Okabe

Okabe B90-0210 Sliton

Product Made in Japan

Manufacturer: Okabe

Model: B90-0210

Slit material for column & wall

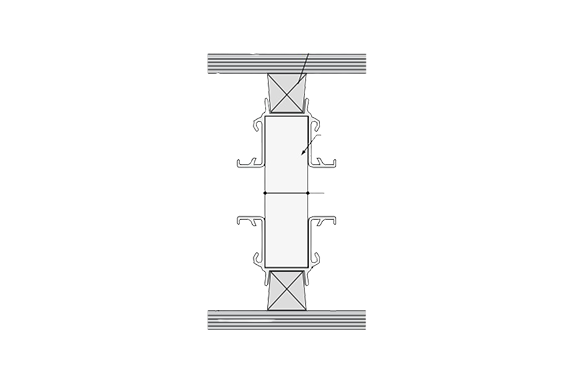

Sliton Type A (vertical complete slit type)

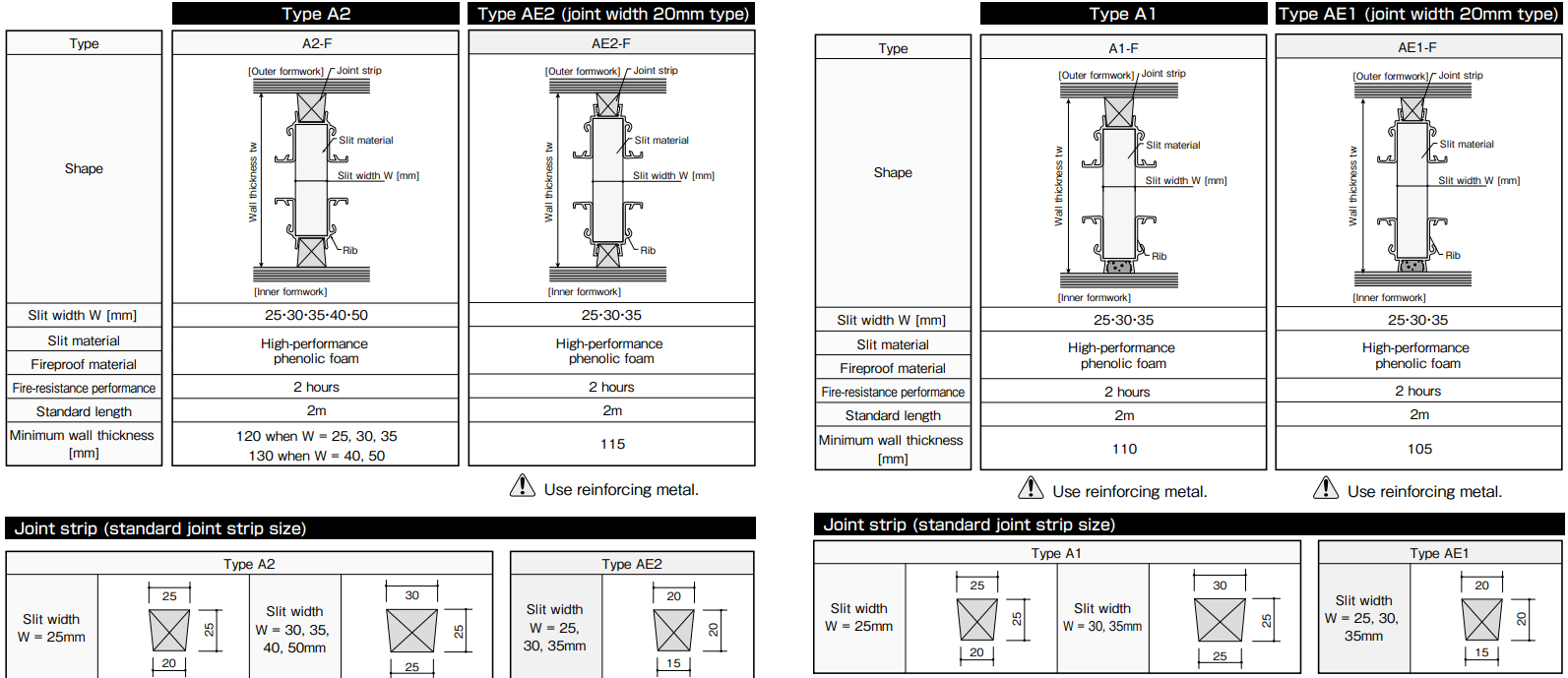

* Be sure to consult with us when applying different sizes of strips of its size.

⚠️ The sealing depth may not be secured when applying an unlisted joint strip.

Features

Type A2

● Meets all the requirements of fireproof, soundproof, and waterproof standards.

● High-performance phenolic foam (foam based on phenolic resins produced without using Freon gas) is an environment-friendly material with excellent heat, fire, and chemical resistance.

● Shaped to be positioned between joint strips so that deformation due to lateral pressure can be reduced.

● Reinforcing metals can be used together, making installation with higher precision possible.

● The flashing functionality of ribs provides excellent water cut-off performance.

