Japan, Orientalmotor

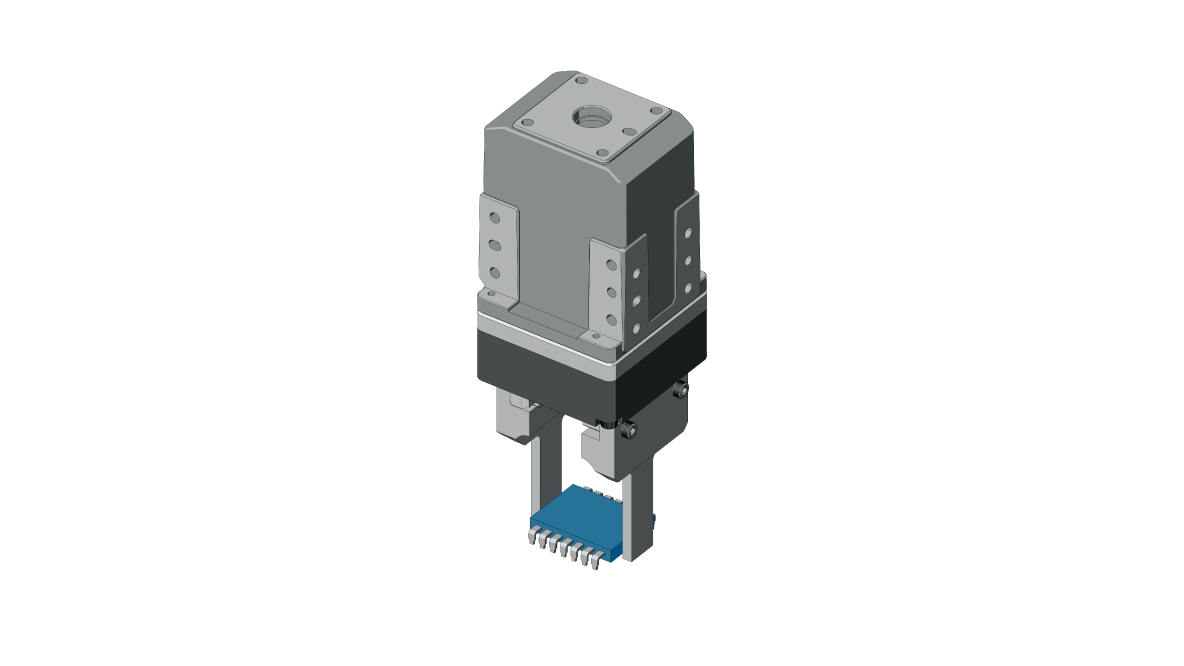

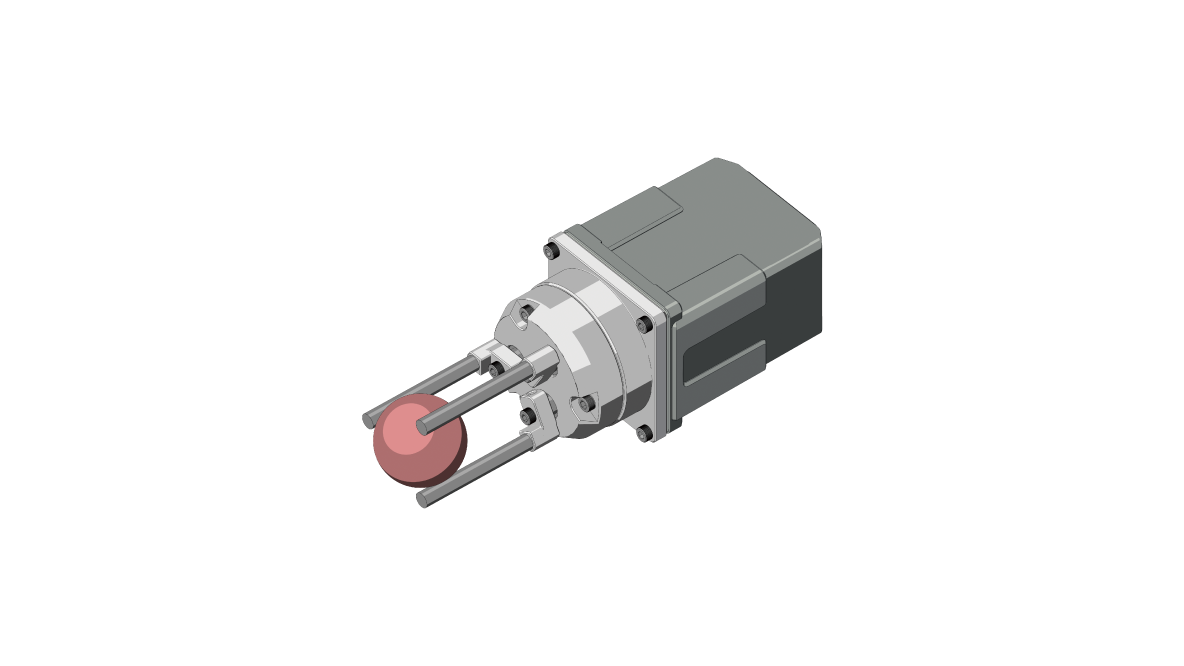

Orientalmotor EH Series Electric Grippers

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: EH Series

Key Features

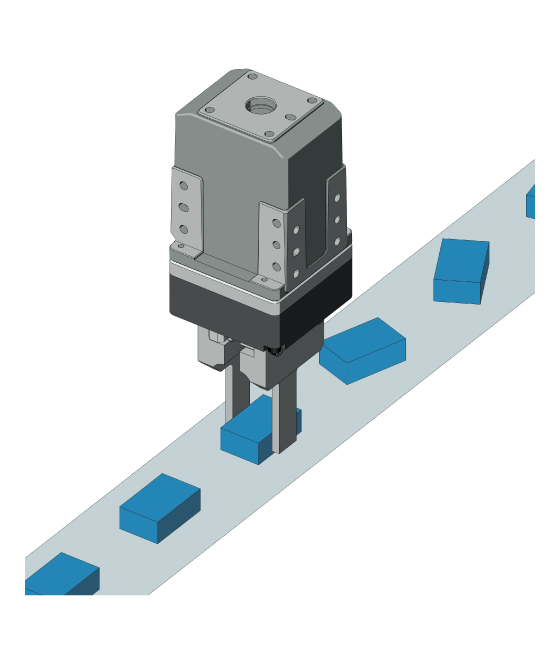

A “Delicate Grip” Approach to a Wide Variety of Load

