NOHMI BOSAI

NOHMI BOSAI Perf-EX Inside Air High Expansion System

Made in Japan

Manufacturer: NOHMI BOSAI

Model: Perf-EX

Features of Perf-EX

Foam Expansion Efficiency in Smoke Conditions

The foam expansion ratio reaches about 650 times through the aspirator method, even while aspirating smoke in the fire room. Unlike traditional high-expansion foam fire extinguishers, this method overcomes the reduction in foam expansion typically caused by smoke and hot air from combustibles.

Smoke Containment and Spread Prevention

Trapped in bubbles, the smoke stays within the fire extinguishing area, preventing spread. The foam contains and extinguishes smoke quickly. As a result, smoke spread outside the fire-extinguishing zone is minimal, allowing for faster fire response and easier evacuation, especially compared to traditional systems.

Cost Reduction and Simplified Installation

This system eliminates the need for external air intakes and outlets, reducing building costs. Unlike standard designs that require wall penetration and structural reinforcement, this system avoids increasing internal pressure. The lightweight and compact design of the inside air system also allows decentralized ceiling installation, adding more flexibility in various building types.

System specification

| Item | Specification | |

|---|---|---|

| Application | Tyre warehouses, aircraft hangers, hazardous material handling areas, etc. | |

| Generator | ||

| Method | Aspirator method | |

| Flow rate | 40~320ℓ/min at 0.49MPa | |

| Rated pressure | 0.49~0.65MPa | |

| Foam expansion rate | 650 times | |

| Foam agent | Special Foam Fire Extinguishing Agent IH-101 (No.25-1) (No.22-2) | |

| Mixture ratio | 5% | |

| Mixed method | Pressure proportioner system | |

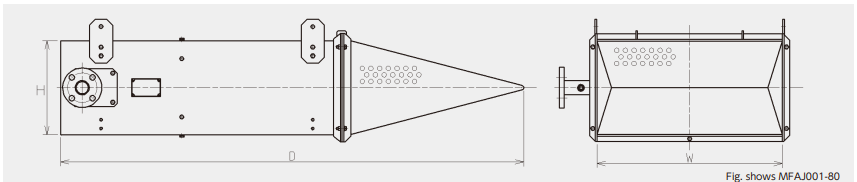

Foam generator specifications

| Type | Flow rate (L/min) | Foam expansion rate in smoke condition | Dimensions (WxHxDmm) |

|---|---|---|---|

| MFAJ001-40 | 40 | 650 times | 320x322x1600 |

| MFAJ001-80 | 80 | 650 times | 640x322x1600 |

| MFAJ001-160 | 160 | 650 times | 1280x322x1600 |

| MFAJ001-320 | 320 | 650 times | 1280x642x1600 |

Outline drawing of foam generator

Component of Perf-EX