Japan, Ross Asia

Ross Asia Double valve for clutch/brake control DM2® Series D, Self-Monitoring

Made in Japan

Manufacturer : Ross Asia

Model : Double valve for clutch

DM 2® Series D Clutch/Brake Control Double Valves Product Overview

Clutch/Brake Control Function

The DM 2® Series D double valve is designed to provide SAFETY for the operators and maintenance personnel working on presses.

The DM2®Series D double valve is a patented 3/2 normally closed valve (with an intermediate, lockout position) distinguished by SERPAR ® Crossflow passages with poppet and spool valving on the main valve stems. This arrangement provides the valve’s outstanding flow characteristics and an integrated monitoring capability with total memory. The valve provides dynamic monitoring and dynamic memory.

Dynamic Monitoring means that all monitoring components change state on every valve cycle. Should the valve elements cycle asynchronously, the valve will exhaust downstream air and lock-out, prohibiting further operation.

Dynamic Memory within a monitoring system indicates that when a valve lock-out occurs, the valve will retain the fault information regardless of air or electrical changes. The DM2® system can only be reset by a defined operation/procedure, and will not self-reset (turning the valve off and on) or reset when inlet air supply is removed and re-applied. Such automatic resetting would conceal potential hazards from the operator.

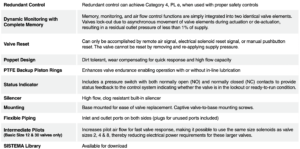

VALVE FEATURES

PRODUCT CREDENTIALS

Specification

Ordering Information

MODEL NUMBER CONFIGURATOR(3-Way 2-Position Valves)

Valve Operation

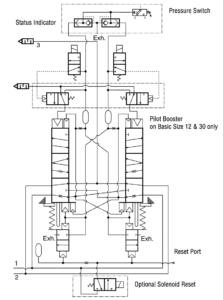

| Valve De-actuated (ready-to-run) | The flow of inlet air pressure into the crossover passages is restricted by the size of the passage between the stem and the valve body opening. Flow is sufficient to quickly pressurize pilot supply/timing chambers A and B. The inlet poppets prevent air flow from crossover passages into the outlet chamber. Air pressure acting on the inlet poppets and return pistons securely hold the valve elements in the closed position. (Air passages shown out of position and reset adapter omitted for clarity. |

| |

| Valve Actuated | Energizing the pilot valves simultaneously applies pressure to both pistons, forcing the internal parts to move to their actuated (open) position, where inlet air flow to crossover passages is fully open, inlet poppets are fully open and exhaust poppets are fully closed. The outlet is then quickly pressurized, and pressure in the inlet, crossovers, outlet, and timing chambers are quickly equalized. De-energizing the pilots quickly causes the valve elements to return to the ready-to-run position. |

| |

| Resetting the Valve | The valve will remain in the locked-out position, even if the inlet air supply is removed and re-applied. A remote reset signal (air or electric), or a manual push button actuation must be applied to reset the valve. Reset is accomplished by momentarily pressurizing the reset port. Actuation of the reset piston physically pushes the main valve elements to their closed position. Inlet air fully pressurizes the crossovers and holds the inlet poppets on seat. Actuation of the reset piston opens the reset poppet, thereby, immediately exhausting pilot supply air, thus, preventing valve operation during reset. (Reset adapter added to illustration.) De-actuation of reset pistons causes the reset poppets to close and pilot supply to fully pressurize. Reset air pressure can be applied by a remote 3/2 normally closed valve, or from an optional 3/2 normally closed solenoid, or a manual push button mounted on the reset adapter. |

| |

| Valve Locked-out | Whenever the valve elements operate in a sufficiently asynchronous manner, either on actuation or de-actuation, the valve will move to a locked-out position. In the locked-out position, one crossover and its related timing chamber will be exhausted, and the other crossover and its related timing chamber will be fully pressurized. The valve element (side B) that is partially actuated has pilot air available to fully actuate it, but no air pressure on the return piston to fully de-actuate the valve element. Air pressure in the crossover acts on the differential of side B stem diameters creating a latching force. Side A is in a fully closed position, and has no pilot air available to actuate, but has full pressure on the inlet poppet and return piston to hold the element in the fully closed position. Inlet air flow on side A into its crossover is restricted, and flows through the open inlet poppet on side B, through the outlet into the exhaust port, and from the exhaust port to atmosphere. Residual pressure in the outlet is less than 1% of inlet pressure. The return springs are limited in travel, and can only return the valve elements to the intermediate (locked-out) position. Sufficient air pressure acting on the return pistons is needed to return the valve elements to a fully closed position. |

| |

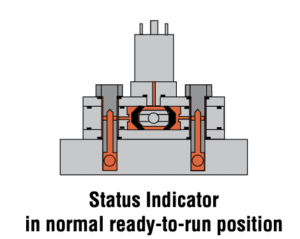

| Status Indicator | The status indicator pressure switch will actuate when the main valve is operating normally, and will de-actuate when the main valve is in the locked-out position or inlet pressure is removed. This device is not part of the valve lockout function, but, rather, only reports the status of the main valve. |

| |

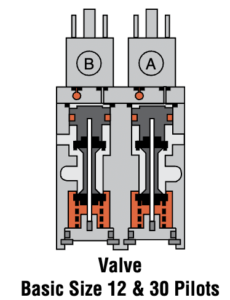

| Basic Size 12 and 30 valves require relatively large pilots to actuate and de-actuate the main valve elements. In order to achieve extremely quick valve response for such large pilots, a 2-stage solenoid pilot system is incorporated into the design. This keeps the required electrical current to operate the pilots to a minimum. |