Type A1

● Meets all the requirements of fireproof, soundproof, and waterproof standards.

● High-performance phenolic foam (foam based on phenolic resins produced without using Freon gas) is an environment-friendly

material with excellent heat, fire, and chemical resistance.

● Optimum in case Sliton is concealed when the interior wall is finished.

● The flashing functionality of ribs provides excellent water cut-off performance.

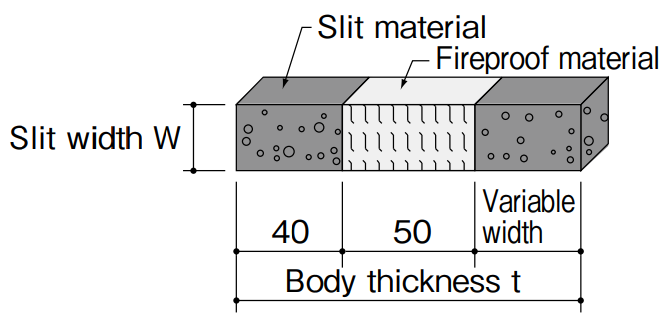

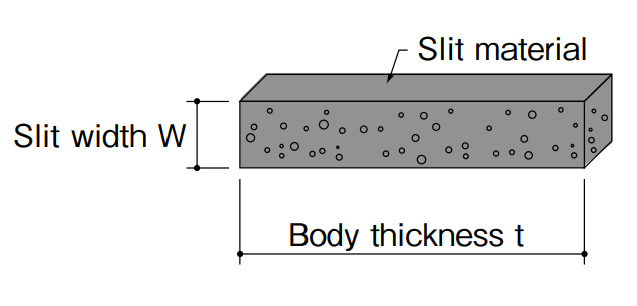

Sliton Type HW (horizontal complete slit type)

| Type | HW-RW*1 | HW-P |

|---|---|---|

| Shape |  |  |

| Slit width W [mm] | 20・25・30・35・40・50 | 20・25・30・35・40・50 |

| Slit material | Polyethylene foam | Polyethylene foam |

| Fireproof material | Rock wool | - |

| Fire-resistance performance | 2 hours | Non fire resistance |

| Standard length | 2m | 2m |

| Minimum body thickness t [mm] | 80*2 | 30 |

*1 When the body thickness t is less than 110mm, the dimension differs from the above.

*2 When the desired body thickness t is less than 80mm, please consult us.

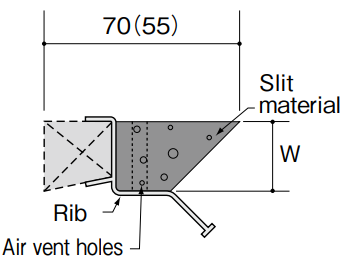

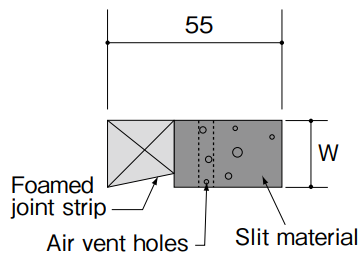

Sliton Type HW (horizontal slit type)

| Type | HW Barrier X | HW Barrier | HW-G10 | |

|---|---|---|---|---|

| Shape |  |  |  | |

| Slit width W [mm] | 25 | 20・25 | 20・25・30・35・40・50 | |

| Standard joint strip size | For W20 | - | 20×20×15(Separate) | 20×20×15(Included) |

| For W25 | 25×25×20(Separate) | 25×25×20(Separate) | 25×25×20(Included) | |

| For 30, 35, 40, 50 | - | - | 30×25×25(Included) | |

| Accessories | 10 cut nails | 10 cut nails | 10 cut nails, foamed joint strip | |

| Standard length | 2m | 2m | 2m | |

| Product dimensions [mm] | 55*1 | 55 when W=20*1 70 when W=25*1 | 55*1*2 | |

*1 HW auxiliary materials may have cross-sectional defective areas. Please confirm with the structural engineer prior to use.

*2 When combined with diagonal cut type (type C), the product dimensions are 55 → 65 (with W=35), 55 → 70 (with W=40), and 55 → 80 (with W=50).

Features

Type HW

● Meets all the requirements of fireproof, soundproof, and waterproof standards (except type P regarding fireproof).

● Complete (thorough) slit and partial slit are possible depending on the adopted dimension.

● Excellent one-site workability.

● Options are available such as cut type and waterproof type.

HW barrier

● For horizontal slits, 50mm of concrete cover depth can be secured (according to the Structural Slit Work and Control Manual

issued in October 2001 by the Building Contractors Society)

● Prevents “honeycombs” that tend to occur around construction joints.

● The product has air vent holes at 300mm intervals, which prevent air pockets below joints and “honeycombs,” and allow concrete filling to be confirmed visually.

● When the product is formed, a soft water stop is simultaneously formed to prevent water penetration through joints.

