Okazaki Seiko

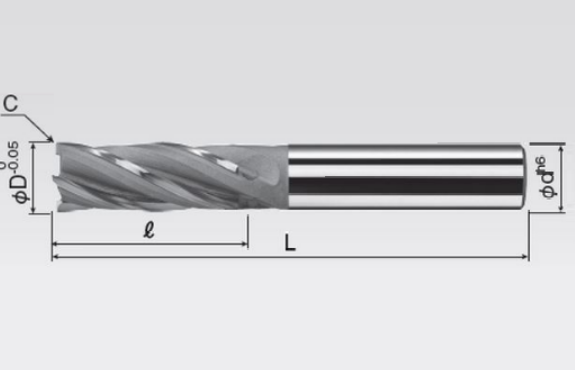

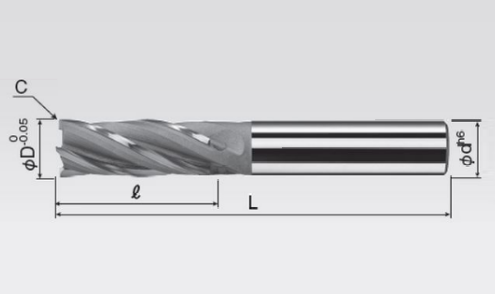

Okazaki Seiko BPD4L Brazed Long Square Endmills (4 Flutes)

Manufacturer: Okazaki Seiko

Model: BPD4L

By micro grain carbide (Z-10), it can process materials from cast-iron to steels.

Specification

| Product No. | Size | |||

|---|---|---|---|---|

| Cutting Diameter (D) | Blade Length (ℓ) | Overall Length (L) | Shank Diameter (d) | |

| BPD4L200F | 20 | 55 | 140 | 20 |

| BPD4L250F | 25 | 70 | 170 | 25 |

| BPD4L300F | 30 | 85 | 200 | 32 |

| BPD4L320F | 32 | 85 | 200 | 32 |

| Product No. | Size | |||

|---|---|---|---|---|

| Cutting Diameter (D) | Blade Length (ℓ) | Overall Length (L) | Shank Diameter (d) | |

| BPD4L350F | 35 | 85 | 200 | 32 |

| BPD4L400F | 40 | 100 | 215 | 32 |

| BPD4L450F | 45 | 100 | 215 | 42 |

| BPD4L500F | 50 | 125 | 240 | 42 |

Recommended Milling Conditions

| Material | General Steel, Carbon Steel, Alloy Steel, Tool Steel SS400, S55C, SCM, SK, SKD | Cast Iron (FC) | Soft Aluminum Alloys (A1200, A2024) | |||||||

| 〜20HRC | 〜30HRC | 〜40HRC | ||||||||

| Cutting Speed | 35〜45 m/mln | 30〜40 m/mln | 25〜30 m/mln | 35〜45 m/mm | 60〜70 m/mln | |||||

| Cutting Conditions/ Outer Diameter (mm) | Rotational Speed (rpm) | Feed Rate (mm/min) | Rotational Speed (rpm) | Feed Rate (mm/min) | Rotational Speed (rpm) | Feed Rate (mm/min) | Rotational Speed (rpm) | Feed Rate (mm/min) | Rotational Speed (rpm) | Feed Rate (mm/min) |

| 20 | 720 | 350 | 610 | 200 | 480 | 90 | 720 | 430 | 1,110 | 810 |

| 25 | 570 | 320 | 480 | 190 | 380 | 80 | 570 | 400 | 890 | 740 |

| 30 | 480 | 270 | 400 | 160 | 320 | 70 | 480 | 340 | 740 | 640 |

| 35 | 410 | 270 | 350 | 160 | 270 | 70 | 410 | 340 | 640 | 640 |

| 40 | 360 | 280 | 300 | 160 | 240 | 70 | 360 | 350 | 560 | 650 |

| 50 | 290 | 250 | 240 | 150 | 190 | 60 | 290 | 310 | 450 | 580 |

| aₚ | 1.5D | 1.5D | 1.5D | 1.5D | 1.5D | |||||

| aₑ | 0.1D | 0.1D | 0.1D | 0.1D | 0.1D | |||||

| Side Milling | Notes |

|---|---|

ap: Cutting depthae: Cutting width | Note 1: If the cutting depth is large, reduce the feed rate by approximately 20% to 30%. Note 2: Use a rigid and precise machine and holder. Note 3: Use a suitable cutting fluid appropriate for the work material. |

| Material | General Steel, Carbon Steel, Alloy Steel, Tool Steel SS400, S55C, SCM, SK, SKD | Cast Iron (FC) | Soft Aluminum Alloys (A1200, A2024) | |||||||

| 〜20HRC | 〜30HRC | 〜40HRC | ||||||||

| Cutting Speed | 30〜40 m/mln | 25〜35 m/mln | 20〜27 m/mln | 30〜40 m/mln | 55〜65 m/mln | |||||

| Cutting Conditions/ Outer Diameter (mm) | Rotational Speed (rpm) | Feed Rate (mm/min) | Rotational Speed (rpm) | Feed Rate (mm/min) | Rotational Speed (rpm) | Feed Rate (mm/min) | Rotational Speed (rpm) | Feed Rate (mm/min) | Rotational Speed (rpm) | Feed Rate (mm/min) |

| 20 | 650 | 230 | 560 | 140 | 450 | 60 | 650 | 290 | 1,020 | 540 |

| 25 | 520 | 210 | 450 | 130 | 360 | 50 | 520 | 270 | 820 | 500 |

| 30 | 440 | 190 | 370 | 120 | 300 | 50 | 440 | 240 | 680 | 460 |

| 35 | 370 | 200 | 320 | 120 | 250 | 50 | 370 | 250 | 580 | 470 |

| 40 | 330 | 190 | 280 | 110 | 220 | 50 | 330 | 240 | 510 | 440 |

| 50 | 260 | 170 | 220 | 100 | 180 | 40 | 260 | 210 | 410 | 400 |

| aₚ | 2.5D | 2.5D | 2.5D | 2.5D | 2.5D | |||||

| aₑ | 0.1D | 0.1D | 0.1D | 0.1D | 0.1D | |||||

| Side Milling | Notes |

|---|---|

ap: Cutting depthae: Cutting width | Note 1: If the cutting depth is large, reduce the feed rate by approximately 20% to 30%. Note 2: Use a rigid and precise machine and holder. Note 3: Use a suitable cutting fluid appropriate for the work material. |