Osaka Manufacturing Co., Ltd.

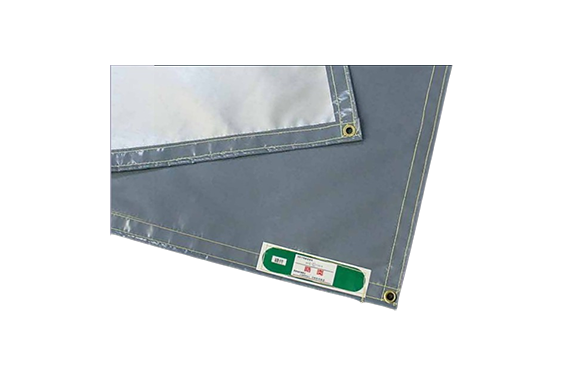

Osaka Manufacturing SG20 Protec Sheet

Manufacturer: Osaka Manufacturing Co., Ltd.Model: SG20

Product: Protec Sheet

Description

Standard Dimensions

Original size: 0.35mm (thickness) × 1,200mm (width) × 50m (length)

- 1 × 1: 1,100 × 900mm

- 1 × 2: 1,100 × 1,900mm

- 2 × 2: 2,200 × 1,900mm

- 2 × 3: 2,200 × 2,900mm

Notes:

- Made with woven P-aramid threads.

- Grid pitch approximately 500mm.

- Custom sizes are available upon request.

- P-aramid threads are resistant to long-term temperatures up to 260°C.

Material Properties

- Weight (g/m²): 476

- Tensile Strength (N/3cm): 1,961 × 1,765

- Tensile Elongation (%): 4.0 × 3.7

- Tear Strength (N): 132 × 129

- Water Resistance (1kg/3min): No leakage

Features and Safety

- Excellent heat, weather, and durability resistance.

- Outstanding dimensional stability.

- Does not emit toxic gases or produce dust.

- Suitable for various industrial applications, such as windproof curtains and partitions.

- Fireproof, heat-resistant curtains.

- Energy-saving pulp material.

- Ideal for welding spark prevention sheets.

⚠ Danger

If mishandled, this product may result in death, serious injury, or significant property damage.

- Do not perform welding, fire-handling, or related operations near flammable substances, such as oils or solvents, regardless of whether the sheet is used or not. There is a risk of fire or explosion.

⚠ Warning

If mishandled, this product may result in death, serious injury, or significant property damage.

- Always follow fire prevention regulations and proper welding procedures when performing welding.

- Avoid the following actions, as they may cause holes in the material and lead to fire or explosions:

- Exposing the material to strong acids or strong alkaline chemicals.

- Forcibly peeling off adhered “slag” (residue from welding).

- Applying a burner or flame directly to the material.

- Placing heavy objects on or dragging them across the material.

- Inspect the sheet for holes or damage before use. Do not use it if any are found.

- Do not use this material as a construction (e.g., mesh) sheet.