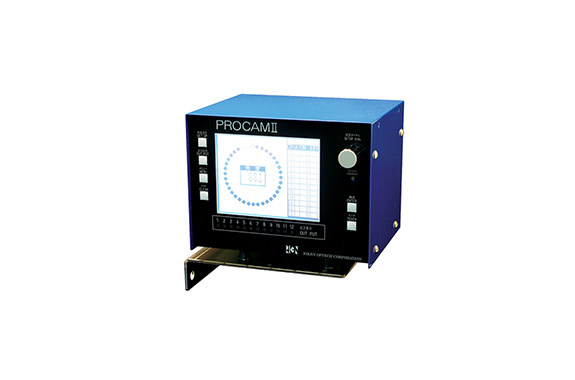

- High operability with a large and highly legible liquid crystal display.

- Teaching function allows the user to set the angle while checking operating condition.

- Memorized program Function enables to store and recall up to 41 types of angel setting.

- Adaptability to high speed operation at 1 degree in resolution up to 3000 SP.

- Stopping-time measurement function employed, that assures to help for safety press operation

Specifications

| Power Supply and Output section | Power supply | 100-240 VAC, 50/60Hz |

|---|---|---|

| Power consumption | 15W or less | |

| Output contact | Contact “B”, 1 circuit(fault output) | |

| Output contact capacity | 240 VAC or less, max.5A Cosφ=1 | |

| Cam output | NO polarity, 1 circuit(AC-SSR), common for all channels | |

| Output capacity | 240 VAC or less, max.1A Cosφ=1 | |

| Cam/transistor output | Output type : Open collector output (load:1200mA max. at less than 40VDC.) | |

| Detection section | Type | Optical rotary encoder (360PR) |

| Detection accuracy | 1 degree(max.3000spm) | |

| Display section | Display | LCD display with back light, blue mode(320 X 240 pixels) |

| Temperature compensation circuit built-in | Built-in | |

| Contrast control | External | |

| Others | Backup | Semiconductor memory, Backup time:10 years or more |

| Maximum SPM | 3000 | |

| Temperature range | Working: -10℃-50℃(non freezing) / Storage: -20℃-75℃ | |

| Humidity range | 10-85%RH (at wet bulb temperature of 29℃ or less, non condensation) |