Japan, Orientalmotor

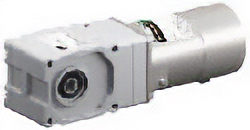

Orientalmotor DSC Series AC Speed Control Motors

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: DSC Series

Overview of DSC Series

Speed Control Using Closed Loop Control

Speed Regulation ±1 % (Reference value)

The tachogenerator built into the AC motor continuously monitors the rotation speed. The system actively controls the actual speed to match the speed setting, ensuring stability even when the load fluctuates.The system continuously adjusts the actual speed to match the speed setting, maintaining consistency even when the load changes.

Digitalization of Circuits

In the past, most analog circuits transitioned to digital, now managed by the CPU, significantly reducing circuit components. This shift has led to unprecedented miniaturization and lower costs.. In addition, digitization has made it possible to keep the deviation between the speed command value and the speed detection value close to zero, and the speed regulation has been improved from -5 % to ±1 %*.

*Change the torque value from 0 N·m to permissible torque (at 1000 r/min)

Easy Setting, Less Space

Compact

The volume is 63 % smaller than a general inverter.

Side-by-Side Installation Saves Space

The body width is 35 mm, and even when using multiple axes, the installation is compact because they can be installed side by side.

Slim Body Control Cabinet

With a depth of 90 mm, it fits into slim body control cabinets.

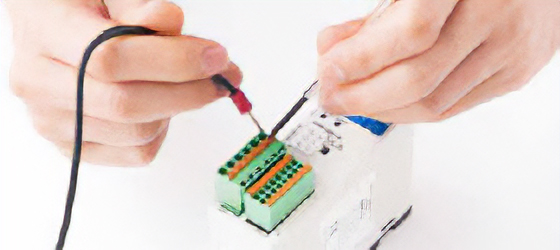

One-Touch Operation of Connector Connection between Motor and Driver

Wiring the speed controller and motor together uses a connector, for easy installation and removal.

Wiring for I/O and other connections uses a screwless method, eliminating the need for crimping or screwing.

No need for soldering or crimping tools, and no tightening torque management for screws necessary. Reduces wiring time and maintenance.

Easy Installation to DIN Rail

Install the speed controller directly on the DIN rail.

High Reliability

Low Noise Gives Peace of Mind, and System Configuration is Simple

Alarm Output Increases Reliability

Thanks to the closed loop control, the controller receives real-time feedback on the motor status. The system outputs an alarm signal when an abnormality, such as motor lock due to overload, occurs and stops the power supply to the motor.

Vertical Operation is Possible With Electromagnetic Brake Type

Speed control in vertical operation is possible through deceleration control.

Ample Functionality in a Compact Body

The display shows speed and other settings, allowing direct entry.

Test operation behavior

Speed Control (4 speeds)

Set 4 units of operation data and switch them with I/O during operation.

Acceleration/Deceleration

Makes the motor movement at start/stop smoother.

It is possible to set acceleration/deceleration differently for each of the 4-speed data units.

Bi-Directional Operation

Performs the operation according to the command for rotation direction.

Instantaneous Stop

Stops the operating motor instantaneously.

(Create short cycle run/stop conditions.)

Instantaneous Bi-Directional Operation

Instantaneously switches the rotation direction of the motor while operating.

(Create conditions for short cycle changes.)

External Speed Setting is Available

Set using the operation keys, an external speed potentiometer (sold separately), or external current voltage.

Multi-Motor Control (20 units max.)

A single external speed potentiometer can operate a max. of 20 units in parallel.

Adjust each motor’s speed by changing the controller’s parameters.

Speed Range Control

It is possible to limit the speed setting in advance with the speed range.

High Strength Gears are Used for Both Right-Angle and Parallel Shafts

Use of a High Permissible Torque, High Strength Gearhead

Uses a motor and gearhead that excels in both permissible torque and strength.

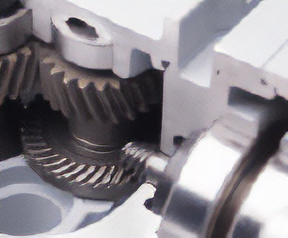

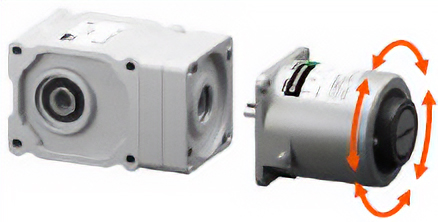

Right-Angle Hollow Shaft Hypoid JH Gearhead

High strength hypoid gears are used. Significant torque enhancement and noise reduction compared to conventional products are achieved.

