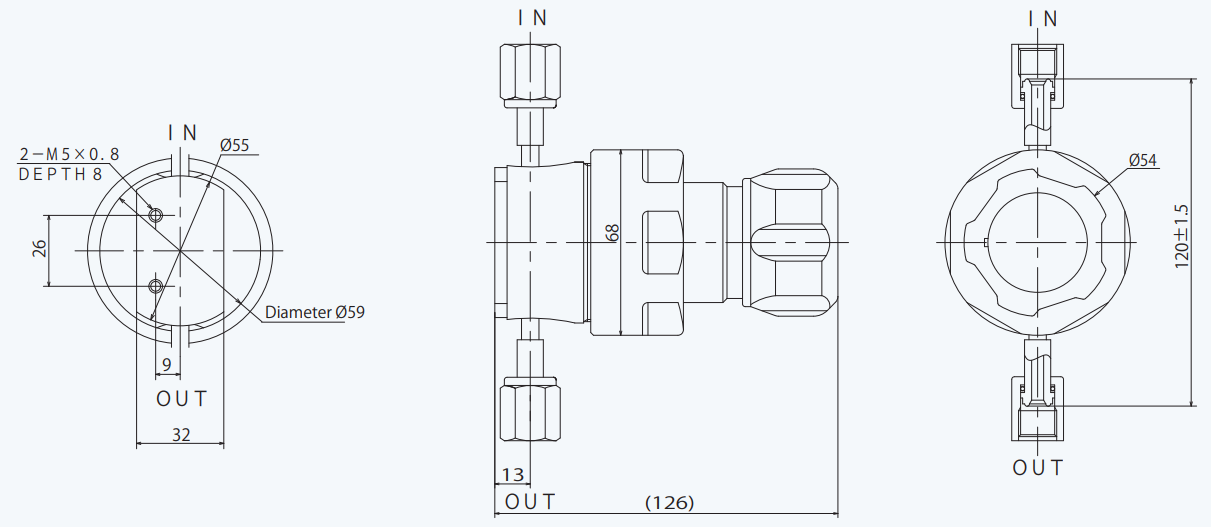

Weight: 1.8kg (2 ports), 2.0kg (3 ports)

Built-in filter filtration degree: 20μm / 10μm(STⅤT50SH)

Surface roughness of connected gas metal parts: Ra0.25μm (optional: Ra0.1μm)

