Japan, Orientalmotor

Orientalmotor EZS Series Electric Linear Slides

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: EZS Series

High Rigidity and High Accuracy

Even with the compact motor, a high permissible moment is possible due to the high rigidity of the guide.

High Rigidity, High Accuracy Guide

The guides used on linear slides are LM Guide* made by THK.

The flat stainless steel guide can tolerate high moments.

- *Registered trademark of THK Co., Ltd.

Slim Body With Large Transportable Mass

High Permissible Moment

A high load moment is achieved from a compact body.

- *In the case of EZSM6.

Permissible Moment Value in Rolling Direction [N·m]

| Model | Static Permissible Moment | Dynamic Permissible Moment |

|---|---|---|

| EZSM3 | 52.0 | 10.5 |

| EZSM4 | 176 | 27.8 |

| EZSM6 | 340 | 55.6 |

Capable of Driving Heavy Loads at High Speeds

Can be Installed Even in Small Spaces

This product structure is also suitable when space is limited.

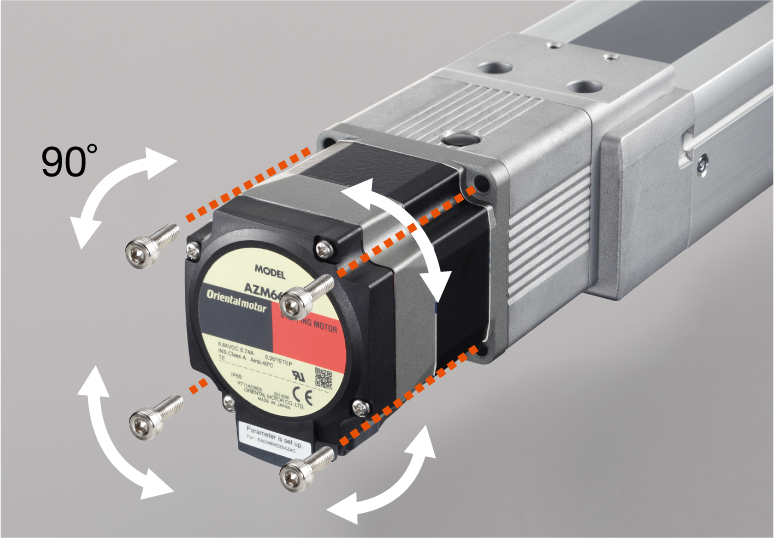

Avoidance of Interference With Peripheral Equipment

The mounting direction of the motor can be changed in 4 directions, allowing the cable outlet direction to be freely changed to suit the installation location.

Reversed Motor Type to Shorten Overall Length

The length of the reversed motor type is up to 136.4 mm shorter than the straight type. This contributes to space saving with equipment.

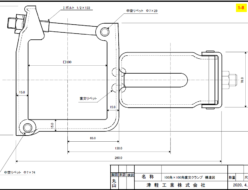

Simple Dust-Resistant Structure

The simple dust-resistant structure made from a stainless steel sheet prevents ingress of foreign particles and reduces emission of dust.

Keeps Out Foreign Particles

Simple dust-resistant structure with stainless steel sheet prevents intrusion of foreign particles.

Dust Preventing Structure

The low dust-generative roller structure in the table part rotates against the stainless steel sheet to prevent the generation of particles via friction.

For Clean Room Use (ISO Standards Cleanliness Class 3)

In addition to the low dust-generative roller structure, some products for clean room use achieve the cleanliness class of ISO Standards Class 3 (equivalent to FED Standard Class 1) through the use of low dust-generative clean grease.

