Nitolex Corporation

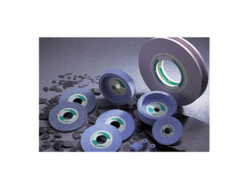

Nitolex Neovex Grinding Wheels

Manufacturer: Nitolex Corporation

Model: Neovex

Features

Functional wheels for soft materials

Non-ferrous metals grinding such as inconel, aluminum, titanium, copper or zinc alloys causes wheel loading and thus short dressing interval.

NEOVEX wheels use special abrasives and a moderately friable bond, so they avoid chip loading even when grinding soft materials. They also work well on non-metallic materials and show strong performance when grinding hard rubber, FRP, and similar materials. They adequately support various needs.

Characteristics

Wheel loading prevention

Aluminum, copper alloys such as brass and titanium alloys grind without wheel loading

Less grinding heat

When you grind hard rubber rolls cylindrically, you keep the rubber temperature low to prevent thermal degradation and thermal alteration.

Centerless grinding : stainless steel , brass shafts

Cylindrical grinding : hard rubber rolls

Creep feed grinding : turbine blades (Inconel)

Various types of precision grinding : copper, aluminum , titanium alloys.

Lead Screws (Brass) Centerless Grinding

| NEOVEX WHEELS | Conv. Wheel | |

|---|---|---|

| Wheel | NV 80 K 8 V 455X150X228.6 | GC 80 K 8 V 455X150X228.6 |

| Material | Brass (C3602) φ3.0X40L | Hardness: Hv 75 |

| Grinder | Nissin Kikai (wheel speed 33 m/s) | |

| Work speed | 1.5 m/min | |

| Dressing interval | Non-necessity | 2 – 3 hours |

| Remarks | A dressing is only once trued when it is installed while wheel life. Also it is able to grind stainless steels. | — |

Rubber Rolls Cylindrical Grinding

| NEOVEX WHEELS | Conv. Wheel | |

|---|---|---|

| Wheel | NV 60 G 11 V 305×38×101.6 | C 70 I 13 V 305×38×101.6 |

| Material | Silicon rubber, etc. | Allowance 1–1.5 mm |

| Wheel speed | 33 m/s | |

| Surface finish | 10 S | |

| Dressing interval | 2 pieces | 1 piece |

| Grinding fluid | Dry | Dry |

| Remarks | The workpiece temperature is kept at 30°C where it can be touched by hand. | The workpiece becomes 50–60°C, too hot to directly touch after grinding. |

Turbine Blades Creep Feed Grinding

| NEOVEX WHEEL | Conv. Wheel | |

|---|---|---|

| Wheel | NV 60 E 14 V 610×49×304.8 | Ceramics 803 C 15 V 610×49×304.8 |

| Material | Inconel | |

| Wheel speed | 33 m/s | |

| Depth of cut | 2.5 mm/pass | |

| Work speed | 800 mm/min | |

| Dressing interval | 1 pass | 1 pass |

| Remarks | It is equal in quality to ceramic abrasive (Sol-gel method). | — |