Okabe

Okabe B50-0210 Achilles Thermal Insulation Board

Product Made in Japan

Manufacturer: Okabe

Model: B50-0210

Concrete-panel-free thermal insulation board

| Product | Thickness (mm) | Width (mm) | Length (mm) |

|---|---|---|---|

| Vertical use NK-20 | 20 | 900 1200 | 1800 ~ 5000 |

| NK-25 | 25 | ||

| NK-30 | 30 | ||

| Horizontal use (for slab) S-25 | 25 | ||

| S-30 | 30 |

Features

● Works as formwork panels.

● Solidly made, and the wide-spaced batten pitch of 200~250mm available.

● Contributes to energy saving provided by superior insulation performance of the hard polyurethane foam.

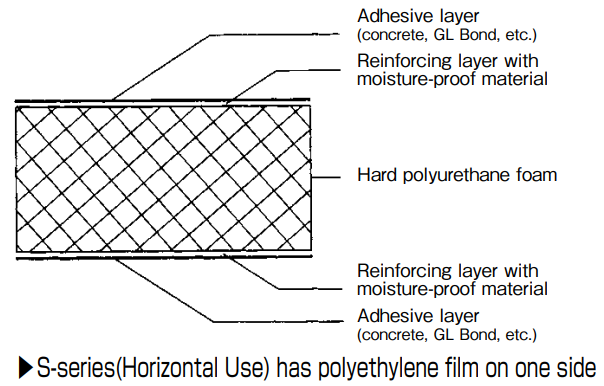

Product structure

Adhesion performance of Achilles Thermal Insulation Board

| Adherend | Unit | Material age | |||

|---|---|---|---|---|---|

| 3 days | 7 days | 28 days | 60 days | ||

| Concrete | N (kgf/cm3) | Average 12.7 (1.3) | Average 13.7 (1.4) | Average 13.7 (1.4) | Average 19.6 (2.0) |

| GL Bond | N (kgf/cm3) | Average 13.7 (1.4) | Average 13.7 (1.4) | Average 14.7 (1.5) | Average 19.6 (2.0) |

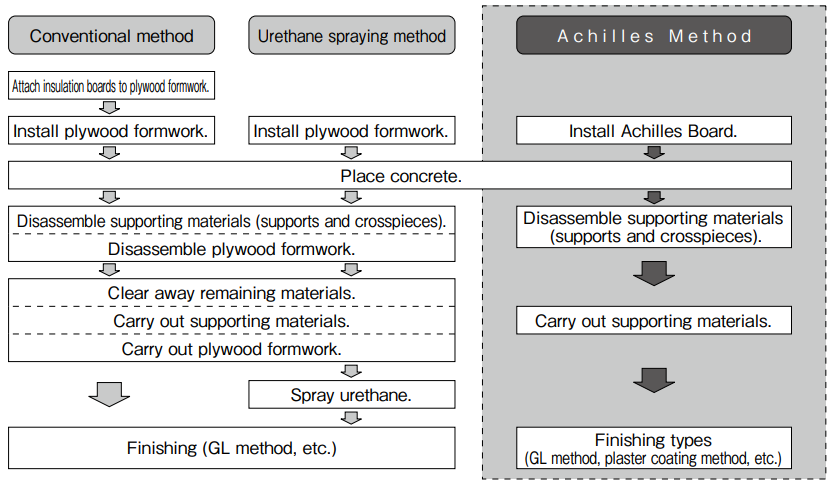

Comparison

Specs

| Item | Unit | Performance | Remarks | |||||

|---|---|---|---|---|---|---|---|---|

| Vertical Use (NK-series) | Horizontal Use (S-series) | |||||||

| 20mm | 25mm | 30mm | 25mm | 30mm | ||||

| Form density | Kg/m3 | 55 | ← | ← | 37 | 34 | ||

| Weight | Kg/㎡ | 2.78 | 3.06 | 3.34 | 1.73 | 1.86 | ||

| Thermal conductivity | kcal/mh℃ | 0.018 | ← | ← | ← | ← | Compliant with ASTM C518 (O℃) | |

| Flexural rigidity (El value) | Longitudinal direction | kN/c㎡(kgf/c㎡) | 94.0 (0.96 x 104) | 147 (1.50×104) | 211.0 (2.16×104) | 92.0(0.94×104) | 132.0(1.35×104) | Compliant with JIS A 1414 |

| width direction | kN/c㎡(kgf/c㎡) | 39.0 (0.40 x 104) | 61.7(0.63×104) | 88.0 (0.90 x 104) | 38.0(0.39x 104) | 54.0(0.56×104) | ||

| Shearing rigidity | kN(kgf) | 1.42(145) | 1.7(180) | 2.1(215) | 1.0(110) | 1.1(120) | Compliant with ASTM D 732 | |

| Compressive strength | kN/c㎡(kgf/c㎡) | 0.44(4.5) | ← | ← | 0.24(2.5) | 0.19(2.0) | Compliant with JIS A9514 | |

| Allowable bending stress | Longitudinal direction | kN/c㎡(kgf/c㎡) | 1.17(120) | ← | ← | 1.06(109) | ← | |

| width direction | kN/c㎡(kgf/c㎡) | 0.63(65) | ← | ← | 0.55(57) | ← | ||

| Vapor resistance | ㎡・h・mmHg/g | Over 600 | ← | ← | Over 400 | ← | Compliant with JIS Z 0208 | |

Option Parts

S Jointer

・Form Tie with 3-Shaped Rib

・Plastic Nail

・Achilles Board tape

・Board insert

・Resin cap

・V cutter for corner

・Floor transition materials for inner/ outer corners

・Board Keeper

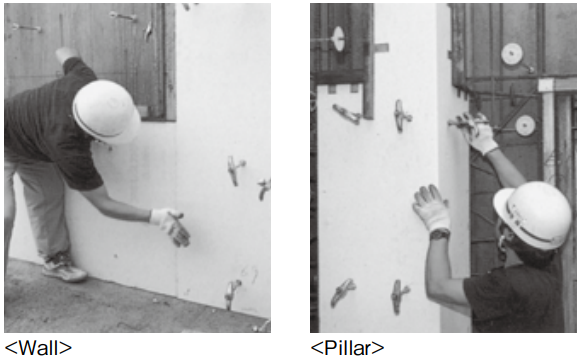

Example of vertical supports

Work examples

Cautions

● Transport the product with care to avoid corner chipping and surface damage.

● Place the product flatly on a level plane near the installation place.

● As a precautionary measure, cover the products with a sheet, etc., to prevent exposure to direct sunlight and rain.

● Do Not weld nor fuse the installed product. If welding or fusing are inevitably required during the construction process, pay sufficient attention. Make sure to prepare a fireproof sheet and fire extinguisher, and perform welding or fusing in the presence of a supervisor.

● In exterior wall finishing, dry the concrete as much as possible before applying exterior walls, particularly if they are hardly breathable.

* Dry concrete until its moisture content becomes approximately 10% or less