Japan, Orientalmotor

Orientalmotor BLH Series Brushless Motors

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: BLH Series

BLH Series Overview

Brushless Motor Offering a Wider Selection

Output Power

15 W/30 W/50 W/100 W

Motor Type

- Connector type/Lead wire type (IP40)

- Cable type (IP65)

- Electromagnetic brake motor (IP65)

Output Shaft Type

3 Selectable Driver Types

Analog setting type

- Speed setting with potentiometer

- I/O control of stop operation

Digital setting type

- Speed setting using support software

- I/O control of stop operation

RS-485 Communication Type

- Speed setting with Modbus protocol

- Monitoring from the host controller possible

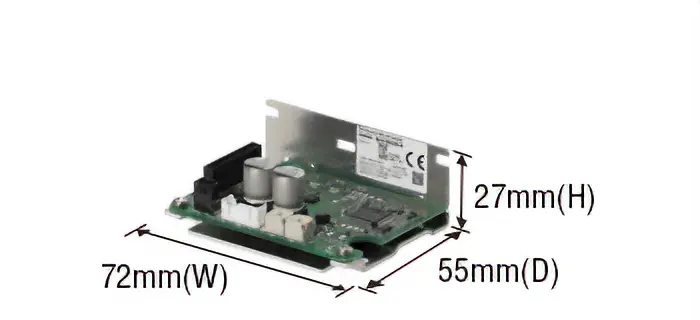

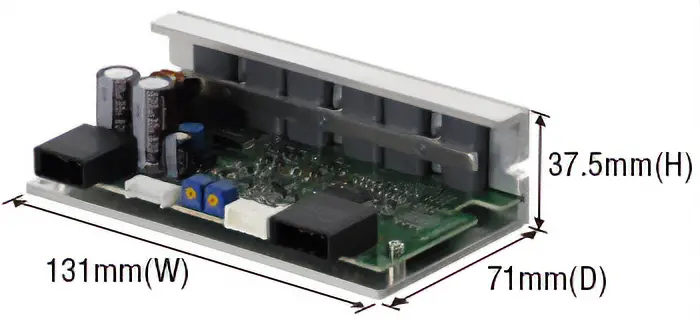

Compact, lightweight, board type

Function and Setting Method for Compact Driver

| Driver Product Line | Analog setting type | Digital setting type | RS-485 Communication Type | |

|---|---|---|---|---|

| External View |  |  |  | |

| Features | Simple speed setting with potentiometer or external analog signal | Setting up with MEXE02 support software from PC | Setting up from network via Modbus communication | |

| Output Power | 15 W/30 W/50 W/100 W | 15 W/30 W/50 W | 15 W/30 W/50 W | |

| Speed Control Range | 100~3000 r/min | 80~3000 r/min | 80~3000 r/min | |

| Speed Setting Method | Internal speed potentiometer | ● | ● | - |

| External speed potentiometer | ● | ● | ● | |

| External DC Voltage | ● | ● | ● | |

| PWM Signal | - | ● | ● | |

| MEXE02 | - | ● | ● | |

| RS-485 Communication | - | - | ● | |

| Function | Instantaneous Stop | ● | ● | ● |

| Acceleration and Deceleration Operation | ● | ● | ● | |

| Multi-Speed Operation | ● | ● | ● | |

| Multi-Motor Control | ● | ● | ● | |

| Load factor indication | - | ● | ● | |

| torque limiting | - | ● | ● | |

| Load holding function | - | ● | ● | |

| Deceleration Stop | - | ● | ● | |

| Information | - | ● | ● | |

Optimal Control Adds Plus-α Value to the Equipment

Fine speed settings and excellent speed regulation ratios allow for different types of operation.

Reduced Equipment Takt Time

Reduces takt time by shortening starting and deceleration time.

There are Two Main Factors That Reduce Takt Time in the Equipment

① Starting Time Reduction

Maximum instantaneous torque (1.5 times rated torque) reduces starting time

② Stop Time Reduction

Deceleration stop time can be set to be shorter.

Selecting Deceleration Stop Methods (Digital Setting Type and RS-485 Communication Type)

Generates brake force at a deceleration stop and stops in accordance with an arbitrarily set time.

The deceleration stop operation can be set on the MEXE02 support software.

Torque Adjustment (Digital setting type, RS-485 communication type)

A torque limiting function is provided to reduce the torque generated by the motor.

The range of maximum instantaneous torque can be set from 0 to 200 %, with 100 % at the rated torque.

The MEXE02 support software also allows you to monitor the load factor and output information at an arbitrarily set threshold (torque value).

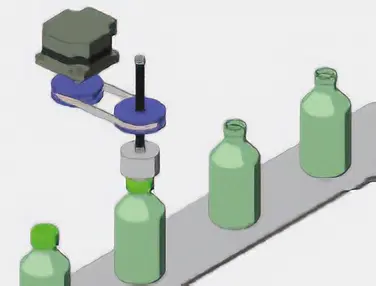

Applications

Adjusting the tightening force

Pressurization in pressing applications (Pushing)

· Preventing damage from pinching (Low thrust)

Adjustment of gripping force

Suitable for Quiet Environments

By reviewing the drive method of driver allowed us to achieve a lower noise level compared to conventional products.

