Japan, Obishi Keiki

Obishi Keiki Seisakusho QB-101 Groove Precision Measurement System

Made in Japan

Manufacturer : Obishi Keiki Seisakusho

Model : QB-101

Measurement System Outline

On the cylindrical work edge surface, the cylindircal center standard is divided equally (2~12 portions) and the processed minute width groove shape or machining data data is measured.

Because the actual work groove width 0.8~2.0mm is very small, measurement that is not possible with general purpose 3 dimensional measuring equipment is performed automatically and accurately using special precision positioning stage and 32 bit computer. Also using sensing mechanism and special feeler and 2 pcs of 0.1μm resolution sensors, due to automatic correction computing, high precision measurement that reduces feeler deflection and error is performed and the measurement accuracy guarranteed.

Specification Outline

1 ) General Specifications

- Power AC100V±5%, 50/60Hz, 200VA

- Air Source 5kg/cm2 ~ 9kg/cm2 Clean air

- Use Environment Room

- Temperature : 20°C±5°C

- Humidity : 80%RH and below

2 ) Accuracy Warranty

- Groove Width : ±1μm and below

- Groove Width Parallellism : 1μm and below

- Groove Width Squareness : 1μm and below

- Groove Partition Angle : ±30 Angle seconds

- Groove Inclination Angle : ±1 degre

- Shape diagram :

(Lateral Magnification×20,×50 selection)

(Vertical Magnification×200,×500 selection)

(Inclination Angle Correction Enable/Disable Selection)

Related Products

-

Okabe A60-0010 Cable Protection Bridge

-

Chiyoda Seiki CK-570K Small Gas Heater/Installation Type Carbon Dioxide Heater For Equipment

-

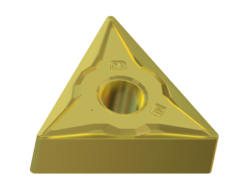

SAKUSAKU TNMG160404-MF Turning Insert 60° Triangular/Negative

-

Kimoto Bollard Rubber Products

-

Orientalmotor DRII Series Compact Electric Cylinder, CVD Series Pulse Train Input Type

-

Eisen SPT Series Limit Screw Gauge