- Home

- Products

- Ross Asia 27 Series Lockout LOX Valve Safety cat. 1, PL c, pilot valve with manual lockout LOX control

Japan, Ross Asia

Ross Asia 27 Series Lockout LOX Valve Safety cat. 1, PL c, pilot valve with manual lockout LOX control

Made in Japan

Manufacturer : Ross Asia

Model : 27 Series Lockout LOX Valve

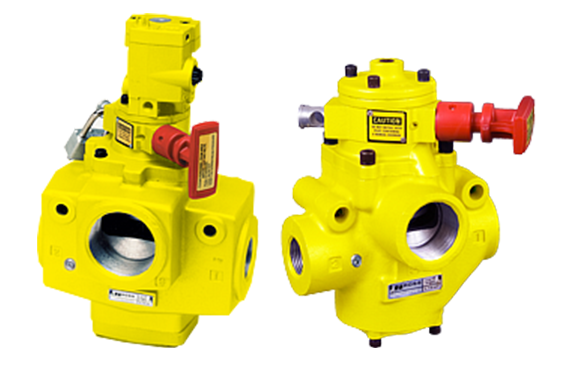

Valves with Manual Lockout L-O-X ® Control 27 Series Product Overview

Energy Isolation for Lockout/Tagout (LOTO)

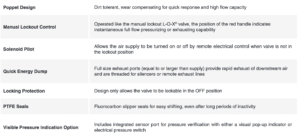

The Lockout L-O-X ® valve is used to block the supply and remove the downstream pressure from the circuit or machine and allow the employee to lockout the pneumatic energy for safe machine access. The shut-off function of the solenoid pilot controlled L-O-X ® valve is the same as that of the manual L-O-X ® valves.

The solenoid pilot and manual lockout controlled valve allows the air supply to be turned on or off by remote electrical control whenever the L-O-X ® handle is in the outward position. Air flows only if the L-O-X ® handle is outward and the solenoid pilot is energized. When the L-O-X ® handle is pushed in, air will not flow regardless of the pilot being energized or not.

Because of the poppet construction of the main valve body, air pressure provides the forces both to open the valve and to close it. These are large forces so that quick response is ensured even after the valve has been on standby for a long time.

Features

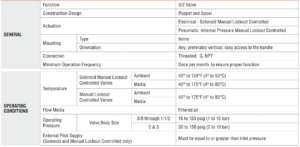

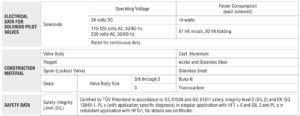

Specifications

PRODUCT CREDENTIALS

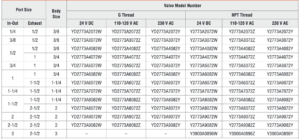

Ordering Information

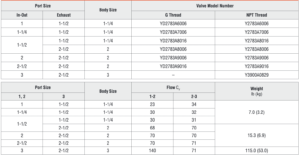

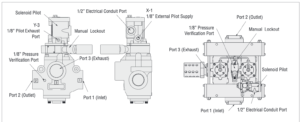

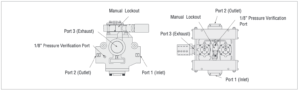

SOLENOID AND MANUAL LOCKOUT CONTROLLED VALVES(3-Way 2-Position Valves)

MANUAL LOCKOUT CONTROLLED VALVES(3-Way 2-Position Valves)

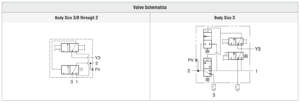

Valve Operation

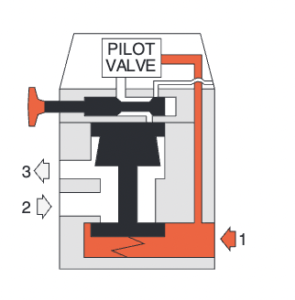

Solenoid and Manual Lockout Controlled Valves

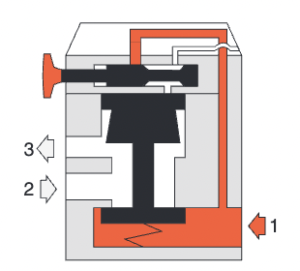

Pilot De-energized

With the solenoid pilot de-energized (regardless of the position of the L-O-X ® handle) the inlet poppet remains closed. The outlet port is connected to the exhaust port so that pressure in the downstream lines is vented to atmosphere.

