Japan, Orientalmotor

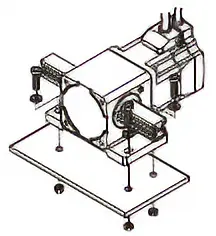

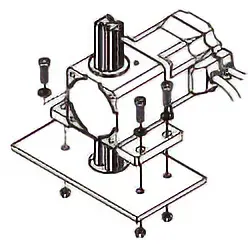

Orientalmotor L Series αSTEP AZ Series Equipped Rack-and-Pinion System

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: L Series

Compact Size and Maximum Transportable Mass of 100 kg

Maximum Transportable Mass 100 kg

Larger-diameter pinion with increased gear strength realizes a maximum transportable mass of 100 kg

Maximum Stroke 1000 mm

Product line includes strokes from 100~1000 mm

Comparison With Electric Linear Slide

The rack-and-pinion system can transport the transportable mass if it is mounted without consideration of the moment of inertia.

Overview of Rack-and-Pinion System

The rack-and-pinion system can easily convert the rotation of the motor into linear motion.

Although the linear motion mechanism part is compact in design, it can transport a large load due to its high strength processing.

Contributing to Design Efficiency

Reduces Startup Time

The rack-and-pinion system reduces the number of components traditionally used, significantly reducing the man-hours required for design and assembly.

Space Saving

By fixing the screw holes on both ends of the rack, the main unit can be self-propelled. This function is effective for equipment that is too small to provide motor space.

Allows Setting in mm Units

αSTEP AZ Series is used for the drive motor.

Using together with the MEXE02 support software makes setting travel amount in mm units easy, allowing for a variety of linear motion applications.

Minimum Travel Amount

| High-Speed Type | Large Transportable Mass Type |

|---|---|

| 0.01 mm | 0.001 mm |

Operating Speed Range (For AC input type)

| High-Speed Type | Large Transportable Mass Type | |

|---|---|---|

| Frame Size 60 mm | Frame Size 80 mm | |

| 0~500 mm/s | 0~90 mm/s | 0~40 mm/s |

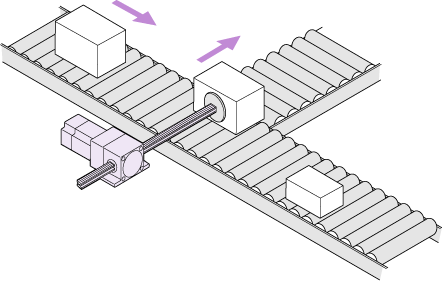

Applications

The rack-and-pinion system, which can be applied to a variety of applications, is a user-friendly product that can be selected as if it were a component.

| Rack Moving Direction | Motor Fixed | Rack Fixed |

|---|---|---|

Parallel (B type) |  Easily move objects by pushing or pulling. |  A wide variety of stroke and speed is available. |

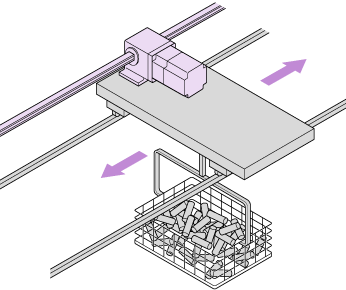

Vertical (F type) |  Vertical operation is also easy. Electromagnetic brake drop protection is also available. |  Using the screw holes at the end of rack simplifies the fastening of loads and rack fixing. |

Real examples from the Oriental Motor production facilities of load elevating and lowering equipment used to explain points for adoption of products.

Oriental Motor’s extensive product lineup and wide range of services contribute to overall reduced costs, by shortening startup times, and equipment design with specifications to meet your needs.