The operating current can be set in 1 % increments, allows fine-tuning the gripping force.

Grasp

Easy-to-damage and easy-to-deform loads can be gripped.

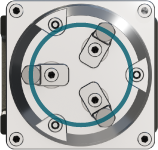

The 3-finger type is suitable for gripping spherical, cylindrical or easily deformable loads.

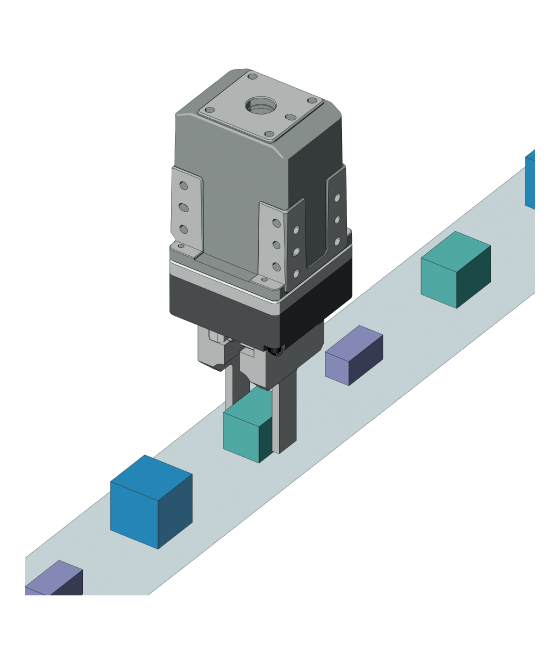

Align

Loads can be oriented and aligned.

