Japan, Okabe

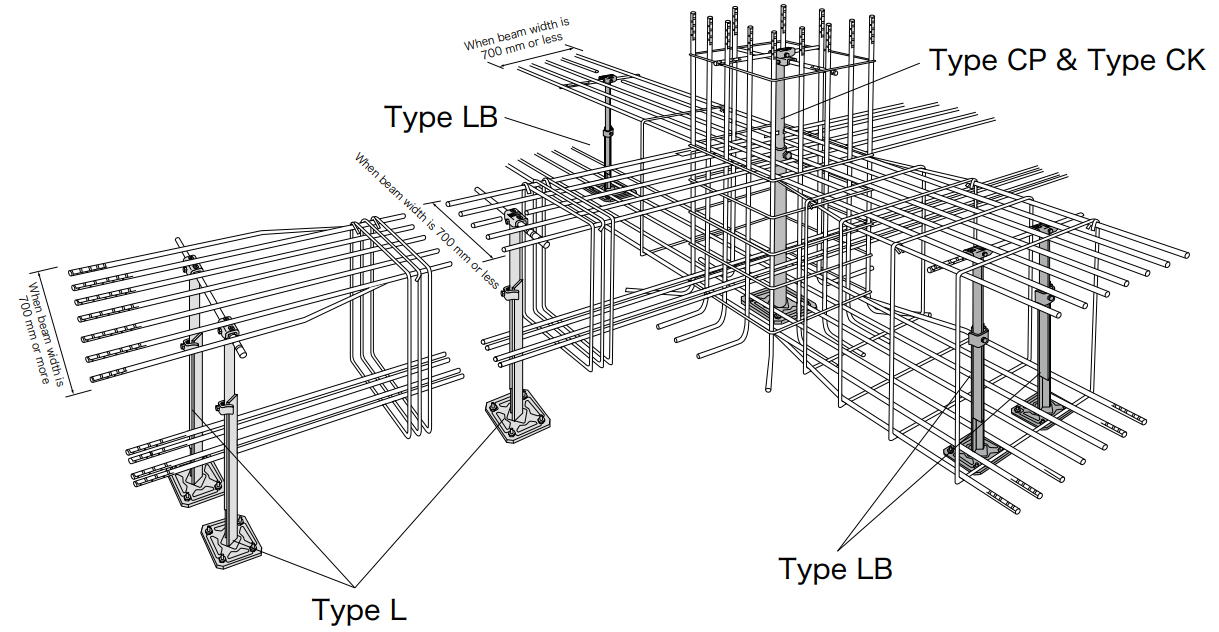

Okabe C40-0010 Footing Beam Stand

Product Made in Japan

Manufacturer: Okabe

Model: C40-0010

Rebar assembling stand for footing beam work

Features

● Scaffolding for assembling rebars is not necessary.

● Height adjustment function enables accurate rebar arrangement.

● Hairpin rebar can be easily fixed.

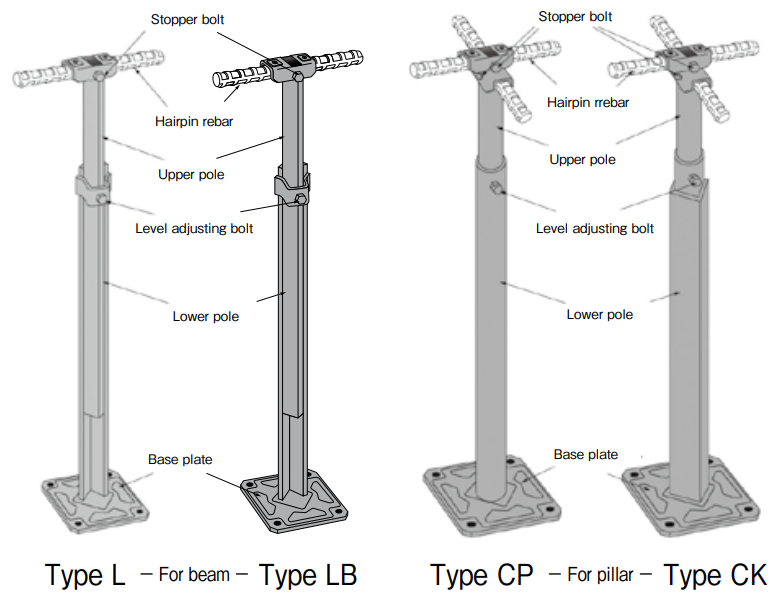

Size

| Model | Adjustment height H (mm) | Pole | Base plate size | Applicable beam width (mm) per 1 Unit | Allowable load kN (kgf) | Weight (kg/pc) | ||

