Japan, Ross Asia

Ross Asia 27 Series Soft Start-EEZ-On Valve Safety cat. 1, PLc

Made in Japan

Manufacturer : Ross Asis

Model : 27 Series Soft Start-EEZ-On Valve

Soft-Start EEZ-ON ® Valves 27 Series Product Overview

Soft-Start

The EEZ-ON ® valve is designed to allow a gradual buildup of downstream air pressure before opening to full air flow.

This gradual pressure buildup allows cylinders and other work elements to move slowly and more safely into their normal working positions before full line pressure is applied.

The 3/2 valves have an exhaust port so that downstream air is exhausted when the valve is de-energized. At the same time, supply air is positively shut off so that a separate shut-off valve is not required.

VALVE FEATURES

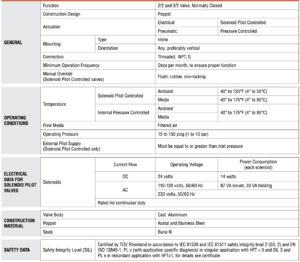

Specification

PRODUCT CREDENTIALS

PRODUCT CREDENTIALS

Ordering Information

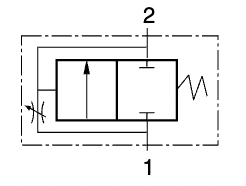

INTERNAL PRESSURE CONTROLLED(2-Way 2-Position Valves)

| Valve Schematic | |

|

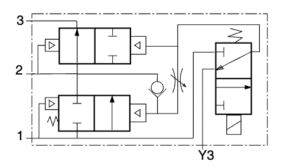

SOLENOID PILOT CONTROLLED(3-Way 2-Position Valves)

| Valve Schematic | |

|

INTERNAL PRESSURE CONTROLLED(3-Way 2-Position Valves)

| Valve Schematic | |

|

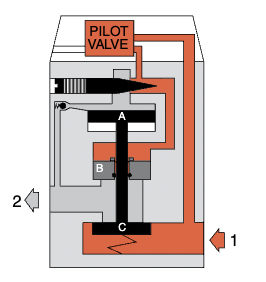

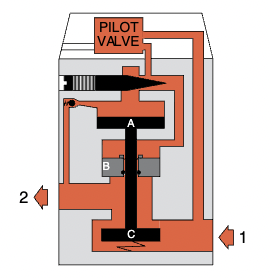

Valve Operation

| Solenoid Pilot Controlled Valves | |

| Pilot Not Energized | Pilot air is blocked by the pilot. Any downstream pressure forces piston B (which slides on the valve stem) upward. This opens the exhaust port and vents the downstream line |

| |

| Pilot Energized | Pilot air forces piston B downward to close the exhaust port. Pilot air also flows past the adjusting needle, opens the ball check and begins slowly to pressurize the outlet line. At the same time, pressure is building up on piston A |

| |

| Full Pressure | When the pressure on piston A reaches approximately 50 percent of inlet pressure, it is forced downward and opens inlet poppet C. Full inlet pressure now flows freely to the outlet port |

| |

| Pilot De-energized | Air above pistons A and B is exhausted through the exhaust port of the pilot valve. Air above poppet C forces sliding piston B upward so that the main exhaust port is opened and the pressurized air is exhausted |

| |

| Internal Pressure Controlled Valves | |

| Air Pressure to Inlet | When air pressure is first applied to the inlet, air flow to the piston is restricted by the adjustable needle in the delay orifice. Downstream air pressure gradually builds up at a rate determined by the setting of the adjustable needle |

| |

| Inlet Pressure Removed | When inlet pressure is removed, the exhausting downstream air pressure keeps the inlet poppet open until the downstream pressure drops by approximately 90 percent. The remaining pressure is exhausted via the delay orifice. |

| |

| Valve Opens to Full Flow | When downstream air pressure reaches approximately 40 to 60 percent of inlet pressure, the valve element shifts to the full open position and there is full air flow to the downstream components. This condition continues as long as inlet air pressure is present. |

| |

Valve Technical Data

2/2 Pressure Controlled Valves

| Dimensions-Inches(mm) | |

| Body Size 3/8 |  |

| Body Size 3/4 |  |

| Body Size 1-1/4 |  |

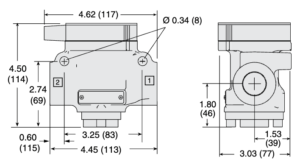

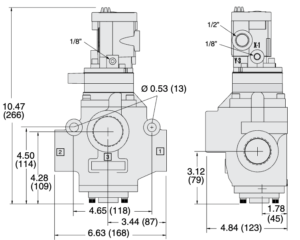

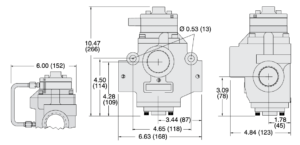

3/2 Solenoid Pilot Controlled Valves

| Dimensions-Inches(mm) | |

| Body Size 3/8 |  |

| Body Size 3/4 |  |

| Body Size 1-1/4 |  |

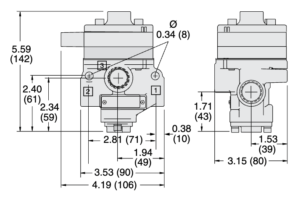

3/2 Pressure Controlled Valves

| Dimensions-Inches(mm) | |

| Body Size 3/8 |  |

| Body Size 3/4 |  |

| Body Size 1-1/4 |  |

Accessories

Accessories

ENERGY RELEASE VERIFICATION

EXHAUST SILENCERS

FEMALE SILENCER CONNECTORS

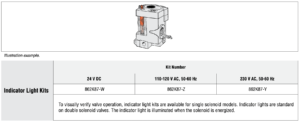

SOLENOID PILOT INDICATOR LIGHT KITS

SOLENOID PILOT MANUAL OVERRIDE KITS