Nitolex Corporation

Nitolex Bonulex Wheels

Manufacturer: Nitolex Corporation

Model:

Hybrid Metal Bond Wheel

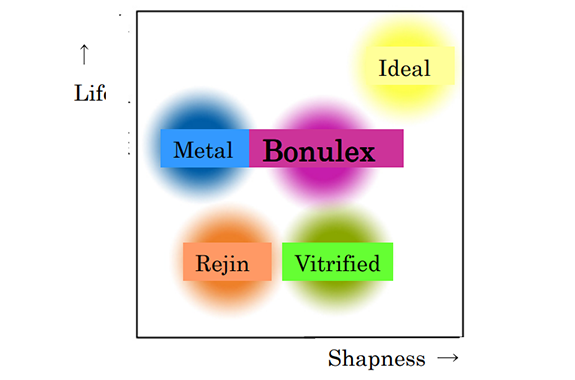

Grinding wheels one step closer to the ideal have been developed in pursuit of ideal grinding!

We have succeeded in developing a hybrid metal bond that maximizes the abrasive performance. It ensures an amazing grinding performance.

Example applications

Carbide (K-10)

Plunge grinding with surface grinder Wet type (solution)

Plunge grinding with surface grinder Wet type (solution)

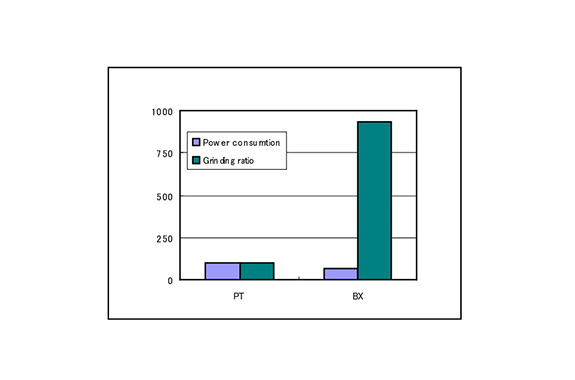

Wheel Dimensions: 3A1 150D x 10T x 50.8H x 5U x 3X

Wheel Speed:20 m/s Feed: 18 m/min Depth of cut:20µm

Test Wheel: SD 200 N 100 BX

Compared with: SDC 200 N 100 PT (Tufflex)

The grinding force required by Bonulex is a half of that required by conventional wheels and the grinding ratio obtained with Bonulex is about ten times as large as that obtained with conventional ones. Bonulex is much superior in sharpness and service life therefore able to increase the depth of cut and feed rate.

SCM

Groove grinding of automotive parts

Grinder: Special purposed machine tool

Wheel Dimensions: 14A1 200D x 10T x 50.8H x 5U x 3X

Wheel Speed: 30 m/s

Work Feed: 1.5 mm/min

Depth of cut: 3.5 mm

Test Wheel: CBN 140 N 100 BX

Compared with: CBN 120 (competitor’s metal bond)

While conventional wheels only lasted for a month, the BX wheels could be used for five months under the same conditions with no need for dressing.

Applications

1. Hevy cutting is permitted by a lower grinding

resistance.

2. The efficiency has been improved by the increased

grinding speed.

3. Superior in profile holding ability