RIKEN OPTECH CORPORATION

RIKEN OPTECH CORPORATION PMC-3 Malfunction Detector

Manufacturer: RIKEN OPTECH CORPORATION

Model: PMC-3

The standard model consolidating functions of existing detectors.

Corresponds to various applications with the condensed functions.

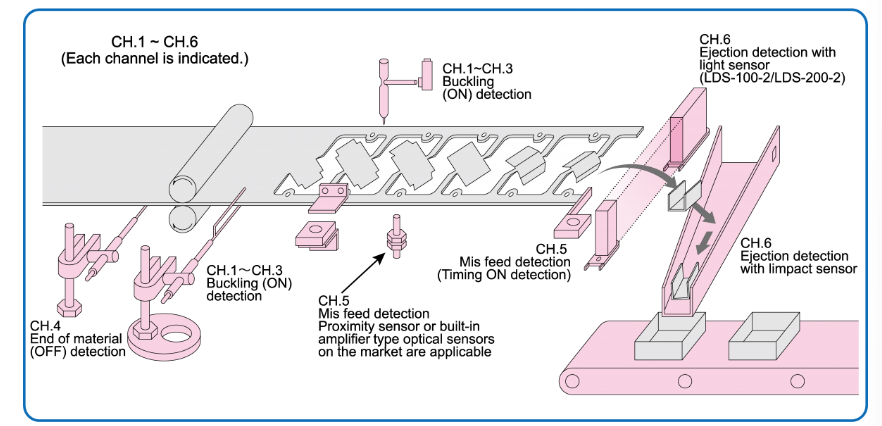

PMC3 is an indispensable multi-functional Malfunction Detector for automatic progressive press operation which

achieves high operability fully to meet diversified manufacturing process, thus promotes quality control and

improvement of productivity.

*CLT (Liquid-Crystal Display Unit) has been discontinued. We apologize for your inconvenience.

Features

- Enhance the functionality with additional units on demand.

- Counter unit is easy to see by the large-sized LED display.

- All 6 detection channels can be used with the individual timing in each.

- All 6 detection channels can be used with photoelectric sensors.

Specifications

| Power Supply and Output section | Power supply | 100-240 VAC, 50/60Hz |

|---|---|---|

| Power consumption | 10W or less | |

| Output contact | 1A, 1B (emergency stop output, auxiliary output) | |

| Output contact Capacity | 250 VAC or less, max.3A Cosφ=1 | |

| Detecting section | No.of channels | 6 channels |

| Sensor input | 6 channles | |

| Timing signal input | Independent timing signal for 6 channels and common timing signal for 1 channel (switchable from NPN to PNP and vice versa) | |

| Other Inputs | External reset, muting input and auxiliary input(switchable from NPN to PNP and vice versa) | |

| Display section | 5 X 2 two color LEDs: 6 pcs.for display of signal input, 6 pcs.for display of fault detection(stop state) and 1 pc.for display of all bypass Counter Unit: 7-segment LED | |

| Communication section (link terminal, 8P modular) | Communication standard | RS-485 |

| Communication Specifications |

| |

| Others | Response time | Max. 1 ms for each input |

| Temperature Range | Working:-10℃-50℃(non freezing) / Storage:-20℃-75℃ | |

| Humidity range | 10-85%RH (at wet bulb temperature of 29℃ or less, non condensationn) | |

| Options | Counter Unit | |

Related Products

-

RIKEN OPTECH CORPORATION 102BW Welding Glasses Fully Flexible Double Type

-

RIKEN OPTECH CORPORATION R-8 Welding Glasses Twin Lens Type

-

RIKEN OPTECH CORPORATION RLF-Ar Laser Safety Laser Safety Filter

-

RIKEN OPTECH CORPORATION RLF-SC Laser Safety Laser Safety Filter

-

RIKEN OPTECH CORPORATION RS-24UW Welding Glasses Fully Flexible Double Type

-

RIKEN OPTECH CORPORATION RLG Load Monitor