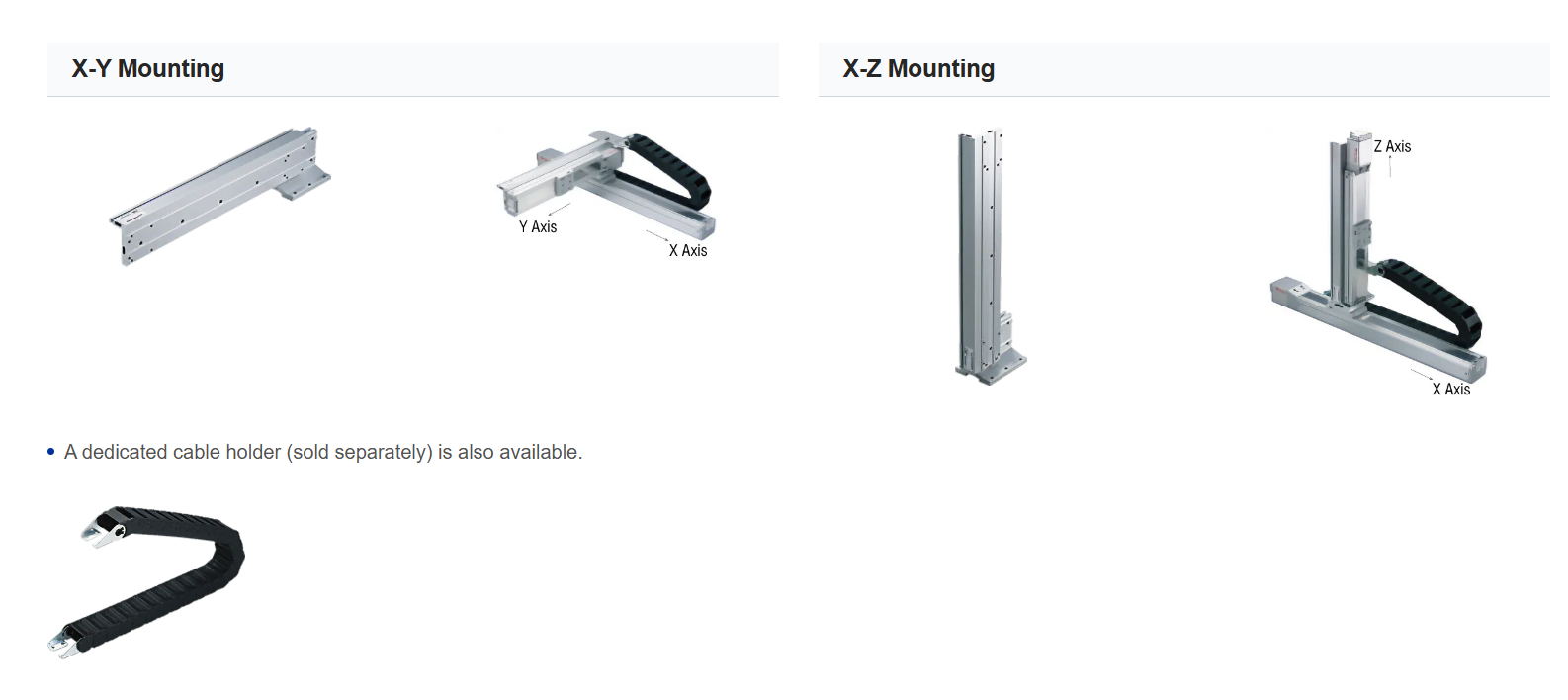

Easy Combination of 2 Axes

Dedicated mounting bracket for easy combination of 2 axes.

