OMEGA SYSTEM CO.,LTD.

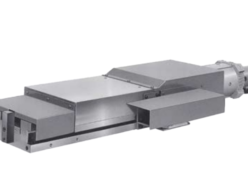

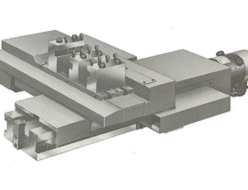

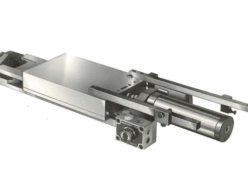

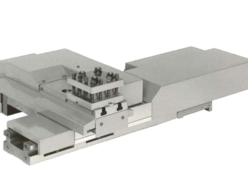

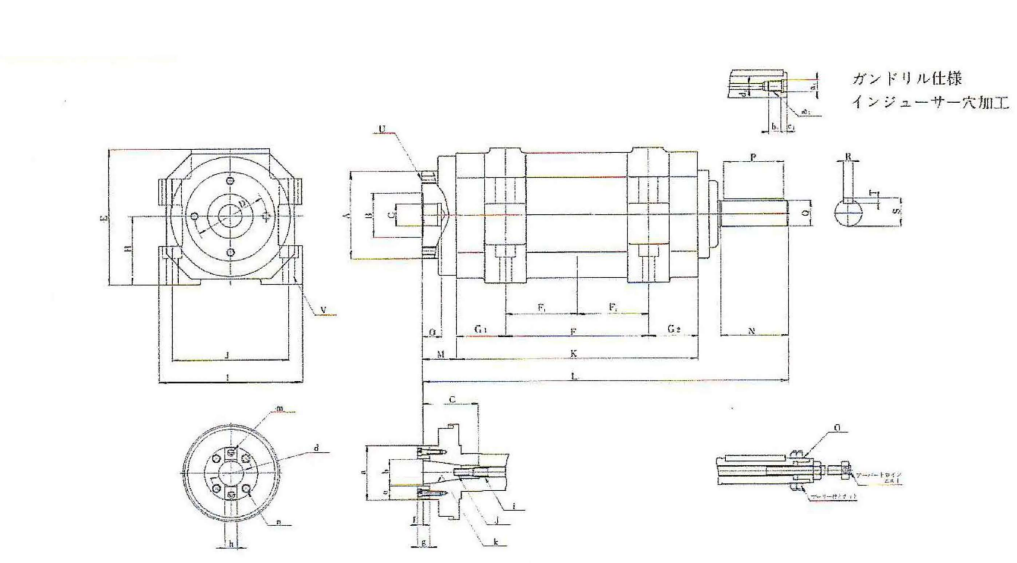

Omega System BON Series Spindle Unit

Manufacturer: Omega System

Model: BON Series

Features

- When installing the equipment, make sure that the power supply is a three-phase AC power supply (P5) and that the electrical wiring is properly completed. Also, ensure that the power supply voltage is within the allowable range.

- During operation, do not approach the machine with your hands or body. Pay attention to the moving parts and edges to avoid accidents.

- When using the pressure foot switch (7200 P5), keep your foot on the switch until the operation is completed. Do not apply excessive force to the switch.

- When using the single-operation foot switch (F type or S type), make sure to release the switch immediately after the operation is completed.

- When using the emergency stop button, press it firmly to ensure the machine stops. After the situation is resolved, turn the button in the direction of the arrow to release it before resuming operation.

- Please perform daily maintenance according to the maintenance schedule in the manual. Regular maintenance is important for ensuring the safety and longevity of the machine.

- Always turn off the main power supply (main breaker) when not in use.

Specification

| Model | Size (mm) | Bearing Model (P5 Class) | Bearing Model | Grease Nipple | Max. Rotational Speed (rpm) | JIS Standard |

|---|---|---|---|---|---|---|

| BON-25 | 25 | 7205X 2 | 7205X 2 | N 306 | 6000rpm | – |

| BON-35 | 35 | 32207 | 32206 | N 306 | 2500rpm | JIS B6101 30° |

| BON-45 | 45 | 32209 | 32208 | N 308 | 2200rpm | JIS B6101 30° |

| BON-50 | 50 | 32210 | 32209 | N 308 | 2000rpm | JIS B6101 30° |

| BON-S50 | 50 | 32210 | 32209 | N 308 | 2000rpm | JIS B6101 30° |

| BON-60 | 60 | 32212 | 32211 | N 310 | 1500rpm | JIS B6101 40° |

| BON-S60 | 60 | 32212 | 32211 | N 310 | 1500rpm | JIS B6101 40° |

| BON-80 | 80 | 32216 | 32215 | N 313 | 1000rpm | JIS B6101 50° |

| BON-S80 | 80 | 32216 | 32215 | N 313 | 1000rpm | JIS B6101 50° |

| BON-100 | 100 | 32220 | 32219 | N 317 | 800rpm | JIS B6101 50° |

| BON-120 | 120 | 32224 | 32221 | N 319 | 600rpm | JIS B6101 50° |

Other items of Omega System

Request the quotation for Omega System