Japan, Orientalmotor

Orientalmotor DRII Series Compact Electric Cylinder, CVD Series Pulse Train Input Type

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: DRII Series, CVD Series

Significantly reduce design man-hours and time

The linear motion mechanism is concentrated in a compact body.

Since parts that were previously prepared by the customer are no longer necessary, the time required for device design and part selection is reduced.

Furthermore, the time required for assembly and adjustment of mounting accuracy can be reduced, contributing to improved production efficiency for customers.

Making the device smaller and lighter

The rotor is hollowed out and the ball screw is housed inside. This

eliminates the need for couplings, ball screw bearings, and other parts that customers have to prepare, making the device more compact and lightweight.

Affordable price

This compact unit contains mechanical components such as ball screws and is available from 51,900 yen.

- Rolled ball screw type: from 51,900 yen

- Precision ball screw type: from 92,000 yen

(The price includes the compact electric cylinder and the driver.)

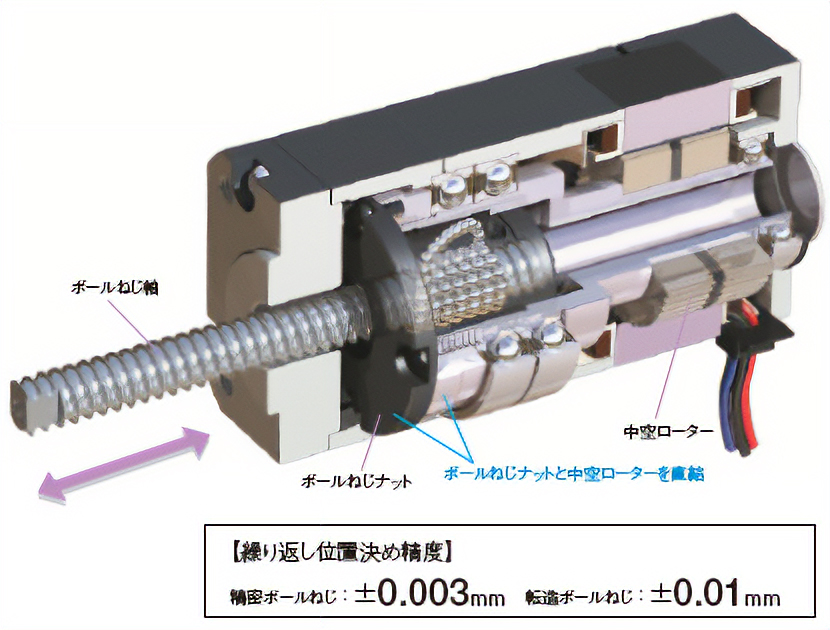

High-precision positioning

Ball screw nut is connected to hollow rotor

The effect of backlash caused by the combination of parts such as coupling rigidity has been reduced, making it possible to achieve highly accurate positioning.

Internal structure

The DRLII series has a hollow rotor structure that allows the ball screw to be stored inside. The ball screw nut rotates as the hollow rotor rotates, and the ball screw shaft moves linearly by providing a rotation prevention mechanism * at the tip of the ball screw . There are two types of ball screws: precision ball screws for minute feed and high-precision positioning, and rolled ball screws that are reliable for general positioning. The ball screw shaft is stored inside the hollow rotor, ensuring maximum stroke with a short overall length. In addition, a large-diameter bearing is placed on the outer periphery of the ball screw nut to directly bear the large axial load generated during linear movement.

- * Guide and table types are not required.

Uses a stepping motor that stops precisely

The DRLII series uses a stepping motor.

Because it is a stepping motor, the positioning accuracy of each step is high, allowing for accurate forward and backward movement.In addition, since there is no hunting phenomenon, in which the axis moves slightly when stopped, the stopped position can be maintained reliably.

Choose from 3 types depending on your needs

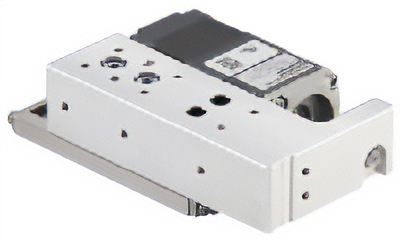

| type | Guide Type | Table type | No guide type |

|---|---|---|---|

| exterior |  |  |  |

| This product is a compact electric cylinder with a guide that can secure a load. It is easy to directly attach a load. | This product is a compact electric cylinder with a guide that can secure a load. It is easy to attach the load and the main body, and allows transportation with a reduced height of the moving part. | This product can be directly incorporated into your equipment or used as a compact thrust shaft in the load transport guide of the equipment. |

Additional features/others

Each type is available with additional features such as an “adjustment knob” and an “electromagnetic brake”. In addition, the DRLM28, DRLM42, and DRLM60 types without guides are available with long strokes.

With adjustment knob

The position can be adjusted manually when the power is off. This is convenient for equipment maintenance, etc.

With electromagnetic brake

The stop position is maintained when the power is turned off.

Even if it is installed vertically, there is no need to worry about the workpiece falling, so you can use it with peace of mind.

Line up

Please purchase the compact electric cylinder, driver, and connection cable separately.

| type | Mounting angle dimensions [mm] | Stroke [mm] | Thrust [N] |

|---|---|---|---|

| Guide Type | 20 | twenty five | 15 |

| 28 | 30 | 30 | |

| 42 | 40 | 30, 100 | |

| 60 | 50 | 300 | |

| Table type | 20 | twenty five | 15 |

| 28 | 30 | 30 | |

| No guide type | 20 | twenty five | 15 |

| 28 | 30, 60 | 30 | |

| 42 | 40, 100 | 30, 100 | |

| 60 | 50, 100 | 300 |