Japan, Nitta

Nitta Cool-off Type Intelimer™Tape

Product Made in Japan

Manufacturer: Nitta

Model: Cool-off Type

Cool-off Type

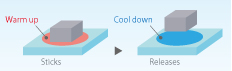

- Can be sticky by warming up to above the switching temperature.

- Can be peeled by cooling down to below the switching temperature.

- Switching temperature can be set freely between 20 and 60ºC.

The cool-off type is suitable for fixing workpiece during hot working.

Because works are readily released when cooled down by heat radiation,

the tape has been hailed for fixing ceramic devices for lamination and knife cutting processes.

HOW TO USE

- Peel the blue separator from the tape. Since the tape is not adhesive at room temperature,

heat it to 55~60°C with a hot plate or other heat source to trigger its adhesion.

Affix the tape to the target location using a rubber roller, etc.

Pass the rubber roller back and forth over the tape with little force applied 2 or 3 times.

Pressing hard with the roller will keep the tape from peeling or may leave glue on the target surface. - Use this tape for application in the temperature range of 55 to 90ºC.

- After the work is finished, wait until the workpiece and tape are cooled down to below 43ºC before peeling the tape.

Leaving at room temperature for several minutes makes it easy to peel the tape.

Do not use air-conditioner for rapid cooling.

Doing so can cause the adhesive to denature, making it hard to peel the tape.

DATA

PRECAUTIONS FOR USE

- Affixing the tape

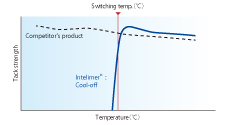

This tape becomes tacky when heated to 55°C and above,

but its adhesive force changes according to temperature,

pressure and other factors. Therefore,

test the tape before actual use. - Peeling the tape

This tape loses its tackiness at 43ºC and lower temperatures,

but its release depends on bonding conditions.

Also, note that peeling the tape above 43ºC can damage the

target surface or leave glue residue on it.

SPECIFICATION

| Product code | Switching temp. | Tack strength*2 (for stainless steel) N/25mm | Tack strength decreasing rate | Tape thickness (No separators) | Base (PET) thickness | Remarks |

| CS5040C02 | 55℃ | 5.9 | > 90% at < 40ºC | 140μm | 100μm | Single-sided type*1 |

| CS5040C05 | 1.2 | |||||

| CS5040C08 | 0.4 | |||||

| CS5025C05 | 1.2 | 125um | ||||

| CS5010C25 | 0.1 | 110μm | ||||

| CS5010C80 | 0.05< |

*1:Double-sided type also available. *2:Compliant with JIS Z0237

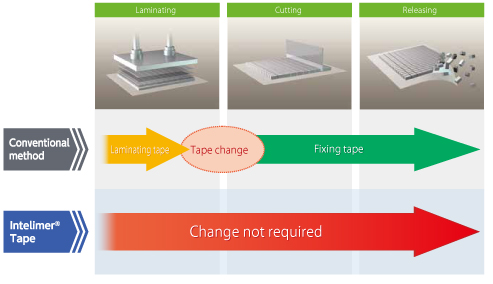

Advantages of Using Intelimer™ Tape in Electronic Device Manufacturing Processes

● Fixing green sheet (multilayer capacitors)

Intelimer™ tape is effective also for fixing workpieces in the green sheet laminating, knife cutting and dicing processes where heat is applied when workpieces are processed. In case the knife cutting process comes immediately after the laminating process, change of the carrier tape is no longer required as before. As a result, both man-hour and costs can be reduced. In addition, the good dimensional stability will contribute to improved yield, without affecting the processing accuracy.

Do you use two different tapes separately for laminating and cutting? A single Intelimer™ Tape can be used from laminating up to cutting. This not only reduces the use of tape and tape changing man-hour, but also improves processing accuracy, thus enabling significant cost reduction.

Related Products

-

Chiyoda Seiki CA-4-D1S Alarm Panel/remote Monitoring System Compact Alarm Box (Desktop Type) Share

-

Kanetec RMA-V1530 Vice Clamping Type Permanent Magnetic Chuck

-

Watanabe WSW-424C-1000 Pulse Count Node – Wireless Sensor

-

Kikusui Tape 224 Double-Coated Glue Tape

-

Hammer Caster 439G-UR Urethane Thermoplastic Wheel

-

KITO TF Series Manual Hoists