|---|---|---|---|---|---|---|---|---|

| For beam | L 507 | 400- 640 | L30X30X3 | L40X40X3 | □ 150×2.6 | 700 or less | 3.92 (400) | 2.0 |

| 609 | 500- 840 | 2.3 | ||||||

| 1015 | 800-1440 | □200×2.6 | 3.3 | |||||

| 1217 | 1 1 50-1 740 | □250×2.6 | 2.94 (300) | 4.4 | ||||

| 1520 | 1450-2040 | 1.96 (200) | 4.8 | |||||

| LB1520 | 1150-2130 | L40X40X3 | L50X50X4 | 3.92 (400) | 5.4 | |||

| 1625 | 1550-2540 | 2.94 (300) | 6.8 | |||||

| 2030 | 1880-3140 | L40X40X5 | 10.0 | |||||

| For pillar | CP1625 | 1550-2540 | φ34X2.3 | φ42.7X2.3 | □250X3.2 | 800 or less | 3.92 (400) | 7.1 |

| 2030 | 1850-3170 | 8.1 | ||||||

| CK2035 | 2050-3590 | □50X50X2.3 | 1 1.1 | |||||

Use D25 hairpin rebar (not included in the product configuration).

Cautions

● The vertical load allowed for each product is up to the above-mentioned “allowable load.”

● Be sure to align the top-end level of all products so that they will receive a uniform load.

● Perform plumbing and correction of the product before arranging reinforcement.

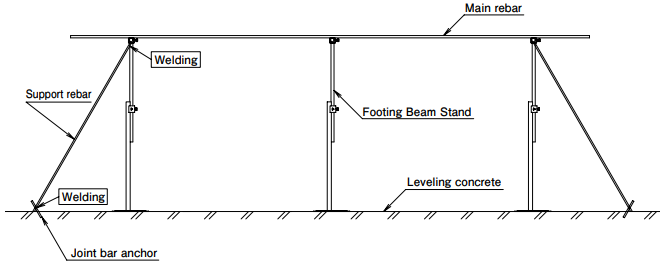

● Arrange the product vertically through the use of a stay bar, etc., to prevent lateral movement as shown in Fig. 1.

● Do Not use the product as scaffolding.

● Precautions for arrangement

– Space the products so that they will not receive a load that exceeds the allowable load.

– Supporting the product is complicated where beam reinforcements are crossed or around pillars. Therefore, be sure to examine the load before arranging the product.

– The top end of the leveling concrete on which the baseplate is installed should be finished level.

– Be sure to secure the baseplate with four anchor bolts.

– Cure the leveling concrete until its compressive strength is enough to obtain the predetermined anchor bolt strength.

– Tighten the level adjusting bolt with a tightening torque of approximately 2.94kN・cm (300kgf・cm). In case the bolt may be loosened due to vibration, etc., reinforce the bolt by welding.

[Example of reinforcement of level load]

Main reinforcement supporting stand for small footing beam work

Features

● Rebars (D25) on-site can be used.

● Hairpin rebar can be mounted easily with a 3/8” spanner.

● Deformed bars (D25, D22) can be used as hairpin rebar.

● Hairpin rebar can be fixed at any position (height).

● After marking, the product can be fixed at a precise position by using the product base.

Allowable load: 2.94kN(300kgf)

| Product | Weight (kg/pc) | Quantity (pc/bag) | Weight (kg/bag) | Packing |

|---|---|---|---|---|

| Stand | 0.50 | 50 | 25 | PP bag |

| Base Plate | 0.85 | – | – | – |

* D29 is also available as Made-To-Order.

Cautions:

● Use a rebar (D25) as a bracing strut bar.

● Secure the product base firmly to the leveling concrete with concrete anchors or concrete nails.

● Use the product where beam height is 1m or less and width is 400mm or less.

● Be sure to use the product within the allowable load

Related Products

-

Kitz Class 150 Bronze Y-Pattern Swing Check Valve

-

KONAN MVW7N-04-D 3 Port Solenoid Valves Large-Capacity Poppet-type Normally Closed (Hold)

-

Furuto Industrial (Monf) No.801A Cloth Adhesive Tape

-

Seiwa E04FD070504 Ferrite Cores for FPC FD Type EMC Products

-

Nihon Flux Standard Type

-

DIJET SDHW1504ADEN-F1 Thin Plate Insert For FJM/FJM-F4 Type