Measure

Load size can be determined and measured.

For Delicate Operations, the EH Series is Recommended Over a Pneumatic Gripper

Adjust the Gripping Force in 1 % Increments (2-Finger and 3-Finger)

Adjustment with a pneumatic gripper’s regulator (pressure reducing valve) is unnecessary. The gripping force can be easily and finely adjusted with digital settings.

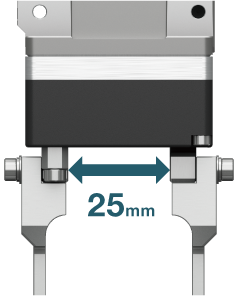

Adjust the Speed in 0.02 mm/s Increments (2-Finger)

Adjustment with a pneumatic gripper’s speed controller (speed control valve) is unnecessary.

Adjust the Traveling Amount in 0.02 mm Increments (2-Finger)

This gripper takes advantage of the high positioning accuracy of the stepper motor.

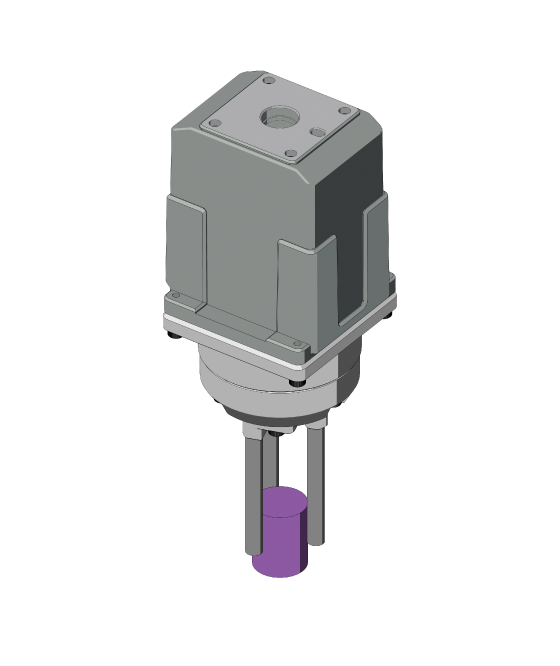

Position Monitoring With an ABZO Sensor (2-Finger and 3-Finger)

Detailed position information can be monitored. When using the 2-finger type, position information can also be used to determine the load size.

