Japan, Orientalmotor

Orientalmotor LH Linear Heads (Speed control motors)

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: LH

Features of the Linear Head

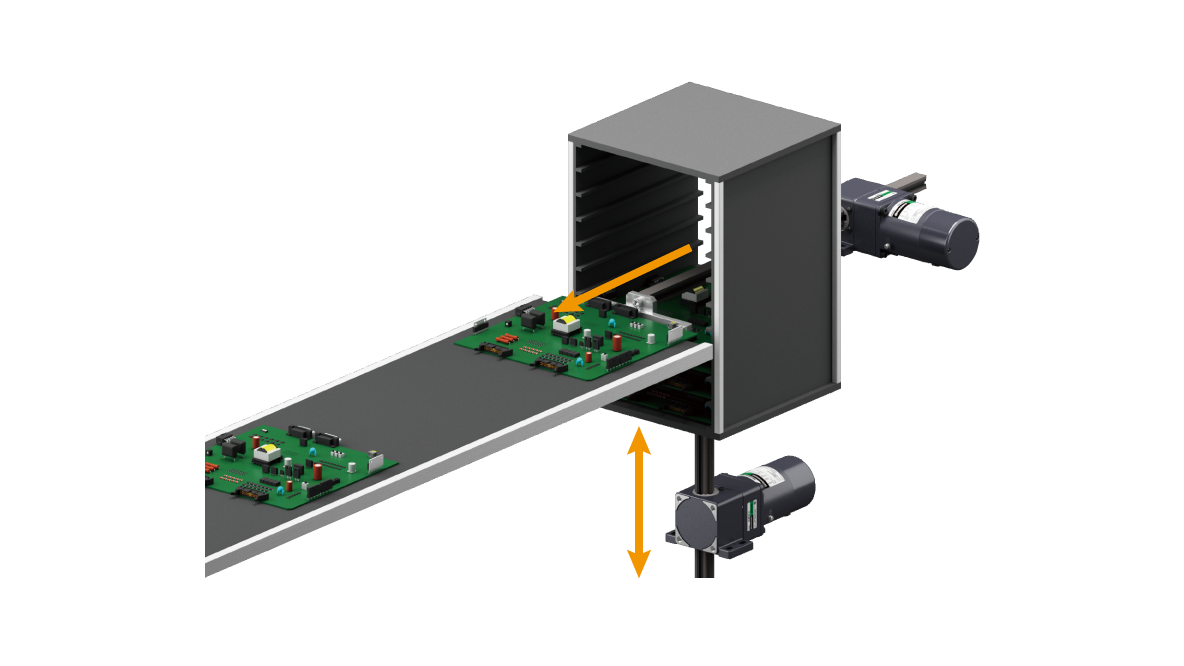

The motor can integrate with a rack-and-pinion mechanism to provide linear motion for pushing, pulling, raising, and lowering.

| LH Linear Heads | |

|---|---|

| Maximum Transportable Mass | ~140 kg |

| Stroke | 100~700 mm |

| Operating Speed | 10 mm/s |

| Combination Motor | AC speed control motors (MSD Series) |

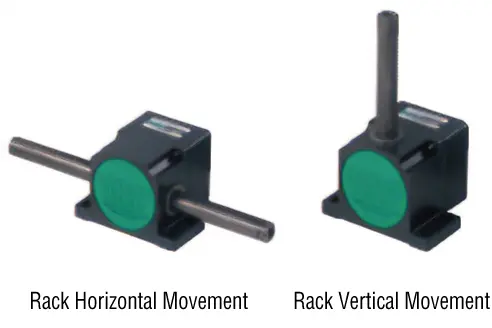

| Linear Head Shape (Rack moving direction) | 2 types available |

| Motor Assembly Method | Assemble motor  |

Contributes to Improved Design Efficiency

Reduces Startup Time From Design

Compared to building the rack-and-pinion mechanism on your own, the number of parts used and the labor required for design and assembly can be reduced.

Fix the Rack to Make the Best Use of Space

The motor can run by itself by fixing both ends of the rack.

Effective when it is difficult to find motor space.

Applications

The rack-and-pinion mechanism is easy-to-use and can be incorporated as a component.

*When the rack is used in the vertical direction, the speed cannot be controlled by the down side drive. Use at full speed.

Product Line

Please purchase the linear head and motor separately.

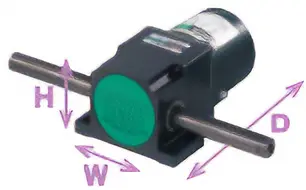

| Linear Head Product Line (Combined motor output power: W) | W × H × D [mm] | Maximum Transportable Mass kg* (Variable speed range mm/s*) | Stroke [mm] | |||

|---|---|---|---|---|---|---|

| LH Linear Heads | 2L (6) | 88 × 66.3 × 164.5 | 8.7 (3.2~57) | 15 (1.6~28) | 20 (0.7~12) | 100, 200, 300, 400, 500 |

| 4L (25) | 120 × 82 × 191 | 27 (2.8~50) | 52 (1.3~24) | 70 (0.7~12) | 100, 200, 300, 400, 500, 600, 700 | |

| 5L-U (60) | 140 × 95 × 270.5 | 57 (3.1~56) | 127 (1.3~22) | 140 (0.6~11) | 100, 200, 300, 400, 500, 600, 700 | |

*For power supply frequency 60 Hz