NOHMI BOSAI

NOHMI BOSAI FRRU004-GSCU Gas Suppression Control Unit

Manufacturer: NOHMI BOSAI

Model: FRRU004-GSCU

Features of FRRU004-GSCU

- One simple LED for status indication

- NFPA Class A (Styles 6 & 7) and Class B (Style 4) for SLC

- NFPA Class A (Style D) and Class B (Style B) for IDC

- Electronic address setting

- Downsized unit

- Easy installation

Description

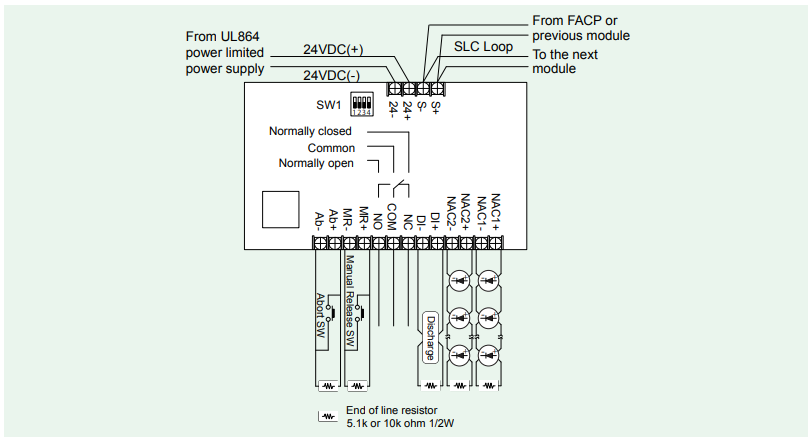

- The FRRU004-GSCU module functions as a control unit for gas suppression systems. The gas can be discharged either automatically or manually. The FRRU004-GSCU monitors the manual release switch, abort switch status, counts down to gas discharge, controls output devices, and displays the gas discharge status.Additionally, the FRRU004-GSCU has a changeover switch that allows you to select between “Auto & Manual” or “Manual Only” modes. The system continuously supervises the wiring connected to terminals NAC1, NAC2, and DI for open or short circuits, while also ensuring the presence of 24VDC power.

Specifications of FRRU004-GSCU

| No. | Item | Specification |

|---|---|---|

| 1 | Rated voltage range of SLC input power (S+, S-) | 22.0 to 24.0 V |

| 2 | Maximum SLC 24 VDC standby current (S+, S-) | 250 µA |

| 3 | Maximum SLC 24 VDC alarm current (S+, S-) | 250 µA |

| 4 | Operating voltage of external power supply line (24+,24-) | 24 VDC |

| 5 | Rating for NAC1 and NAC2 | 1.5 A per circuit |

| 6 | Rating for DI | 1.0 A |

| 7 | Rating for total of NAC1, NAC2, and DI | 3.0 A for three circuits |

| 8 | Rating for contact output | 2.0 A |

| 9 | Contact output style | Typical Form C |

| 10 | Consumption current of the board at standby | 80 mA |

| 11 | Consumption current of the board at alarm | 150 mA |

| 12 | Wiring style for NAC1, NAC2 and DI | NFPA Class B |

| 13 | End-of-line resistor for NAC1, NAC2, and DI | 5.1kΩ, 1/2W |

| 14 | Maximum wiring resistance of output circuit wiring | Refer to Wiring diagram |

| 15 | Maximum wiring capacitance of NAC1, NAC2 and DI circuit wiring | 1 µF |

| 16 | Operating temperature range | 0 to 49°C (32°F to 120°F) |

| 17 | Operating humidity range | 0 to 93% (non-condensing) |

| 18 | Address per module | 2 addresses |

| 19 | Maximum number of modules per FACP | 14 units |

| 20 | Dimensions | 145 mm (5.71″) (H) × 200 mm (7.87″) (W) × 57 mm (2.24″) (D) |

Installation

Figure 1: Installation into the ECL-GSCU-R

Figure 2: Wiring diagram of FRRU004-GSCU

Related Products

-

NOHMI BOSAI FDKU634-D-X Multi-criteria Conventional Smoke Detetor

-

NOHMI BOSAI PD Series Selector Valve

-

NOHMI BOSAI FZBU005-AIB Addressable Isolator Base

-

NOHMI BOSAI FRRJ001-Y-4F/FRRJ001-Y-16F Initiating Device Module

-

NOHMI BOSAI FDGJ Series Projected Beam Type Smoke Detector

-

NOHMI BOSAI FPI012B-1L Series Dedicate Control Panel