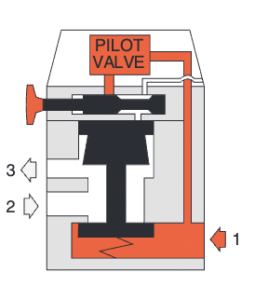

Pilot Energized

With the solenoid pilot energized and the L-O-X ® control in the open position, air can flow from inlet to outlet port. The exhaust port is closed.

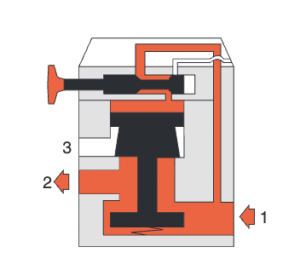

L-O-X ® Valve Closed

With the handle pushed inward, the L-O-X ® control is closed, and air to the valve piston is cut off. This allows the inlet poppet to be closed by its spring and the pressure of the inlet air. The outlet is connected to exhaust so downstream pressure is vented.

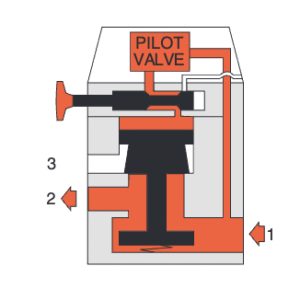

Manual Lockout Controlled Valves

Valve Closed

With a short push of the red handle inward the flow of supply air is blocked and downstream air is exhausted via the exhaust port. Air pressure on the inlet and exhaust poppets produces a large closing force. The L-O-X ® valve should be padlocked in this position to prevent the handle from being pulled outward inadvertently when potential for human injury exists or servicing machinery.

Valve Open

With the red handle pulled out, pilot air flows to the top of the actuating piston, causing it to open the inlet poppet. Supply air then flows freely from inlet to outlet, and the exhaust port is blocked. A detent keeps the L-O-X ® handle in the open position. The handle is designed not to be locked in the open position, thereby allowing for quick shut off when necessary.

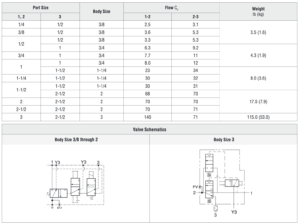

Valve Technical Data

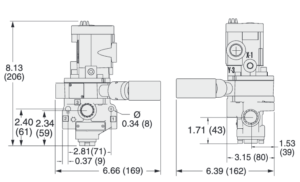

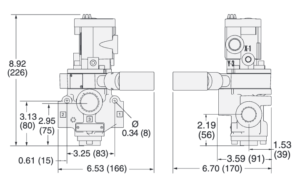

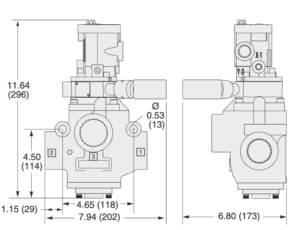

Solenoid and Manual Lockout Controlled Valves

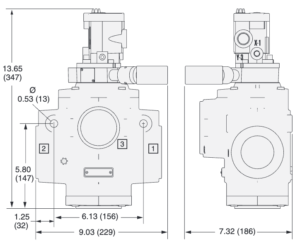

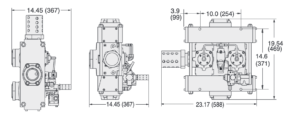

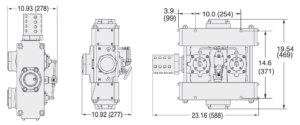

| Dimensions-Inches(mm) | |

| Body Size 3/8 |  |

| Body Size 3/4 |  |

| Body Size 1-1/4 |  |

| Body Size 2 |  |

| Body Size 3 |  |

Manual Lockout Controlled Valves

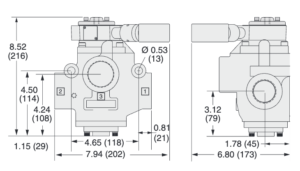

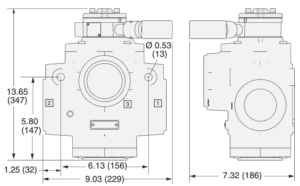

| Dimensions-Inches(mm) | |

| Body Size 1-1/4 |  |

| Body Size 2 |  |

| Body Size 3 |  |

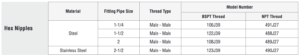

Accessories

ENERGY RELEASE VERIFICATION

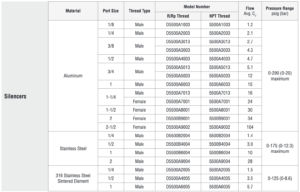

EXHAUST SILENCERS

FEMALE SILENCER CONNECTORS

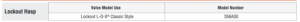

LOCKOUT DEVICE

SOLENOID PILOT OPTIONS