Japan, Ross Asia

Ross Asia Serial bus Uses ROSS & Turck modular I/0

Made in Japan

Manufacturer :Ross Asia

Model : Serial bus

ROSS Serial Bus System with TURCK Modular I/O – KEY FEATURES

- A complete Centralized Serial Bus communication offering for ISO valves W65 and W66 Series.

- I/O system based on the TURCK Modular Industrial I/0 System BL 67.

- Communication module supports up to 32 station modules each supporting up to 8 I/O modules.

- Input modules accept signals from sensors, photo eyes, limits and other field input devices.

- Output modules provide signals to remote solenoid valves and other field output devices.

- UL, C-UL, and CE certified.

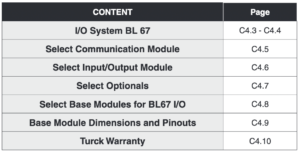

Modular Industrial I/O System BL 67

TURCK Serial Bus System

The BL67 Solution

BL67 combines all the flexibility of an in-the-cabinet PLC I/O system with modularity, ruggedness and connectorization.

BL67 complements the AIM™, BL20 and piconet ® product families to meet the needs of unique applications, such as small machine or conveyor systems requiring IP 67 protection.

The BL67 Concept

The BL67 modular concept is a very flexible approach to connectorized I/O. The gateway, base and electronic modules provide many benefits to the user.

- The gateway provides communication between the fieldbus and I/O modules; modules are not dependent on the fieldbus protocol.

- DIN-rail or frame mountable base modules are available with eurofast ® (M12), minifast ® (7/8-16UN), M23 and picofast ® (M8) connectors.

- Electronic modules are hot swappable•

- Power distribution module (24 volts DC) supplies the connected I/O signals

BL67’s openness, flexibility, connectorization, compact housing and ruggedness provide a viable alternative to in-the cabinet I/O.

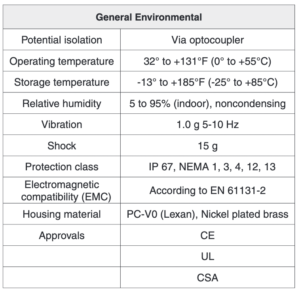

Environmental Conditions

Intended Application Environments

- BL67 does not need an enclosure

- Mount directly on machine or conveyor

- Rugged design provides protection against dirt, dust and liquids

Not intended for These Environments

- Continuous submersion

- 100 percent humidity

- High pressure washdown

Note: For higher levels of protection consider fully potted AIM stations

Maximum Size of a BL67 Station

BL67 stations consist of a gateway and a maximum of 32 modules (equivalent to 1 m station length). Some high-tech and analog I/O modules may consume or produce large amounts of data, and therefore may limit the number of modules that may be used per system. It is highly recommended that the I/O assistant software is used when planning and commissioning BL67 systems. This program allows you to build the BL67 node on your computer and verify that all restrictions with regard to power and size are met. The free I/O assistant software is available for download from www.turck.com.

Addressing

As a node on a network, BL67 stations are addressed dependent on the network system being used. Each network gateway has a set of rotary switches used to set the address for the node. DeviceNet™ and CANopen gateways may be addressed between 0 and 63 via two switches (one for the 10’s digit and one for the 1’s digit). For example, to set the address to 37 you would set the 10’s switch to 3 and the 1’s switch to 7. The third switch on the gateway may be used to set the communication rate of the network interface. PROFIBUS ® -DP gateways may be set from 1 to 125 by using three switches (one for the 100’s, one for the 10’s and one for the 1’s).

Ethernet gateways allow different addressing schemes depending on the Ethernet addressing method being used in the overall system.

Dynamic addressing schemes include BootP and DHCP, while hard-coding a static address is also allowed. TURCK Serial Bus System Modular Industrial I/O System BL 67.

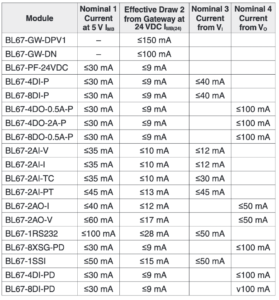

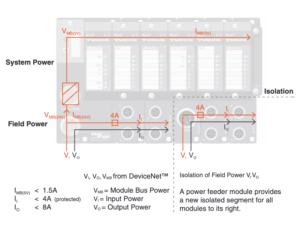

BL67 Power Distribution

Power Overview

The power supply for a BL67 station is fed via the power connector on the PROFIBUS ® gateway or directly from the network on the DeviceNet™ gateway. Power feeder modules can be added to the system at any point to provide a fresh isolated supply of power to all I/O connected to its right.

Internal Power Consumption via Module Bus

The amount of BL67 modules that may be supplied via the internal module bus depends on the respective nominal current IMB of the individual modules on the module bus. The sum of the nominal current inputs of the connected BL67 module must not exceed 1.5 A. If the I/O assistant software is used, an error message is generated automatically via the <Station – Verify> as soon as the system supply via the module bus is no longer sufficiently guaranteed.

To calculate current draw on DeviceNet: Add IMB(24) for all modules. Then add VI and VO for electronic modules to the left of the first power feed module. Next, add the current draw of the I/O devices.