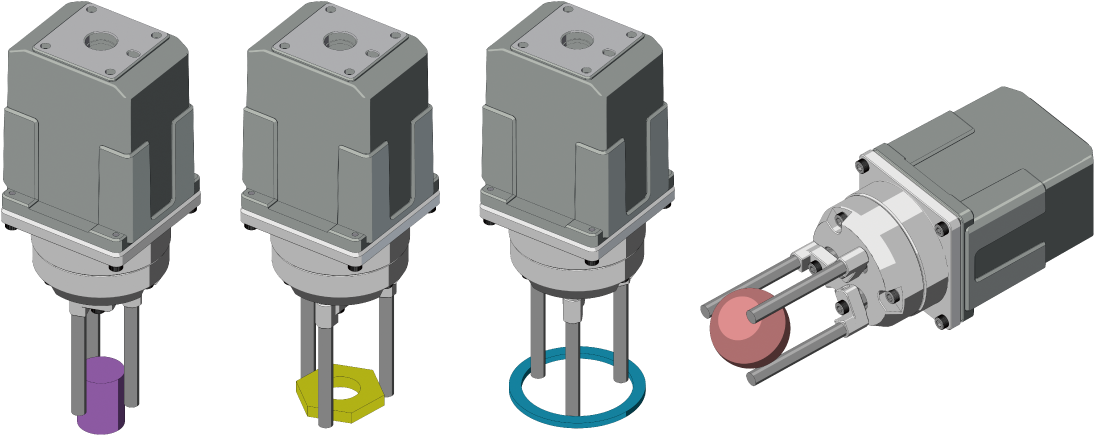

2-Finger Type and 3-Finger Type Can be Used for Different Applications

Comparison of 2-Finger and 3-Finger Types

| Type | 2-Finger*1 | 3-Finger | ||

|---|---|---|---|---|

| Load Shape Suitable for Gripping |  |  | ||

| Moving Range |  |  |  | |

| When Open: P.C.D. ϕ30.9 mm | When Closed: P.C.D. ϕ7 mm | |||

|  | |||

| Opening Width: P.C.D. ϕ23.9 mm | ||||

| Max. Gripping Force [N] | 25 | 50 | ||

| Permissible Load [N] (Permissible axial load [N]*2) | 5 | 15 | ||

| Mass [kg] | 0.38 | 0.38 (with mounting cover) 0.28 (without mounting cover) | ||

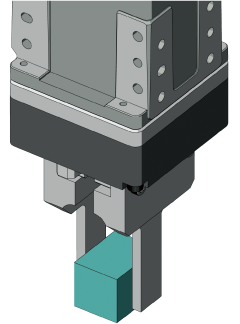

Features of 3-Finger Type

Due to the large permissible axial load, it is suitable for application with large load masses.

Each finger opens and closes while rotating.

Advantages of AZ Series Equipped

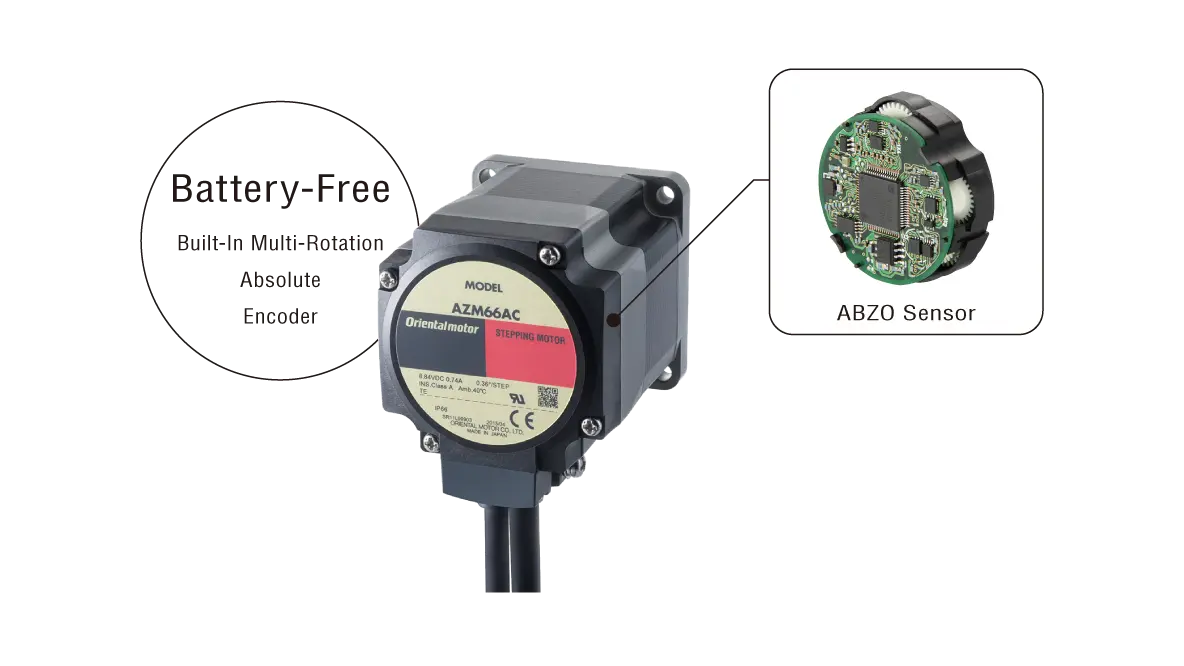

Battery-Free Absolute Encoder Equipped

It is equipped with a small battery-free mechanical absolute encoder (ABZO sensor). This can help improve productivity and reduce costs.

