Japan, Orientalmotor

Orientalmotor TM Series Torque Motors

Made in Japan

Manufacturer: ORIENTAL MOTOR CO., LTD.

Model: TM Series

TM Series Overview

Torque motors have a large starting torque and have a characteristic of high torque at low speed and low torque at high speed (sloping characteristics).

With this characteristic, it is usable in wide-ranging applications as a winding and tensioning motor.

Easily Adjustable Motor Torque

The TM Series can easily set and adjust the motor torque with the internal torque potentiometer of the power controller or other devices.

Recommended for Simple Winding and Tension Adjustment

Simple System Configuration

If you do not need highly accurate control using a tension controller or servo motor, you can use the TM Series to adjust tension with a simple system configuration.

Affordable Price to Start Simple Winding and Tension Adjustment

A winding and tensioning system is cheaper to configure than a tension controller or servo motor.

Power Controller Features

3 Different Torque Setting Methods to Suit Your System

Configurable torque settings include “internal torque potentiometer,” “external torque potentiometer,” and “external DC voltage.”

For external DC voltage, it can be further automated by connecting to a host PLC and controlling by DC voltage.

2-step torque setting, switching between internal and external, is also possible.

Fine Torque Adjustment Function Equipped

Relative to the set value, the actual motor output torque may vary slightly from motor to motor.

The TM Series power controllers come with a torque fine-tuning potentiometer (ADJUST function) to adjust for this variation.

When multiple motors are used, e.g. in multi-motor control, the torque difference between each motor can be easily offset.

Full Functionality

- Alarm output function to detect poor motor connection (thermal protector open detection)

- 2-step internal/external torque setting

- Instantaneous bi-directional operation by switching CW/CCW

- Sink/source logic switching for input signal

Applications

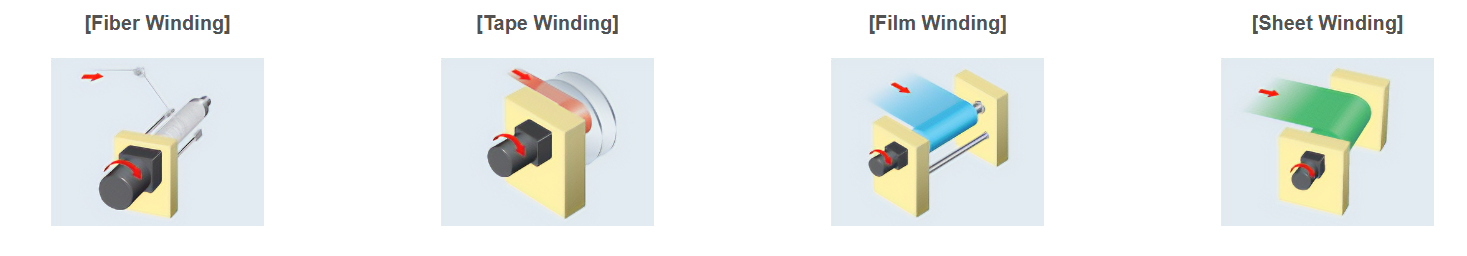

Winding

The sloping characteristics of torque motors suit applications for winding at constant speed and tension.

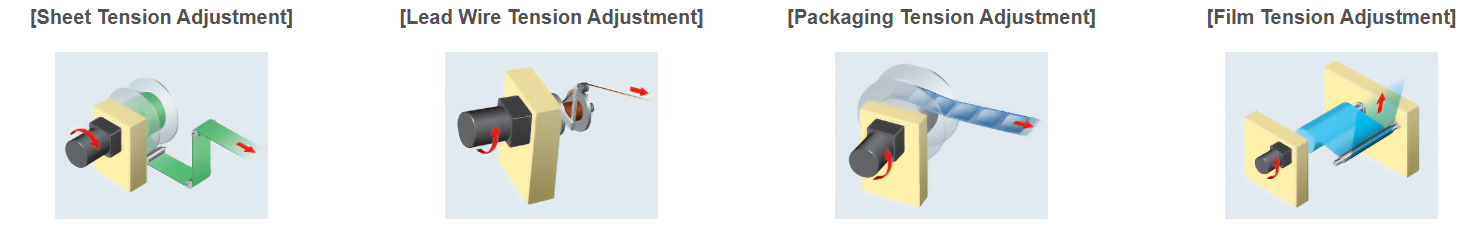

Tension Adjustment (Brake)

The brake force of the torque motor can be used for tensioning to prevent the material from sagging during winding.

Selection methods for use in winding and tension (brake) applications are described in detail in the following pages.

Pushing

Since stable torque can be obtained even under locked rotor condition or in semi-locked low speed operation, it is suitable for push-motion operation.*

Tightening

It is suitable for tightening screws, etc., since stable torque can be obtained even under locked rotor condition or in semi-locked low speed operation.*

*The output torque increases in the locked rotor condition. Never hit to stop when using a gearhead or a linear head. The gearhead or linear head may be damaged by an impact if hit to stop.

Striving for User-Friendliness

The distance between the motor and the power controller can be extended up to 20 m.

The motor and the power controller can be up to 20 meters apart.

It is usable even when the motor mounting location is far from the control cabinet.

Easy Wiring, Conforms to DIN Rail

The connection terminals of the power controller are divided into upper and lower terminals for the control and power systems, allowing for neat wiring. It can also be mounted directly on a DIN rail.

Global Voltage Support

The lineup includes products that are compatible with the power supply voltages of major countries overseas as well as Japan.

The power controller also supports a wide range of voltages, covering all major world voltages with a single unit.

Product Line

| Voltage (V) | Upper Row: Mounting Angle (mm)/Lower Row: Output Power (W) | |||

|---|---|---|---|---|

| 60 | 70 | 80 | 90 | |

| 3 | 6 | 10 | 20 | |

| Single-Phase 100 | ● | ● | ● | ● |

| Single-Phase 110/115 | ● | ● | ● | ● |

| Single-Phase 200 | ● | ● | ● | ● |

| Single-Phase 220/230 | ● | ● | ● | ● |