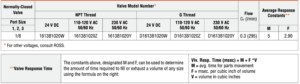

Valve Technical Data

| Valve Schematic | |

|

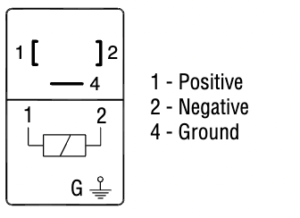

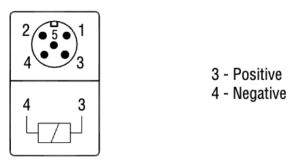

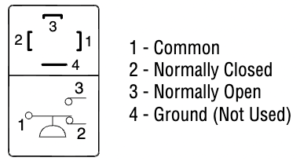

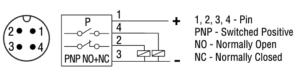

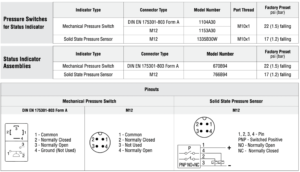

| Solenoid & Pressure Switch Pinouts | ||

| Solenoid | DIN EN 175301-803 Form A | M12 |

|  | |

| Pressure Switch |  |  |

VALVE RESPONSE CHARTS

The charts below represent the fill and exhaust times for each of the various sizes of DM 2® Series D double valves. The “fill” times were measured while raising (filling) the pressure in a volume from 0 to 30, 60, & 80 psi (0 to 2.1, 4.1, & 5.5 bar) with a 90 psi (6.2 bar) inlet pressure. Conversely, the “exhaust” times were measured while lowering the pressure (exhausting) in a volume from 90 psi (6.2 bar) down to 90 to 60, 30, & 9 psi (4.1, 2.1, & 0.6 bar). Exhausting tests performed with silencer installed.

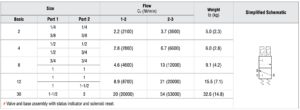

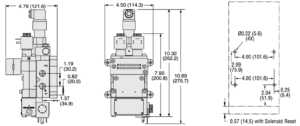

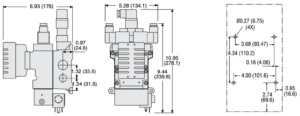

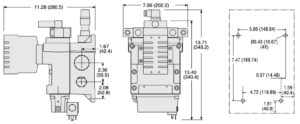

| Dimensions-Inches(mm) | ||

| Basic Size | Port Size | View X (base mounting hole pattern) |

| 2 | 1/4 3/8 |  |

| 4 | 1/2 |  |

| 8 | 3/4 1 |  |

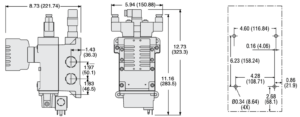

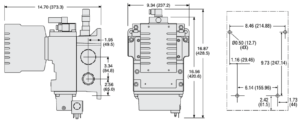

| Dimensions-Inches(mm) | ||

| Basic Size | Port Size | View X (base mounting hole pattern) |

| 12 | 1 |  |

| 30 | 2 |  |

Accessories

ELECTRICAL STATUS INDICATION

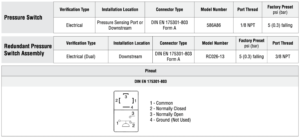

ENERGY RELEASE VERIFICATION

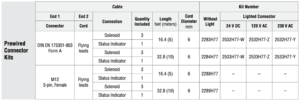

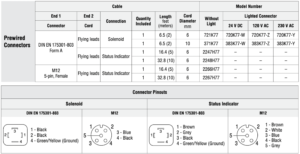

PREWIRED ELECTRICAL CONNECTORS

ELECTRICAL CONNECTORS

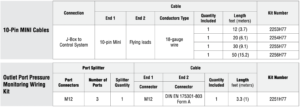

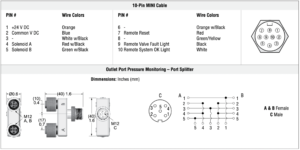

JUNCTION BOX OPTIONS

JUNCTION BOX OPTIONS

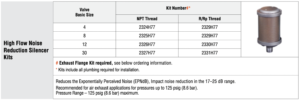

EXHAUST SILENCERS

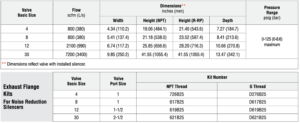

RESET VALVES FOR DOUBLE VALVES WITH REMOTE RESET

Valves with the remote reset option require a small 3/2 reset valve and the installation of a 1/8 inch air line from the reset valve to the reset port of the double valve. ROSS offers 3/2 normally closed valves with either manual or electric control that are suitable for this purpose.

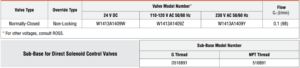

Direct Solenoid Pilot Control – Compact Valves for Line Mounting

Direct Solenoid Pilot Control – Miniature Valve for Base Mounting

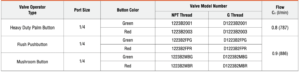

Manual Palm Button Valves

Related Products

-

Super Tool KPH27/32/36 Offset Wrench For Shear Bolt Use (With Corn Shaped Spear, 70° Type)

-

LOBTEX WP-D (G・R・B・Y・V・S)Anguirus, Water Pump Pliers (with screwdriver) Skeleton

-

KONAN CP611AR Pneumatic Cylinder Rod-out stroke Adjustable Type

-

Organo Olpersion E200 Slime Control Agent For RO Membrane

-

Precision Oven

-

Kakuta No.HV250 Hold Down Clamp