- Mechanical-Type Sensor

Retains positioning information even when power is not supplied - Multi-Rotation Absolute Encoder

Absolute position detection is possible with ±900 (1,800) revolutions of the motor shaft from the home position

No External Sensors Required

As it is an absolute system, home sensors or limit sensors are not required.

Advantages

- Improved High-Speed Return-to-Home + Return-to-Home Accuracy

- Reduced Cost

- Simple Wiring

- Not Affected by External Sensor Malfunction

Battery-Free

Mechanical sensors do not require batteries.

Positioning information is managed mechanically by the ABZO Sensor.

Advantages

- No need to replace batteries

- Unlimited Driver Installation Possibilities

- Safe for Overseas Shipping

Simplifying the Main Program via Sequence Function

The AZ Series come equipped with a wide variety of sequence functions such as timer settings for linked operation and during operations, conditional branching, and loop operation. (excluding some models)

It can be set up using the support software MEXE02, which simplifies the sequence program of the host system.

- Positioning Operation Data Setting Value (max. 256)

- General-Purpose I/O Signal Counts (Input 10, Output 6)

- Communication I/O Signal Counts (Input 16, Output 16)

AZ Series-Equipped Product Line

Since the motors installed are the same, the operating and maintenance methods are the same.

Electric Actuators (AZ Series equipped)

| Electric Linear Slides | Electric Cylinders | Compact Electric Cylinders | Rack-and-Pinion System | Electric Grippers | Hollow Rotary Actuators |

|---|---|---|---|---|---|

| EAS Series EZS Series EZSH Series | EAC Series | DR Series DRS2 Series | L Series LJ Linear Heads Combination With AZ Series* | EH Series | DGII Series |

- The power supply input of the installed motor differs between Series. Please refer to each series page for the detailed product line.

*For the LJ linear head, the AZ Series is purchased separately and assembled for use.

Driver Features and Product Line

The lineup is available for a variety of controls, systems, and interfaces.

| Driver Type | Compatible Interfaces | Single Axis Driver | |

|---|---|---|---|

| DC Input | |||

| |||

| Network Compatible | Drivers are controlled directly from a host control device through industrial network | EtherCAT | ○ |

| EtherNet/IP™ | ○ | ||

| PROFINET | ○ | ||

| MECHATROLINK-Ⅲ | − | ||

| SSCNETⅢ/H | − | ||

| Built-in Controller | Operation data is built into the driver. Controllable by Modbus (RTU) and I/O. Can be controlled via CC-Link by using a network converter. | Modbus (RTU) I/O CC-Link* | ○ |

| Pulse Input with RS-485 Communication | Controlled by pulse signal. Motor status information can be monitored via Modbus (RTU). | Pulse inputModbus (RTU) | ○ |

| Pulse Input | Controlled by pulse signal | Pulse input | ○ |

- *EtherCAT® is registered trademark and patented technology, licensed by Beckhoff Automation GmbH, Germany.

- *EtherNet/IP™ is a trademark of ODVA.

- *PROFINET is a trademark or registered trademark of PROFIBUS Nutzerorganisation e.V. (PNO).

- *MECHATROLINK is a registered trademark of the MECHATROLINK Members Association.

- *SSCNETⅢ/H is a registered trademark of Mitsubishi Electric Corporation.

- *CC-Link is a registered trademark of the CC-Link Partner Association.