Orientalmotor

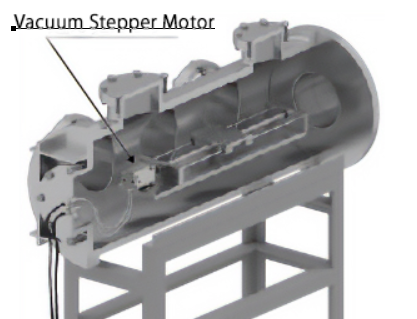

Orientalmotor AR Series Vacuum Type αSTEP

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: AR Series Vacuum Type

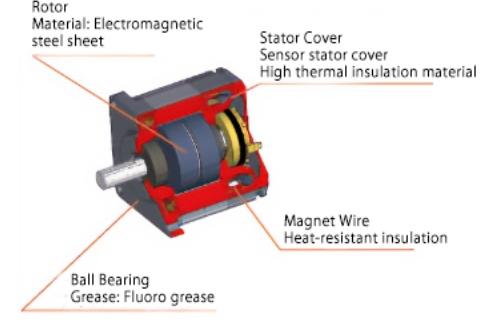

Features and structure of vacuum type motors

To reduce gas emissions, the motor case is made of aluminum and stainless steel, the surface is unpainted, and vacuum grease is used for the bearings.

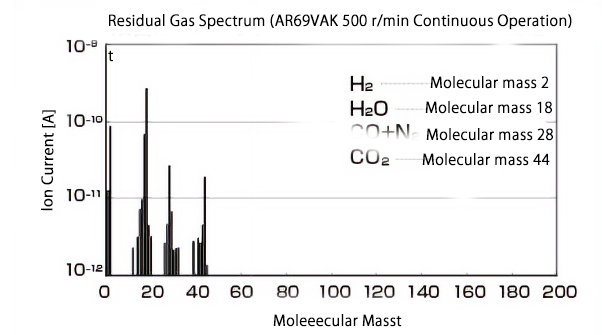

The released gases are the same as those found in normal clean environments, so there is no risk of contaminating the vacuum environment.

Heat-resistant windings are used so that the device can withstand the temperatures of the baking process.

Advantages of vacuum type motors

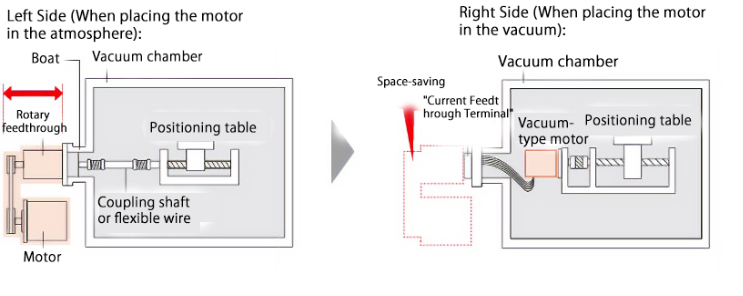

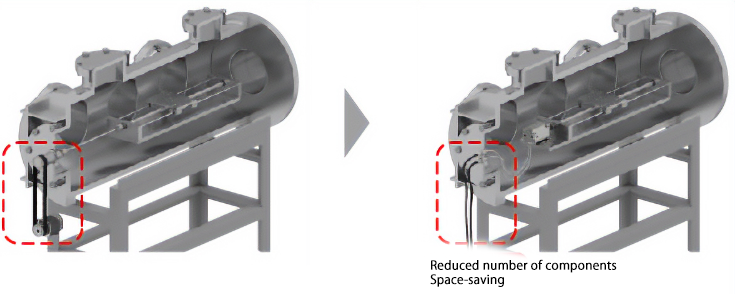

Miniaturizing the device and expanding design freedom

When installing a motor in the atmosphere, the equipment becomes large because a rotary feedthrough is used. With a vacuum type, the motor can be installed in a vacuum environment, so the equipment can be made smaller. Furthermore, the αSTEP AR series does not require a sensor for position confirmation, which contributes to cost reduction.

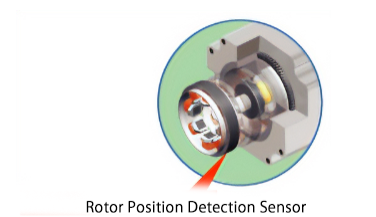

The αSTEP AR series allows position monitoring without an encoder

The αSTEP AR series monitors motor information through closed-loop control and is equipped with various alarm output functions. Expensive vacuum compatible encoders are no longer necessary.

It is equipped with a rotor position detection sensor (resolver) that detects motor information and controls the motor.

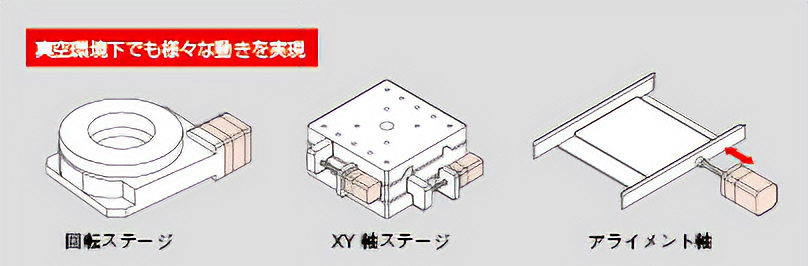

Realizing various movements in a vacuum

It is used for a variety of purposes, including semiconductor manufacturing equipment and measuring instruments such as electron microscopes.

