Sakai

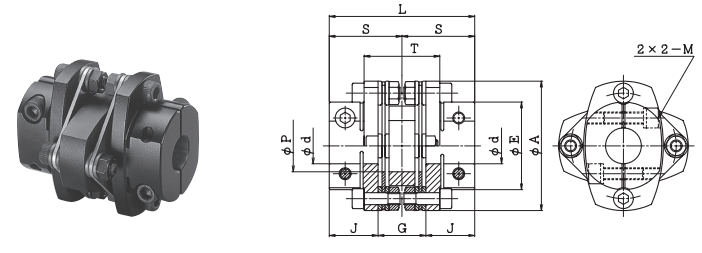

Sakai LCD-B Series Precision Spring Coupling

Manufacturer: Sakai Manufacturing Co., Ltd.

Model: LCD-B Series

Features

- Streamlined body results in low inertia specifications.

- Unique laminated leaf spring with excellent precision and rigidity used as flexure material. Bolting two sets of laminated leaf springs to the hub creates a non-backlash structure and high flexibility, achieving high precision and high torque rotation transmission.

- Two sets of laminated leaf springs sandwiched between spacers absorb eccentricity, angular misalignment, and axial displacement. A precision shaft coupling combines high versatility, high flexibility, easy centering, and high precision rotation transmission.

Specifications

(Dimensions: mm)

| Model number | d | A | E | P | L | S | T | J | G | M |

|---|---|---|---|---|---|---|---|---|---|---|

| LCD-45B | 8~16 | 45 | 31 | 18 | 52 | 26 | 28 | 17 | 18 | M4 |

| LCD-55B | 10~19 | 55 | 38 | 21 | 60 | 30 | 32 | 20 | 20 | M5 |

| LCD-65B | 12~ 25 | 65 | 44 | 26 | 73 | 36.5 | 38 | 24.5 | 24 | M6/M5 |

| LCD-80B | 12~35 | 80 | 57 | 36 | 83 | 41.5 | 39 | 29 | 25 | M8/M6 |

| LCD-90B | 17~35 | 90 | 63 | 37 | 96 | 48 | 54 | 31 | 34 | M8 |

| LCD-100B | 20~40 | 100 | 70 | 41 | 109 | 54.5 | 57 | 36 | 37 | M10/M8 |

| LCD-125B | 32~42 | 125 | 88 | 51 | 130 | 65 | 71 | 42.5 | 45 | M12 |

| LCD-155B | 45~60 | 155 | 112 | 61 | 154 | 77 | 84 | 50 | 54 | M14 |

| Model number | Allowable torque N・m | Allowable eccentricity mm | Allowable deviation angle ° | Allowable axial displacement mm | Maximum rotation speed min-1 | Torsional stiffness | Axial spring constant N/mm | Moment of inertia kg・m2 | Mass kg | |

|---|---|---|---|---|---|---|---|---|---|---|

| Overall N・m/rad | Leaf spring only N・m/rad | |||||||||

| LCD-45B | 12 | 0.23 | 1 | ±0.65 | 10,000 | 0.74×104 | 1.25×104 | 29 | 0.51×10-4 | 0.24 |

| LCD-55B | 25 | 0.27 | 1 | ±0.79 | 10,000 | 1.47×104 | 2.50×104 | 29 | 1.36×10-4 | 0.43 |

| LCD-65B | 40 | 0.32 | 1 | ±0.93 | 10,000 | 2.94×104 | 1.30×105 | 62 | 3.20×10-4 | 0.7 |

| LCD-80B | 80 | 0.33 | 1 | ±1.15 | 10,000 | 5.88×104 | 1.02×105 | 37 | 7.79×10-4 | 1.11 |

| LCD-90B | 180 | 0.45 | 1 | ±1.27 | 10,000 | 8.82×104 | 1.95×105 | 45 | 1.56×10-3 | 1.76 |

| LCD-100B | 250 | 0.47 | 1 | ±1.43 | 10,000 | 1.18×105 | 3.30×105 | 53 | 2.65×10-3 | 2.46 |

| LCD-125B | 400 | 0.58 | 1 | ±1.79 | 10,000 | 2.06×105 | 6.50×105 | 42 | 8.28×10-3 | 5.12 |

| LCD-155B | 800 | 0.7 | 1 | ±2.25 | 10,000 | 3.23×105 | 1.15×105 | 29 | 2.39×10-2 | 9.28 |

Standard Shaft Hole Diameter: d

(Unit: mm)

| Model number | d | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 8 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | |

| LCD-45B | ● | ● | ● | ● | ● | ● | ● | ● | – | – | – | – | – | – | – | – | – | – | – | – | – | – |

| LCD-55B | – | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | 🟤 | – | 🟤 | – | – | – | – | – | – | – | – |

| LCD-65B | – | – | – | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | – | – | – | – | – | – | – |

| LCD-80B | – | – | – | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | – | – | – |

| LCD-90B | – | – | – | – | – | – | – | – | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | – | – | – |

| LCD-100B | – | – | – | – | – | – | – | – | – | – | – | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | – |

| LCD-125B | – | – | – | – | – | – | – | – | – | – | – | – | – | – | 🟤 | 🟤 | 🟤 | ● | ● | ● | ● | ● |

| Model number | d | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 60 | |

| LCD-155B | 🟤 | 🟤 | 🟤 | 🟤 | ● | ● | ● | ● | ● |

- The moment of inertia and mass are calculated, the shaft hole diameter is at its maximum.

- Be sure to insert the mounting shaft up to the J dimension.

- The recommended shaft tolerance is h6. (Shaft diameter 35mm, tolerances of 0 to +0.010 are supported.)

- The allowable axial displacement represents the case the deviation angle is zero.

- The maximum rotation speed does not take dynamic balance into consideration.

- The 🟤 mark indicates a non-standard hole diameter (delivery confirmation hole diameter).