Sanshin

Sanshin Econoselfy® On-site regenerative ion exchange equipment

Manufacturer: Sanshin Manufacturing Co., Ltd

Model: cylinder

This is a cylinder-type ion exchange device that uses an on-site regeneration system to easily recycle washing wastewater. By using this device, you can obtain stable, high-purity water, reduce the amount of water used in your factory, and reduce the amount of wastewater.

Features

- Various combinations are possible depending on the usage situation.

The optimal combination and capacity of ion exchange resin can be selected depending on the type of recycled raw water and the required amount. - The installation area is small, so it can be easily installed even in tight spaces.Compared

to our previous products, the installation area is reduced by 30% and the operating weight is reduced by 20%, making it lightweight.Water recycling can be started with simple on-site wiring and piping work. - Easy-to-use regeneration device.

Simple valve operation is all that is required, and no hose switching is required during regeneration. We also have a lineup of fully automatic regeneration devices with automatic valve switching operation.

Standard specification regeneration unit

| Model | W1XC-2PH/W1XC-3PH | W1XC-2PA/W1XC-3PA |

|---|---|---|

| Playback method | Manual regeneration | Automatic regeneration |

| Simultaneous playback | 2 tower type/3 tower type | 2 tower type/3 tower type |

| Water connection diameter | 15A | 15A |

| Drainage connection diameter | 20A | 20A |

| Power capacity (50/60Hz) | AC200V 0.5kw | AC200V 0.6kw |

| External dimensions: 2-tower type [width x depth x height] | 890×900×1,640mm | 890×1,120×1,815mm |

| External dimensions: 3-tower type [width x depth x height] | 940×900×1,900mm | 940×1,120×2,000mm |

*Standard accessories: Conductivity meter, water tank, operation panel, hose for connecting to ion exchange tower

Standard specification water flow unit

| Model | W1P-2013LR/W1P-3013LR | W1P-2025LR/W1P-3025LR | W1P-205LR/W1P-305LR |

|---|---|---|---|

| Number of ion exchange towers | 2 tower type/3 tower type | 2 tower type/3 tower type | 2 tower type/3 tower type |

| Resin volume (L tower) | 12.5 | twenty five | 50 |

| Maximum flow rate | 370L/h | 750L/h | 1500L/h |

| Cartridge Filter | 10 inch x 1 | 20 inch x 1 | 30 inch x 1 |

| Piping connection diameter | 20A | 20A | 25A |

| Power capacity (50/60Hz) | AC200V 180/216W | AC200V 180/216W | AC200V 180/216W |

| External dimensions: 2-tower type [width x depth x height] | 1,000×550×1,070mm | 1,140×550×1,070mm | 1,230×550×1,320mm |

| External dimensions: 3-tower type [width x depth x height] | 1,300×550×1,070mm | 1,500×550×1,070mm | 1,630×550×1,320mm |

| Model | W1P-2075LR/W1P-3075LR |

|---|---|

| Number of ion exchange towers | 2 tower type/3 tower type |

| Resin volume (L tower) | 75 |

| Maximum flow rate | 2000L/h |

| Cartridge Filter | 10 inch x 4 |

| Piping connection diameter | 25A |

| Power capacity (50/60Hz) | AC200V 750W |

| External dimensions: 2-tower type [width x depth x height] | 1,630×670×1,390mm |

| External dimensions: 3-tower type [width x depth x height] | 2,130×670×1,390mm |

*Ion exchange tower material: FRP, cartridge filter material: PPGF/PVC

*Standard accessories: Conductivity meter, pump switch, hose for connecting to ion exchange tower

*An activated carbon tower can also be installed as an option.

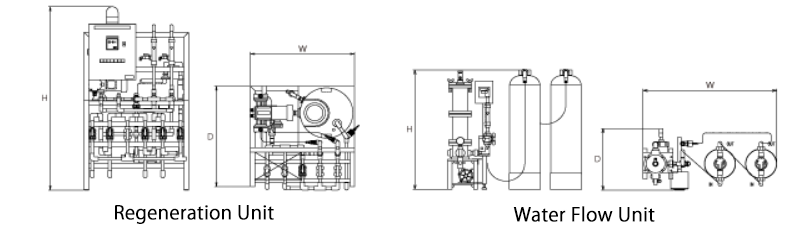

Drawing

Related Products

-

Sanshin New Sink YD type high performance coagulation and sedimentation equipment

-

Sanshin Pure water production equipment Econovac pure water production unit

-

Sanshin ECOACE® α Filter Cloth EAX Type E precision filter

-

Sanshin Patrone F Small MF membrane filtration device

-

Sanshin ECOACE® α EAX-S Stainless steel precision filter

-

Sanshin Integrated wastewater treatment system