Vacuum type motors are compatible with multi-axis stages in a vacuum environment, which is difficult to design with rotary feedthroughs. Multiple axes can be combined in a vacuum, allowing for more complex movements.

The low-loss αSTEP AR series is ideal for analysis and processing in a vacuum.

It is useful for positioning applications in vacuum environments, such as material analysis in low vacuum, high-power laser processing, and vacuum film deposition.

Contributing to maintaining the quality of the vacuum environment

Designed to reduce outgassing

To prevent gas emissions, the motor surface is not painted and vacuum grease is used for the bearings. The main residual gases are the same as those found in normal clean environments, so it can be used without worrying about contamination inside the vacuum chamber.

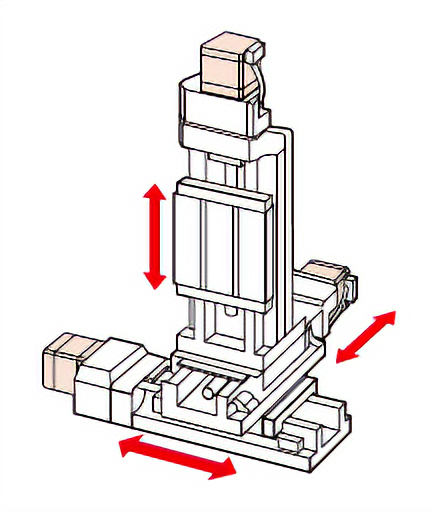

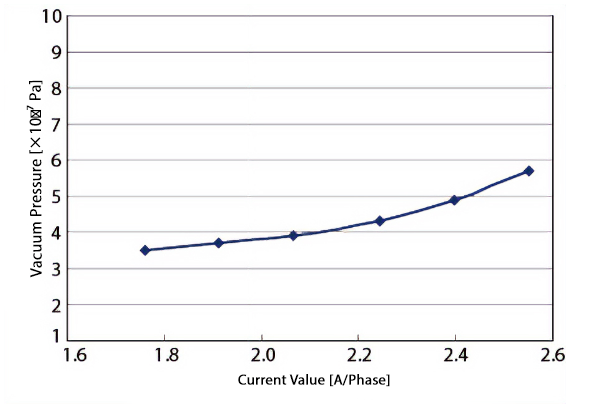

Suppresses temperature rise and maintains vacuum pressure

Generally, the vacuum pressure increases with increasing motor current. This is because the motor temperature increases and the evaporation of water increases, mainly from the windings and resin materials. To keep the vacuum pressure low, it is important to keep the motor temperature low.

Motor current increases → motor temperature increases → water evaporates from motor parts → vacuum pressure increases

The αSTEP AR series has a function (CC mode) that adjusts the motor current according to the magnitude of the load torque. When used in CC mode, the motor temperature can be kept low and the vacuum pressure can be kept low.

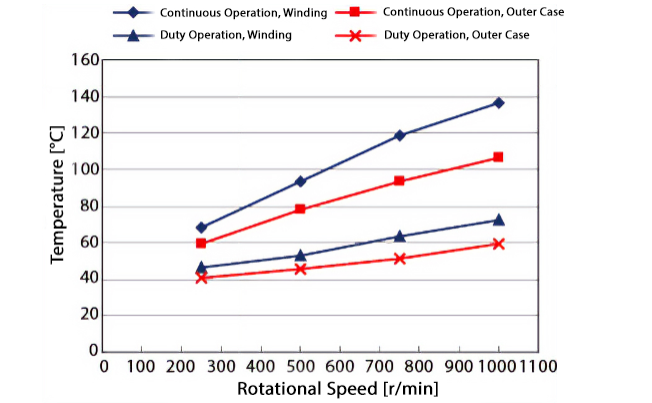

The graph below shows the rotation speed-temperature characteristics during continuous operation and duty operation (intermittent operation).

Even during continuous operation when the temperature tends to rise, the housing temperature will not exceed 100°C if the operating speed is 900 r/min or less.

Comparing the outer shell temperature during 500 r/min duty operation in each mode, it is 46°C in CC mode and 80°C in normal mode. The temperature is 34°C lower in CC mode.

Line up

| Input Power | Series name | Basic step angle [°] | Vacuum degree [Pa] | Mounting angle dimensions [mm] | Mass [kg] | List price | |||

|---|---|---|---|---|---|---|---|---|---|

| 28 | 42 | 60 | 85 | ||||||

| AC |  | 0.36 | 10 -5 | – | ● | ● | ● | 0.47 to 1.9 | From 167,300 yen (motor, driver) |

| DC | ● | ● | ● | ● | 0.2 to 3 | ||||

| DC | /CVD series driver  | 0.72 | 10 -4 | – | ● | ● | – | 0.21–1.3 | From 114,400 yen (motor, driver) |

| 10 -5 | ● | – | – | – | 0.11–0.2 | ||||