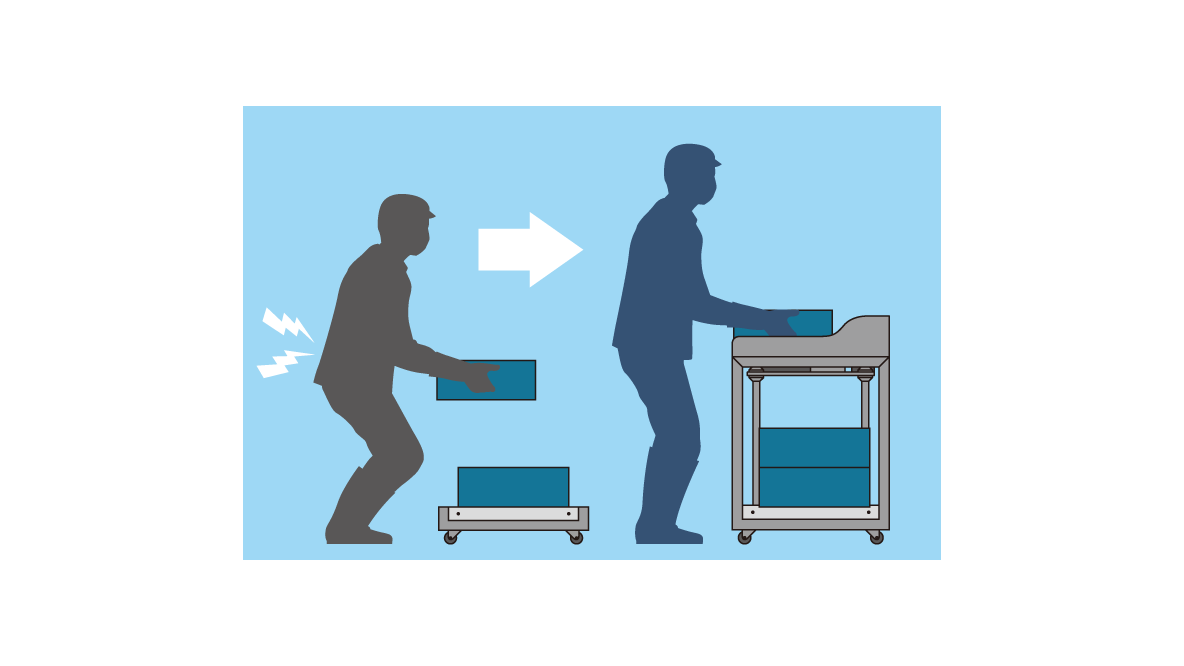

Labor-Saving Ideas

At Japan’s Manufacturing sites, labor shortages due to a decline in the working population associated with the decreasing birthrate and aging population is becoming an issue. Amidst this, there is an urgent need for labor-saving that reduces the burden of “heavy lifting work” and “repetitive work such as sorting.” Rack-and-pinion system that transports high loads contributing to labor-saving in manufacturing operations.

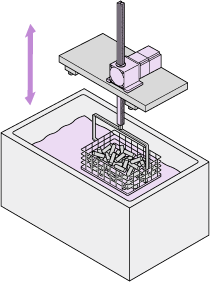

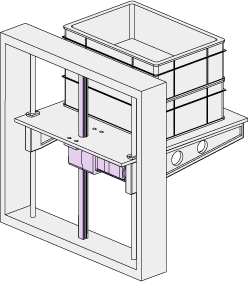

Loading and unloading of buckets, which places a burden on the body. Automatic lifting equipment using a rack-and-pinion system can reduce the burden on the operator.

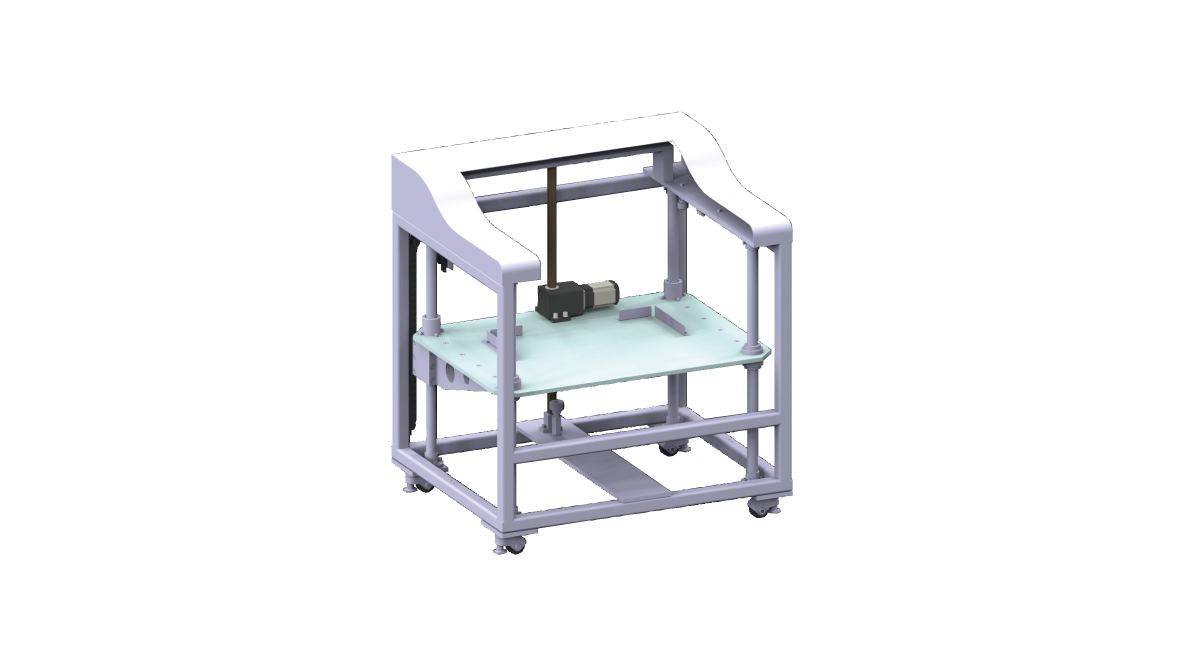

Loading and unloading of buckets, which places a burden on the body. Automatic lifting equipment using a rack-and-pinion system can reduce the burden on the operator.Use Example for L Series (Automated lifting equipment demonstration unit)

Oriental Motor offers a demonstration unit (for exhibition) of the automatic lifting equipment using the L Series. With a simple mechanism, heavy objects up to 100 kg can be lifted and lowered. Refer to the video for details on lifting equipment.

Transportable Mass: 100 kg (at 20 mm/s)

Stroke: 600 mm

Rack-and-Pinion System Labor-Saving Recommendations

| Product Name | List Price | ||

|---|---|---|---|

| L Series F Type |  | LM4F40AZMC-6 | 106,500 JPY |

| Built-In Controller Type Driver | AZD-AD | 57,200 JPY | |

| Flexible Connection Cable Set (2 m) |  | CC020VZRB | 11,800 JPY |

Related Products

-

SENSEZ CXV.CXI Connector-type Pressure Sensors

-

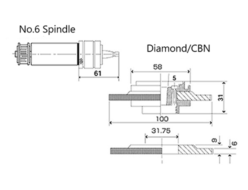

UHT Corporation Diamond Grinding Wheels for Spindle No.6 #200

-

Kansai Electric Heat Corp H-Type Series T.S.K Hot-air Generator

-

SAKUSAKU 4SS-30D 9.0S Carbide Square End Mill 4-Flute

-

Kitz AKTAFM Type 600 Brass Ball Valves (Full Bore)

-

NAC – AL TYPE 20 Stainless steel (SUS304) PH (Hose nipple)