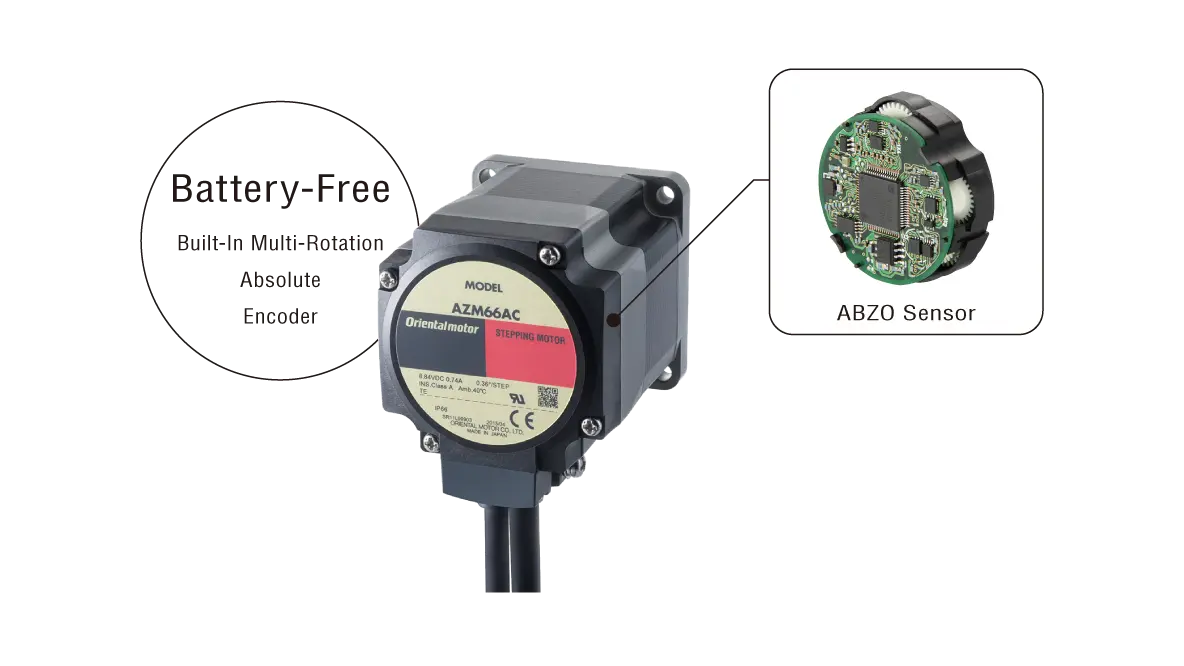

Battery-Free Absolute Encoder Equipped

It is equipped with a small battery-free mechanical absolute encoder (ABZO sensor). This can help improve productivity and reduce costs.

- Mechanical-Type Sensor

Retains positioning information even when power is not supplied - Multi-Rotation Absolute Encoder

Absolute position detection is possible with ±900 (1,800) revolutions of the motor shaft from the home position

No External Sensors Required

As it is an absolute system, home sensors or limit sensors are not required.

Advantages

- Improved High-Speed Return-to-Home + Return-to-Home Accuracy

- Reduced Cost

- Simple Wiring

- Not Affected by External Sensor Malfunction

Battery-Free

Mechanical sensors do not require batteries.

Positioning information is managed mechanically by the ABZO Sensor.

Advantages

- No need to replace batteries

- Unlimited Driver Installation Possibilities

- Safe for Overseas Shipping

Simplifying the Main Program via Sequence Function

The AZ Series come equipped with a wide variety of sequence functions such as timer settings for linked operation and during operations, conditional branching, and loop operation. (excluding some models)

It can be set up using the support software MEXE02, which simplifies the sequence program of the host system.

- Positioning Operation Data Setting Value (max. 256)

- General-Purpose I/O Signal Counts (Input 10, Output 6)

- Communication I/O Signal Counts (Input 16, Output 16)

Data Collection of Motor Operation Status and Functions Useful for Preventive and Predictive Maintenance

This software is equipped with various monitoring functions for checking the operating status of the motor.

By using different monitors for different situations, it is possible to shorten the start-up and adjustment time of the equipment, as well as to utilize it for maintenance and servicing.

Monitoring Function to Visualize the Motor Operating Status and Help Collect Data

The ABZO sensor bulit in the AZ Series allows you to monitor the motor’s operating status numerically.

[Monitoring With MEXE02 Support Software]

In addition, the built-in controller type can realize data collection at a host master via industrial network.

Information Functions Useful for Preventive and Predictive Maintenance

By setting arbitrary numerical values for the monitored information items, external signals can be output when the values are reached.

Importing this information into the host controller helps in early detection of problems and adjustment of product maintenance timing.

Examples of Information Functions

TRIP Information

You can set the number of rotations you want to output in advance, and output when that number is reached. (Motor operation will continue)

Temperature Information

You can set the desired output temperature in advance, and the driver will output when it reaches that temperature. (Motor operation will continue)

Standardized Wiring, Control, and Maintenance Parts

Various actuator products equipped with the αSTEP AZ Series are available.

They each have the same motor and driver, which allows for standardized wiring, control, and maintenance parts.

Wiring Standardization

The wiring for motor cables, I/O signals, and power supply is the same.

Control Standardization

These products can be operated via the same method, since the control method is the same. For the network control, the remote I/O and the command code are also the same. It saves you the trouble of creating a program.

Unification of Maintenance Parts

Maintenance parts can be minimized, since the motor, driver, and cable are common to all. Management costs (parts cost, management space) can be reduced.