Diameter of inlet and outlet ports: 1/4″

External leak amount: 1.3×10-11Pa・m3/sec below

Flow Characteristics Diagram

Appearance

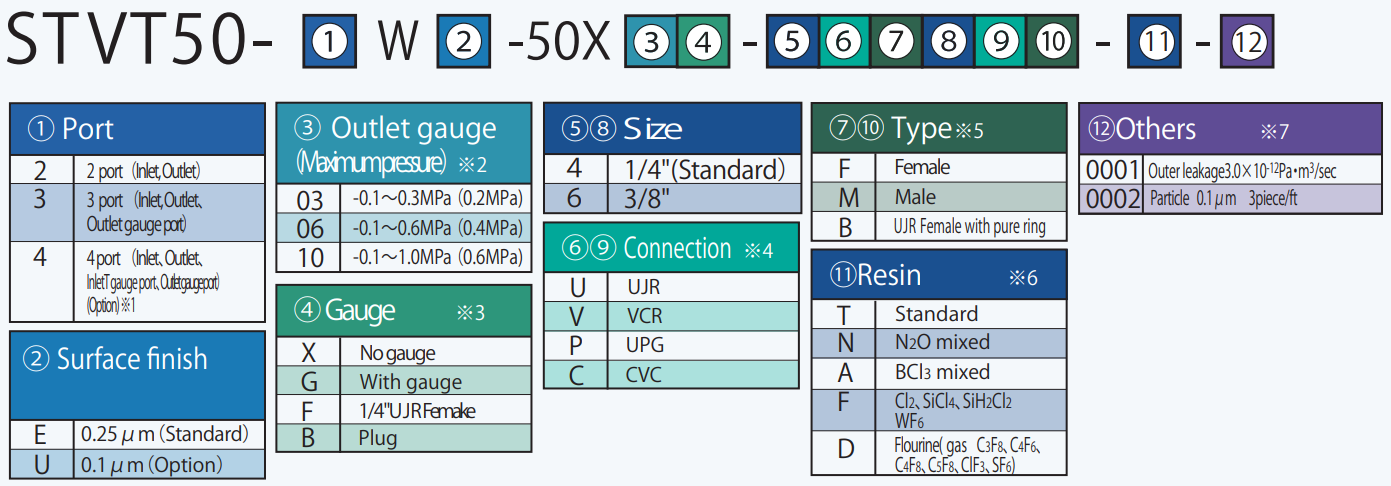

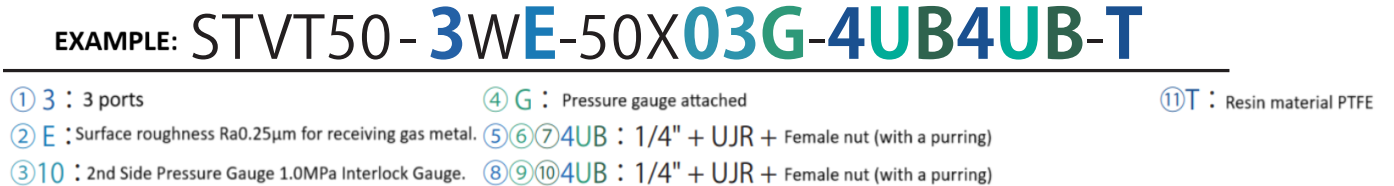

Description

Designated Attention

※1 If you select a 4-port specification, please select the symbol for the primary side pressure gauge from below and replace the product name assembly with 50X.

| Primary Side Pressure Gauge Symbol (Maximum Operating Pressure) |

03G:-0.1~0.3MPa(0.2MPa) | 30G:-0.1~3.0MPa(2.0MPa) |

|---|---|---|

| 06G:-0.1~0.6MPa(0.4MPa) | 50G:-0.1~5.0MPa(2.5MPa) | |

| 10G:-0.1~1.0MPa(0.6MPa) | 50F: Instrumentation without a pressure gauge, with a port and a fitting cap (2.5MPa) | |

| 15G:-0.1~1.5MPa(1.0MPa) | 50B: Instrumentation without a pressure gauge, with a port and a fitting plug (2.5MPa) |

※2 In the case of not having a secondary pressure gauge, the symbols for each operating

| Operating Pressure | Symbol |

|---|---|

| ~0.2MPa | 03 |

| ~0.4MPa | 06 |

| ~0.6MPa | 10 |

※3 For a 2-port version, please select ‘X’. ‘X’ indicates a product without a pressure gauge (port unprocessed). If it’s without a pressure gauge and only fittings, use ‘F’ for protection with a resin cap and ‘B’ for sealing with a metal plug.

※4 In the case of other types of fittings, other symbols will be used.

※5 For other shapes, other symbols will be used.

※6 The optimal resin for the gas contact part (nozzle) is selected for each gas used.

※7 This is an example of additional specifications. For special requirements such as specifying face-to-face dimensions, a different symbol or number will be used. Please contact us for more details.

⚠️Warning: For correct usage, please make sure to read the ‘Instruction Manual’ carefully before use.

Kouei is Distributor/Agent of Nissan Tanaka

Other items of Nissan Tanaka

Request the quotation for Nissan Tanaka

Related Products

-

NISSAN TANAKA Low Spatter Adhesion Ozzle

-

NISSAN TANAKA K, B/Z, C/S Small Cutting Machine

-

NISSAN TANAKA AU150B-H12 Ⅱ Pressure Regulator For Other Applications

-

NISSAN TANAKA TORR-80 Pressure Regulator For Semiconductors

-

NISSAN TANAKA LMZV Oscillator Controlled Laser Cutting Machine

-

NISSAN TANAKA TK-60M Medium Pressure Water Seal Safety Device