Sakai

Sakai UCN-T7 Series Precision Compensation Coupling

Manufacturer: Sakai Manufacturing Co., Ltd.

Model: UCN-T7 Series

Feature

- By using a taper clamp specification, shaft tightening can be achieved with a small tightening torque

Performance

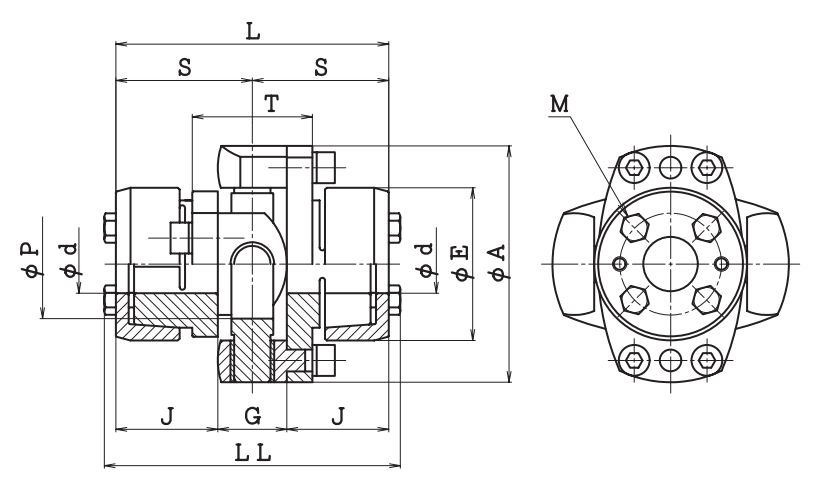

(Dimensions: mm)

| Model | Allowable Torque (N·m) | Maximum Torque (N·m) | Allowable Thrust Load (N) | Allowable Eccentricity (mm) | Allowable Angular Misalignment (°) | Max Rotational Speed (min⁻¹) | Torsional Stiffness (N·m/rad) | Moment of Inertia (kg·m²) | Mass (kg) |

|---|---|---|---|---|---|---|---|---|---|

| UCN-65T7 | 40 | 80 | 1450 | 0.2 | 1 | 6000 | 1.08×10⁵ | 3.15×10⁻⁴ | 0.76 |

| UCN-80T7 | 80 | 160 | 2350 | 0.2 | 1 | 6000 | 2.37×10⁵ | 8.20×10⁻⁴ | 1.16 |

| UCN-100T7 | 160 | 320 | 3750 | 0.2 | 1 | 6000 | 4.66×10⁵ | 2.52×10⁻³ | 2.32 |

| UCN-125T7 | 320 | 640 | 6000 | 0.2 | 1 | 6000 | 8.80×10⁵ | 7.09×10⁻³ | 4.38 |

| UCN-155T7 | 640 | 1280 | 9750 | 0.2 | 1 | 6000 | 1.66×10⁶ | 1.93×10^-2 | 7.51 |

| Model | d | A | E | P | L | LL | S | T | J | G | M |

|---|---|---|---|---|---|---|---|---|---|---|---|

| UCN-65T7 | 14~20 | 65 | 47 | 30 | 75 | 81 | 37.5 | 33 | 28 | 19 | M4 |

| UCN-80T7 | 16~35 | 80 | 60 | 39 | 88 | 95 | 44 | 36 | 33 | 22 | M4/M5 |

| UCN-100T7 | 22~40 | 100 | 74 | 45 | 102 | 109 | 51 | 48 | 37 | 28 | M5 |

| UCN-125T7 | 32~42 | 125 | 86 | 61 | 122 | 129 | 61 | 61 | 43.5 | 35 | M5 |

| UCN-155T7 | 45~60 | 155 | 108 | 76 | 143 | 151 | 71.5 | 71 | 51 | 41 | M6 |

Standard Shaft Hole Diameter: d

Model | d | |||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 14 | 15 | 16 | 17 | 18 | 19 | 20 | 22 | 24 | 25 | 28 | 30 | 32 | 35 | 38 | 40 | 42 | 45 | 48 | 50 | 55 | 60 | |

| UCN-65T7 | ● | ● | ● | ● | ● | ● | ● | |||||||||||||||

| UCN-80T7 | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ● | ||||||||||

| UCN-100T7 | ● | ● | ● | ● | ● | ● | ● | ● | ● | |||||||||||||

| UCN-125T7 | ● | ● | ● | ● | ● | |||||||||||||||||

| UCN-155T7 | ● | ● | ● | ● | ● | |||||||||||||||||

- Confirm delivery time for UCN-125T7 and UCN-155T7, which are standard products.

- Indicate permissible torque at 1500 min⁻¹ rotational speed.

- Transmit maximum torque momentarily startup and braking.

- Represent permissible thrust load as the static permissible load with zero load torque.

- Apply torsional rigidity value to the metal part only.

- Represent moment of inertia and mass as maximum values at the largest outer diameter.

- Insert the key securely using the recommended method.

- Use recommended tolerance H6. (Accommodate h9 tolerance for a 35 mm shaft diameter.)

- Use at an offset or angle greater than the permissible value if conditions allow. Contact us for more information.