Sliton Type G (partial slit type)

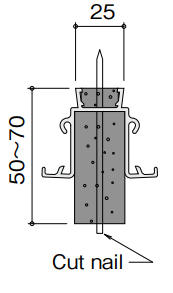

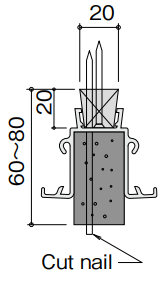

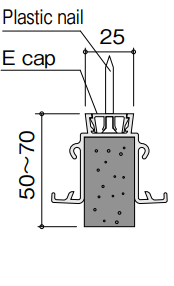

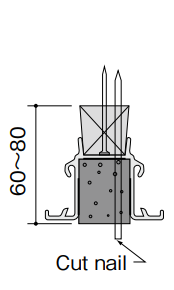

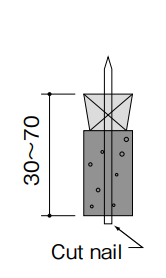

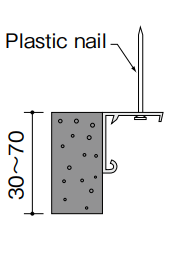

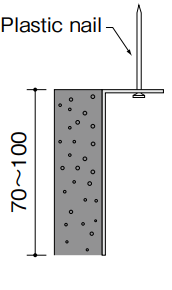

| Type | G-5 | G-6 | G-7 | G-9 | G-10 | G-11 (S) | G-11 (L) | |

|---|---|---|---|---|---|---|---|---|

| Shape |  |  |  |  |  |  |  | |

| Slit width W | 20 | - | - | - | - | ◎ Joint strip 20×15×15 | ◎ | ◎ |

| 25 | ◎ | ◎ Joint strip 20×20×15 | ◎ | ◎ Joint strip 25×25×20 | ◎ Joint strip 25×15×20 | ◎ | ◎ | |

| 30 | ◎ | ◎ Joint strip 20×20×15 | ◎ | ◎ Joint strip 30×25×25 | ◎ Joint strip 30×15×25 | ◎ | ◎ | |

| 35 | ◎ | ◎ Joint strip 20×20×15 | ◎ | ◎ Joint strip 30×25×25 | ◎ Joint strip 30×15×25 | ◎ | ◎ | |

| 40 | - | - | - | ◎ Joint strip 30×25×25 | ◎ Joint strip 30×15×25 | ◎ | ◎ | |

| 50 | - | - | - | ◎ Joint strip 30×25×25 | ◎ Joint strip 30×15×25 | ◎ | ◎ | |

| Accessories | 10 cut nails | 10 cut nails Foamed joint strip | 10 plastic nails | 10 cut nails Foamed joint strip | 10 cut nails Foamed joint strip | 10 plastic nails | 10 plastic nails | |

| t dimension*1 (Product dimension) | 50~70 | 60~80 | 50~70 | 60~80*3 65~80 | 30~70*2 | 30~70 | 70~100 | |

| Standard length | 2m | 2m | 2m | 2m | 2m | 2m | 2m | |

| Slit material/foamed polyethylene | ||||||||

⚠️ *1 When the product dimension exceeds the above dimension t, separate reinforcement is required.

*2 The minimum product dimension is 30.

*3 60~80 when 3W = 25, 30, 35

65~80 when 3W = 40, 50

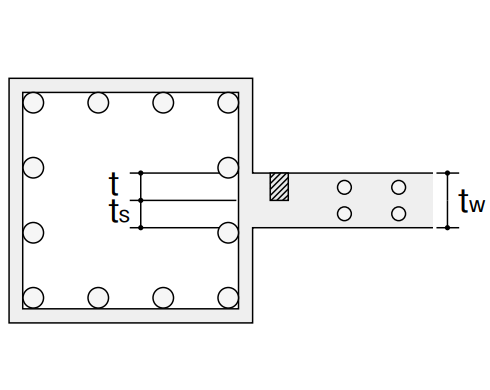

<Concept of partial slit>

When the wall thickness (tw) is 140 or less, the remaining wall thickness (ts) is tw/2 or less.

When the wall thickness (tw) is 140 or less, the remaining wall thickness (ts) is tw/2 or less.

(Example: When the wall thickness is 130, the remaining wall thickness is 65 or less, and the slit is 65 or more.)

When the wall thickness (tw) exceeds 140, the remaining wall thickness (ts) is 70 or less.

(Example: When the wall thickness is 150, the remaining wall thickness is 70 or less, and the slit is 80 or more.)

Features of type A1

● A complete (shear-type) slit is formed depending on the combination.

● Specifications are available according to fitting.

● Use of reinforcing metals makes installation with a high degree of fixation possible

Cautions

① Handling precautions

● Store the product avoiding exposure to direct sunlight and moisture.

● Avoid contact with sharp objects and corners to prevent physical damage.

● Dispose of the product in accordance with the rules and regulations of its region.

② Installation precautions

● Component materials of Sliton are combustible, except for some incombustible materials. When fire is used out of necessity, provide appropriate protection.

● Before using Sliton, be sure to confirm installation procedures, concrete placing conditions, and method, as well as precautions for each type to ensure proper use.

● Be sure to wear safety glasses and dust masks when cutting the product.

● Be careful for the protruding nails on the formwork panels.