To calculate current draw on PROFIBUS gateway power connector for VI: Add IMB for all modules. Then add VI current for all modules to the left of the first power feed module. Next, add the current draw of the input devices.

For VO, add the VO current for all modules to the left of the first power feed module. Next, add the current draw of the output devices.

VMB = Module bus power

VI = Input power

VO = Output power

IMB = Module bus current

IMB(24) = Effective current draw from gateway at 24 volts DC supply.

Applying Power to BL67

PROFIBUS ®, Ethernet and CANopen System

DeviceNet TM System

Electrical:

- Operating Current: <600 mA from V MB

- Input Supply Current: <4 A (from V I )

- Output Supply Current: <8 A (from V O )

- Backplane Current: <1.5 A (from V MB)

Mechanical:

- Operating Temperature: -12 to +55°C (-13 to +131°F)

- Protection: IP 67

- Vibration: 5 g @ 10-500 Hz

Material:

- Housing: PC-V0 (Lexan)

Diagnostics (Logical)

- Diagnostic information available through the DeviceNet I/O map

Diagnostics (Physical)

- LEDs to indicate status of DeviceNet and Module Bus communication

Programmability

- PG in model number designates a programmable gateway

- Progammable according to IEC 61131.3 using CodeSy (includes ladder logic)

- Use CodeSys to create logic programs to control local I/O

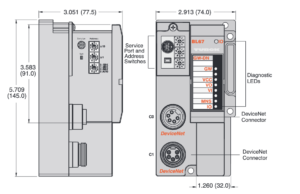

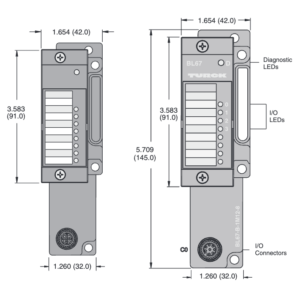

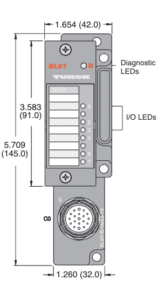

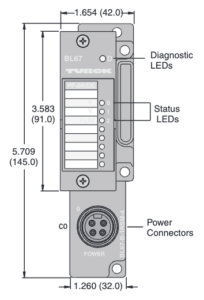

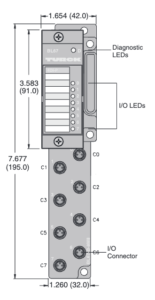

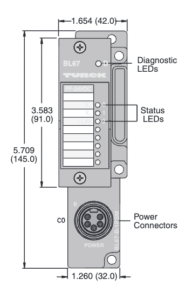

Dimensions – inches (mm)

Step 2

Select Input/Output Module

Power Distribution

Inputs: V1

Outputs: V0

Logic: VMB

Mechanical:

Operating Temperature: +32 to +131°F (0 to +55°C)

Protection: NEMA 1,3,4,12,13 / IEC IP 67

Vibration: 5 g @ 10 – 500 Hz

Material:

Connectors: Nickel-plated brass

Housing PC-VO (Lexan)

Diagnostics (Logical)

Diagnostic information available through the fieldbus gateway

Diagnostics (Physical)

LEDs to indicate status of DeviceNet and Module Bus communication

LEDs for each I/O point to indicate on/off status

Step 3

Select Optionals

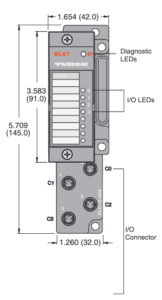

Select Optional CANopen Interface / Serial Communication Modules

Power Distribution

Inputs: V1

Outputs: V0

Logic: V MB

Mechanical:

Operating Temperature: +32 to +131°F (0 to +55°C)

Protection: NEMA 1,3,4,12,13 / IEC IP 67

Vibration: 5 g @ 10 – 500 Hz

Material:

- Connectors: Nickel-plated brass

- Housing: PC-VO (Lexan)

Diagnostics (Logical)

- Diagnostic information available through the fieldbus gateway

Diagnostics (Physical):

- LED to indicate module bus communication status as well as I/O diagnostics

- LEDs for each I/O point to indicate on/off status

Functional Description

- Connect up to 8 CANopen slaves to this module

- Map the slaves into any available fieldbus

Select Optional CANopen Interface / Serial Communication Modules

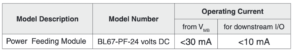

Electrical:

Operating CurrentInputs: V1

Outputs: V0

Logic: VMB

Power Distribution:

Accepts 24 volts DC supply to provide V1 and V0 for downstream modules

Material:

Connectors: Nickel-plated brass

Housing PC-VO (Lexan)

Diagnostics (Logical)

Diagnostic information available through the fieldbus gateway

Diagnostics (Physical)

LEDs to indicate status of DeviceNet and Module Bus communication

LEDs for each I/O point to indicate on/off status

Step 6

Select Base Modules for BL67 I/O

Labels for labeling electronic modules

BL67-Label/DIN-A4-50-PCS

Programming Cable –

For connecting the BL20/BL67 system to

the I/O Assistant software

XN-PS2-CABLE

DIN A4 sheet size

DIN A4 sheet sizeBase Module Dimensions and Pinouts

| Dimensions – inches (mm) | |||

| eurofast® | picofast® | M23 | minifast |

|

|

|

|

|

|

|

|