Generates a Holding Force When an External Force is Applied, Load Holding Function (Digital setting type, RS-485 communication type)

It can be used as an electrical holding brake* when stopping without a mechanical brake.

- *Holding loads up to 50 % of rated torque.

Advantages of No Mechanical Brake Mechanism

- Long life with no maintenance required due to non-wear parts

- Minimizing space usage and weight of the equipment

Note

If the power supply to the driver is turned off, the holding force dissipates. This cannot be used to prevent a fall when stopped.

Applications

Applications that frequently start and stop

A Wider Selection of Motors and Gearheads

Direct Connection via a Single Cable, No Relay Required (Connector type)

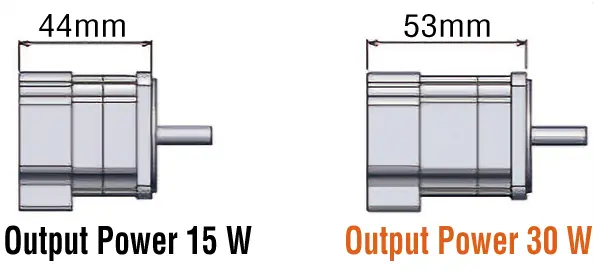

1 Rank Higher Output Power (Connector type)

One Rank Higher Output Power at the Same Mounting Angle (Frame Size:42 mm)

Model Number 1 is More Compact With the Same Output Power (Output Power: 30 W)

Standstill and Holding by Electromagnetic Brake Electromagnetic Brake Motor

The electromagnetic brake motor can hold the position during horizontal driving.

It can hold the stop position when stopping the equipment to reload or process workpieces, or hold the load in the event of blackout or other unforeseen circumstances.

Note

This product is not suitable for usages requiring vertical movement, such as gravitational operations.

Confirm Motor Stop by MOVE Output (Digital setting type, RS-485 communication type)

The MOVE output can be used to check when to turn off the electromagnetic brake.

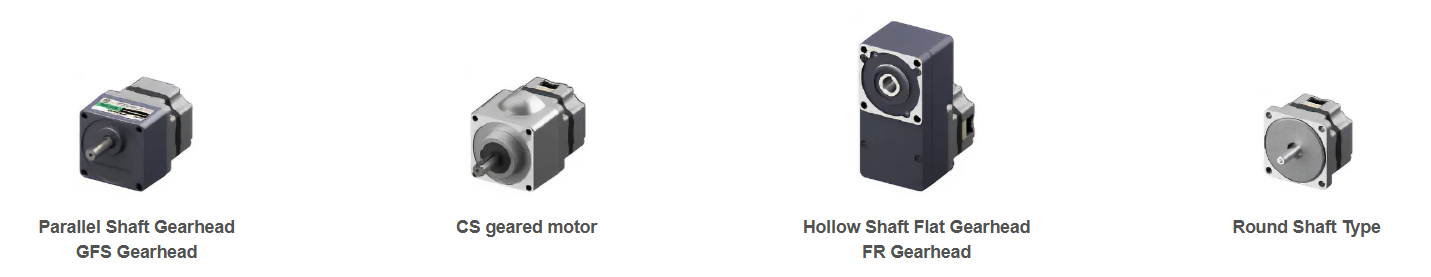

Gearheads Selectable According to the Application

| Gearhead Type | Parallel Shaft Gearhead | Hollow Shaft Flat Gearhead | |

|---|---|---|---|

| GFS Gearhead | CS Geared Motor | FR Gearhead | |

| External View |  |  |  |

| Features | Wide range of gear ratios Rated life of 10000 hours* | Increased load capacity center shaft Rated life of 10000 hours | Space saving, cost saving Unsaturated permissible torque Rated life of 10000 hours |

| Motor Output Power | 15 W/30 W/50 W/100 W | 15 W/30 W/50 W | 30 W/50 W/100 W |

| Gear Ratio | 5~200 | 5~20 | 5~200 |

- *The 15 W unit has a rated life of 5000 hours.

Significantly Increases Permissible Load Flange Drive Adapter (Sold separately)

Mounting on a parallel shaft gearhead increases permissible radial and axial loads.

Support Software Compatible

Useful Functions Utilizing Support Software MEXE02

By using the support software MEXE02, you can set and edit operation data and various parameters, as well as teach and monitor various conditions.

Comprehensive Support From Start-Up to Maintenance With a Variety of Functions

Useful functions for wiring check and test operation are provided.

- Setting and Saving of Operation Data

- I/O Monitor

- Teaching, Remote Operation

Waveform Monitor

Diagnostic and maintenance functions are available for trouble diagnosis and maintenance after operation is started.

- Alarm Monitor

- Status Monitor

- Information Monitor

Batch Configuration and Centralized Management via Network Communication

RS-485 communication can be used to set operation data and parameters, as well as input operation commands. The Modbus (RTU) protocol is used.

Easy to Set and Change Operation Data and Save Wiring

Advantages

- Operation data such as rotation speed and torque limiting value can be easily rewritten.

- Operation data and parameters can be set together for multi-axis.

- Remote I/O and serial communication reduces wiring.

Remote and Ongoing Monitoring Enabled

Advantages

- Continuously monitors the driver status, including rotation speed and load factor.

- The information function enables preventive maintenance and systematic maintenance.