Japan, Orientalmotor

Orientalmotor MD Series DC Axial Flow Fans

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: MD Series

Detecting a Fan Abnormality

Agenda

- Fan cooling function had deteriorated before being noticed.

- How do I prevent damage to precision equipment caused by heat generated?

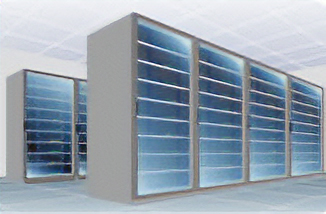

Example) Data center

Fan A type with alarm

Advantages of Fan With Alarm

Alarm output from the fan helps prevent equipment issues and failures in the event of an emergency.

Choose between 2 alarm product lines.

Stall Alarm

Notification When Fan Stops

Alarm signal outputs when fan rotation stops. Stops due to abnormalities can be quickly detected, allowing for the problem fan to be replaced.

Low-Speed Alarm

Notification When Fan Rotation Has Deteriorated

An alarm signal is output when the rotation speed of the fan deteriorates due to ingress of foreign particles, etc.

Contributes to predictive maintenance of equipment issues by allowing fan to be replaced prior to heat damage to equipment.

Even in multi-fan installations, just fans with a deteriorated cooling capacity can be replaced.

Reducing the Number of Maintenance Services

Agenda

- Reducing the number of maintenance services as much as possible

- Equipment must be installed where maintenance is difficult.

Example) Base station

Long life fan E type

Advantages of Long Life Fan

With an expected life of up to 180,000 hours, providing not only cooling performance but also a tough long life performance capable of withstanding continuous duty for about 20 years. It contributes to lower equipment maintenance costs and overall costs.

Expected life varies depending on product. Check product page for details.

Lower Maintenance Costs and Overall Costs

Long life fan significantly reduces the number of fan replacements compared to S Type, reducing total costs.

Lifetime Comparison Example

*Estimated life is 40,000 hours at an ambient temperature of 60 °C. The estimated life is an estimated value calculated using the formula for the life of the bearing grease. The estimated life varies depending on the product.

[Expected Life]

This indicates that 90 % min. of the total number of fans satisfy the following criteria when an acceleration test is conducted at an operating ambient temperature of 60 °C.

Criteria:

Rotation Speed (at rated voltage): 70 % min. of rated value

Input Current (at rated voltage): 130 % max. of rated value

Ideal equipment for where high reliability is required.

Since it is a long life fan that is not prone to failure, it is suitable for systems and equipment that have a significant ripple effect should a failure occur, and for applications that require continuous operation.

[Example applications]

- Backup Equipment for Blackouts

- Various Equipment Installed at Locations Such as Data Centers

- Continuous Operation of Plant Equipment

Stall Alarm

Alarm signal outputs when fan rotation stops.

Cooling While Adjusting the Air Flow

Agenda

- Cooling while adjusting air flow and static pressure due to changes in heat source

- How do I suppress noise?

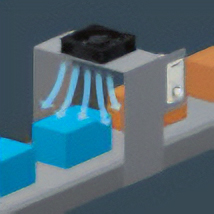

Example) Conveyor cooling

Variable speed fan V type

Advantages of Variable Speed Fans

Fan rotation speed can be adjusted via PWM control.

Air flow and static pressure can be adjusted, yielding energy savings and noise reduction.

Energy Savings, Noise Reduction

When required, driving the fan at the required air flow achieves a reduction in wasted power and noise.

Pulse sensor Output for Constant Monitoring

A signal of 2 pulses per revolution is output while the fan is being driven. By checking for changes in pulse signals, the status of the fan can be constantly monitored. Also ideal for equipment that needs to run 24 hours a day.

- Easy adjustment of air flow with a simple turn of the setting dial

- heck fan air flow and alarms showing abnormalities on the display

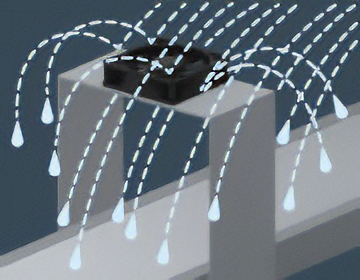

Using in a Location Where Water or Dust is Present

Agenda

I want to use with confidence even in an environment where water or dust is present.

Example) Cleaning equipment

Watertight fan P type

Advantages of Watertight Fan

Watertight type fan that can be used in places where water and dust are present.

Conforms to degree of protection IP68 under IEC Standards.

Degree of protection IP68

[Waterproof test conditions]

Submerged for 60 minutes under no current into water pressurized to a depth equivalent to 2 m.

Then, after operating for 15 minutes in air, no abnormality should be observed in the dielectric strength test.

Stall Alarm

Alarm signal outputs when fan rotation stops.

- Cannot be used under water.

- The IP indication that shows the watertight and dust-resistant performance are specified under IEC 60529 and IEC 60034-5.

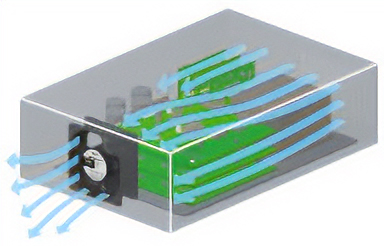

Properly Cooling High-Density Packaging Equipment

Agenda

- Increasing the cooling efficiency

- The number of devices in the control cabinet has increased, and the pressure loss has increased

Example) Control cabinet for high-density packaging

Large fan

Advantages of Large Fan

When pressure loss inside equipment is large, using a large fan is more effective in saving energy and wiring than using several small fans.