The radial and axial loads on the gearhead output shaft are also greatly increased, contributing to the downsizing and enhanced reliability of the equipment.

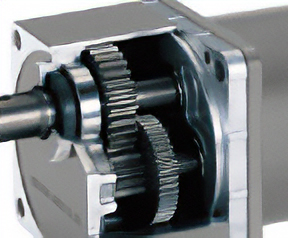

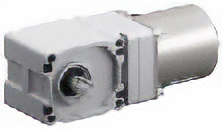

Parallel Shaft Gearhead GV Gearhead

By increasing the size of the output shaft bearing and using carburized gears, the permissible torque and permissible radial and axial loads have been increased compared to the conventional gearhead.

Motor and Gearhead Preassembled (Right-angle hypoid JH/JL gearhead, parallel shaft gearhead GV gearhead)

The motor and gearhead are delivered pre-assembled

This allows customers to reduce assembly time and install it in equipment right away.

The Gearhead Can be Removed

The motor position can be rotated by 90˚ to change the direction of the lead wire extraction. In addition, the gearhead only can be purchased to change the gear ratio or replace during maintenance.

Space Saving and Cost Reduction

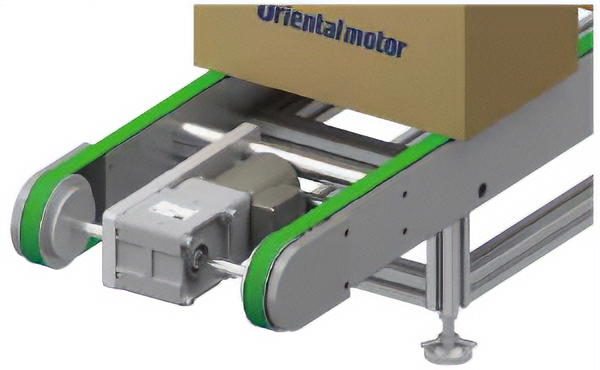

Right-Angle Hollow Shaft Hypoid JH Gearhead/Right-Angle Solid Shaft Hypoid JL Gearhead

Motor Mounted Perpendicularly to Drive Shaft for Space Saving

Cost Reduction by Directly Linking to the Drive Shaft

Installation Inside the Conveyor Saves Even More Space

Conveyor drive rollers can be installed on both ends of the load shaft of a hollow shaft type.

The equipment can be made even smaller compared to when the motor is installed on the side of the conveyor.

Easy Installation With Torque Arm

The torque arm (sold separately) further reduces installation time and effort. (Hollow shaft type)

- Easily centered with the equipment

- Only one needed to stop rotation and secure the equipment

Product Line

The “motor,” “speed controller,” and “connection cable” are arranged separately. They can be purchased in various combinations.

(When the screen transitions upon selecting motor type, the names of the motor, speed controller, and connection cable, each associated with a “+,” will be displayed as a candidate.)

Parallel Shaft Gearhead GV Gearhead and Round Shaft Type

| Combination Motor | Voltage [V] | Upper Row: Motor Frame Size/Lower Row: Output Power | ||||||

|---|---|---|---|---|---|---|---|---|

| 60 mm | 70 mm | 80 mm | 90 mm | |||||

| 6 W | 15 W | 25 W | 40 W | 60 W | 90 W | |||

| Standard Type Parallel Shaft Gearhead GV Gearhead | Single-Phase 100, 110/115, 200, 220/230 | ● | ● | ● | ● | ● | ● |

| Standard Type Round Shaft Type | |||||||

| Electromagnetic Brake Type Parallel Shaft Gearhead GV Gearhead | |||||||

Right-Angle Hypoid Gearheads

| Combination Motor | Voltage [V] | Upper Row: Motor Frame Size/Lower Row: Output Power | ||||||

|---|---|---|---|---|---|---|---|---|

| 60 mm | 70 mm | 80 mm | 90 mm | |||||

| 6 W | 15 W | 25 W | 40 W | 60 W | 90 W | |||

| Standard Type Right-angle hollow shaft hypoid JH Gearhead | Single-Phase 100, 110/115, 200, 220/230 | – | – | ● | ● | – | ● |

| Standard Type Right-angle solid shaft hypoid JL Gearhead | |||||||

| Electromagnetic Brake Type Right-angle hollow shaft hypoid JH gearhead | |||||||

| Electromagnetic Brake Type Right-angle solid shaft hypoid JL gearhead | |||||||