Okabe

Okabe B30-0010 Shoring Prop

Product Made in Japan

Manufacturer: Okabe

Model: B30-0010

Length-adjustable prop

Shortened Sample

| Allowable bearing capacity of Shoring Prop (kN) | |||||

|---|---|---|---|---|---|

| Material conditions |

With braces |

Without braces | |||

| Available height (m) | |||||

| 2 or less | 2〜2.5 | 2.5〜3 | 3〜3.4 | ||

| Top and bottom ends: Wood | 19.6 | 19.6 | 17.6 | 13.7 | 9.8 |

| Top end: Wood | 19.6 | 19.6 | 18.6 | 16.6 | 14.7 |

| Bottom end: Finished concrete | |||||

(Note) “With braces” in the above table means “the product has reinforced with horizontal braces in 2 directions for each height of 2m or less using metal fasteners.”

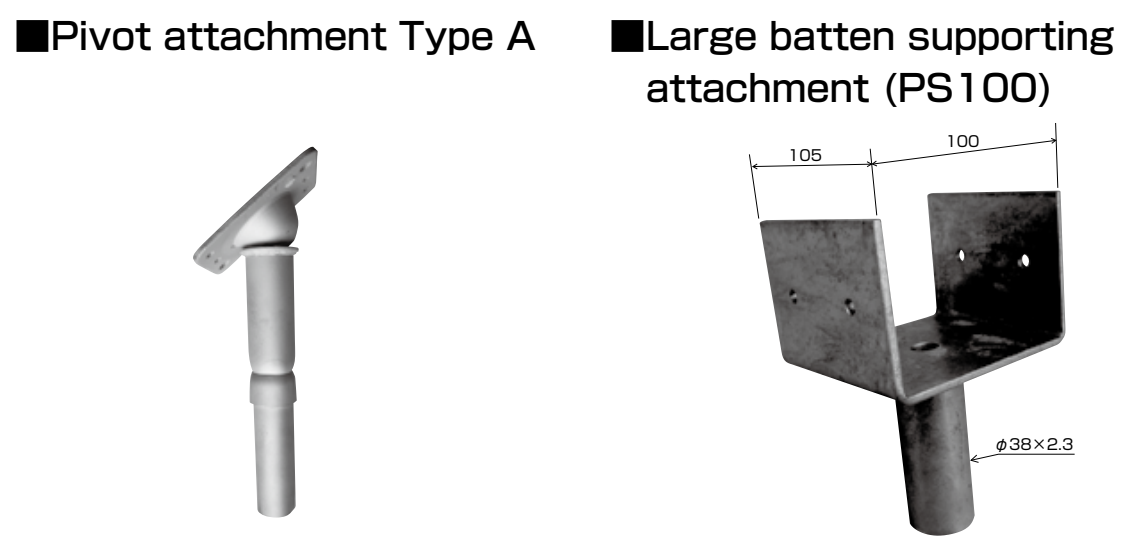

Shape & dimensional drawing

Specs

| Product | Symbol | Usable Length (mm) |

Weight (kg/pc) |

|---|---|---|---|

| Shoring Prop |

10S | 320〜430 | 4.6 |

| 12S | 370〜505 | 5.0 | |

| 15S | 470〜640 | 5.6 | |

| 20S | 600〜950 | 6.0 | |

| 30S | 810〜1275 | 7.5 | |

| 40S | 1230〜1960 | 10.0 | |

| 50S | 1535〜2570 | 11.5 | |

| 60S | 1780〜3055 | 13.0 | |

| 75S | 2150〜3425 | 14.0 | |

| 90S | 2650〜3915 | 15.0 | |

| Extension | 4S | 1200 | 5.1 |

| 5S | 1500 | 6.0 |

*The minimum usable length included adjustment lengh (+15mm).

*Effective restraint, achieved by installing horizontal pipes in two directions for each 2 meters or less of product height and preventing their displacement, allows the allowable bearing capacity to reach 19.6kN regardless of product height.

*Connecting an extension or other equipment to the product will cause the height to exceed 3.6 meters. In this case, only if effective restraint is provided by installing horizontal pipes, will the allowable bearing capacity be 19.6kN.

Cautions

- When connecting the products, install swing preventive braces and diagonal braces, if there is a risk of impact or eccentric loading.

- Ensure the product’s support plate receives a uniform load. Avoid eccentric loading.

- Inspect the product for dents. If any are found, discontinue use.

- Never attempt repairs using heat, as this weakens the product.

- Refrain from using the product in conjunction with timber pillars. This combination is dangerous because it compromises the allowable load.

- Check the following before work:

– Inspect the support plate and base plate for any bends.

– Examine the pipe for any bends, dents, or damage.

– Verify that the pin is straight.

– Check the threaded pipe for any bends.

– Conditions of accessories