For high-speed specifications, the air flow and static pressure are increased without changing the frame size (S type)

The S type is available in “standard speed specification” and “high-speed specification” with up to twice the air flow.

Even when the number of devices in the control cabinet increases and the pressure loss becomes large, the air flow and static pressure can be increased without changing the fan frame size, by replacing it with a high-speed specification.

I Want to Operate Only When Necessary to Reduce Power Consumption and Noise

A “thermostat for fan” is available to automatically control fan operation and shutdown according to temperature changes in the equipment. Fan power consumption and noise can be reduced by running the fan only when necessary.

Select from Frame Size

| Frame Size [mm] | □40 | □52 | □60, 62 | □80 | □92 | □119, 120 | □140 | φ172 | |

|---|---|---|---|---|---|---|---|---|---|

| Thickness [mm] | 20 | 15 | 25 | 25 | 25 | 25 | 38 | 51 | 51 |

| S Type (No alarm) | ● | ● | ● | ● | ● | ● | ● | ● | ● |

| A Type (With alarm) | ● | ● | ● | ● | ● | ● | ● | ● | – |

| E Type (Long life) | – | – | ● | ● | ● | ● | ● | ● | ● |

| V Type (Variable speed) | ● | ● | ● | ● | ● | ● | ● | – | – |

| P Type (Watertight) | – | – | – | ● | ● | – | ● | – | – |

Select From Maximum Air Flow

The maximum air flow for each mounting dimension is as follows.

Select Accessories

Easy Setup and Arrangement With the Accessory Set

Mounting screws, filters, and other components have been installed to finger guards to prevent fingers and foreign particles from getting inside and to the panels which provide ideal ventilating and cooling for the control cabinet.

Since this is a set, there is no need to order individual components, and you can mount it to the fan and use it immediately after arrival.

*The sets are sold separately from the fan.

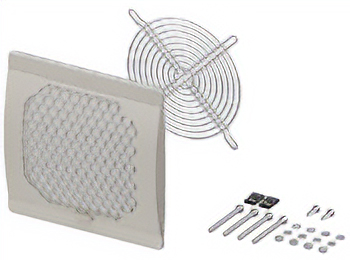

Finger Guard Set

Set Contents

Finger Guard Set (1 Guard)

- Steel Finger Guard Set

- Stainless Steel Finger Guard Set

Finger Guard Set (2 Guards)

- Steel Finger Guard Set

- Stainless Steel Finger Guard Set

Finger Guard and Filter Set (1 Each)

- Steel Finger Guard and Filter Set

Mounting Example

Finger guards are used outside the control cabinet.

- Outside → For Preventing Injury

Finger guards are used on the inside and outside of the control cabinet respectively.

- Inside → For Protection of the Workers

- Outside → For Preventing Injury

Finger guards are used on the inside of the control cabinet, and filters are used on the outside.

- Inside → For Protection of the Workers

- Outside → For Protection Against Dust

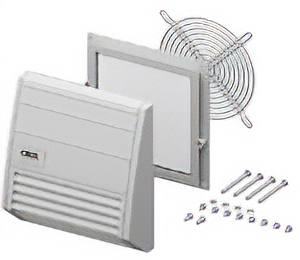

Cover Panel Set for Enclosure

Cover Panel Set Type

Cover panel set are available in varying degrees of protection. Select the right product for your needs based on the installation environment and application.

Finger Guard Cover Panel Set

IP2X Rating

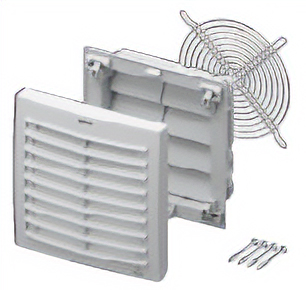

Slit Metal Cover Panel Set

IP4X Rating

Dust and Water Resistant Cover Panel Set

IP43/55 Ratings*

*The difference in ratings is due to differences in the filter product line.

IP54 Rating for Exhaust

- IP54 Rating for Suction

Assembly Figure

This is a reference diagram of the process for assembling the axial flow fan (sold separately) to the cover panel set for enclosure.

Finger Guard Cover Panel Set

IP2X rating

Slit Metal Cover Panel Set

IP4X rating

Dust and Water Resistant Cover Panel Set

IP43/55 Rating

IP54 Rating for Exhaust

IP54 rating for suction

These diagrams provide detailed information and important points such as set content, applicable products, and usage applications for each degree of protection.

Related Products

-

Obishi Keiki Seisakusho Rotary Attachment for Gear Deflection Measurement ( SHR Type )

-

UHT Corporation Timing Belt For The New GU-1 98MXL×12.7 Cylinder Polishing Unit

-

KANSAI SUS304 Double Canyoritri (Forged Product)

-

NISSAN TANAKA KT-530GX Photo Tracer Type Gas Cutting Machine

-

SAKUSAKU 4SS-20D 3.0S Carbide Square End Mill 4-Flute

-

H.H.H Tool Holder