Sanshu Sangyo

Sanshu Sangyo SK Series Greenhouse Heater

Manufacturer: Sanshu Sangyo Co., Ltd.

Model: SK Series

New touch-panel microcomputer box

1.Easy and convenient with touch operation

By adopting a newly developed color LCD touch panel, it has become easier to view and use.

Simple knob settings make operation straightforward.

2.Safe, Secure, and Energy-Saving

Next-generation “visible” energy-saving microcomputer boosts yield.

Provides reliable safety, security, and energy efficiency.

3.Equipped with a detachable controller

At the specified time, the blower or burner can operate regardless of the temperature.

Operation display screen (example)

Operation display screen (example)

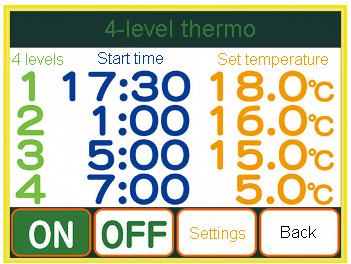

4-level thermo screen (example)

4-level thermo screen (example)

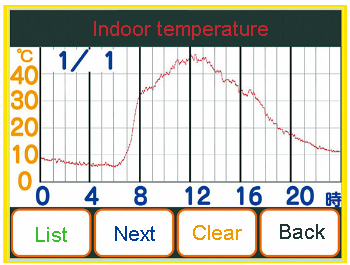

Indoor temperature graph screen (example)

Indoor temperature graph screen (example)

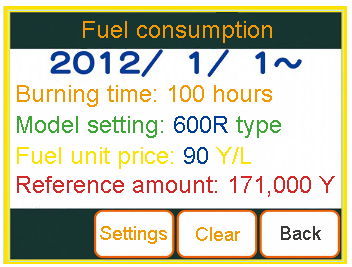

Fuel consumption screen (example)

Fuel consumption screen (example)

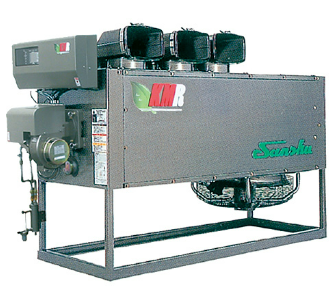

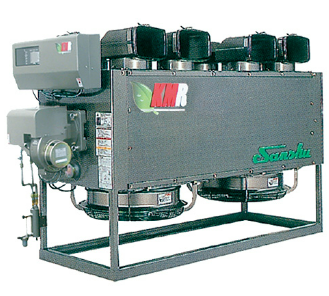

K M R Type

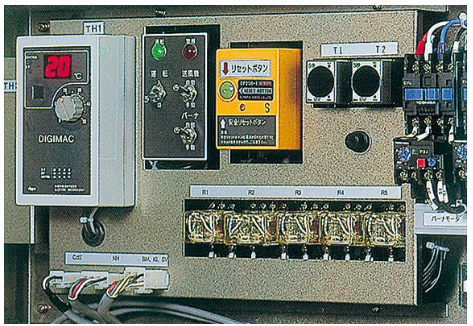

Microcomputer box

Microcomputer box

K A R Type

Analog box

Analog box

Durable furnace body (Almar treatment)

- New touch panel microcomputer

- Almar-treated furnace body

- Low-noise blower

- Adoption of a special spiral tube

- Easy duct attachment and removal with one-touch bands

- Newly developed service tank

- Burner

Down-blow type (DF model)

| SK-150KMR-UF | SK-200KMR-UF | SK-300KMR-UF |

|  |  |

| SK-400KMR-UF | SK-500KMR-UF | SK-600KMR-UF |

|  |  |

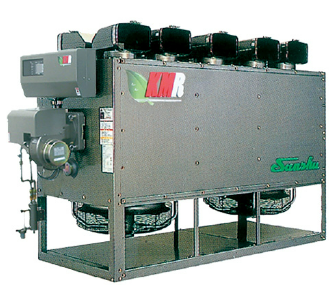

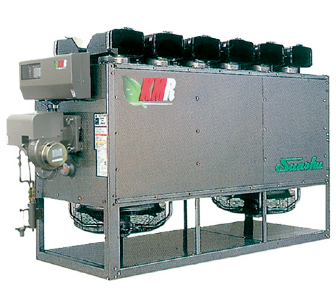

Low-floor type (T model)

| SK-500KTMR-DF | SK-600KTMR-DF |

|  |

| SK-700KTMR-DF | SK-800KTMR-DF |

|  |

Quick reference table for nozzle size and chimney size

| SK Model | Nozzle size | Chimney size |

|---|---|---|

| 110K | 085G/H 80° | Φ90 |

| 150K | 1,10G/H 80° | Φ150 |

| 200K | 1.35G/H 80° | |

| 300K | 2.00G/H 80° | |

| 400K | 2.75G/H 80° | Φ230 |

| 500K | 3,25G/H 80° | |

| 600K | 4.00G/H 80° | |

| 700K | 5.00G/H 80° | |

| 800K | 5.50G/H 80° |

Note:

① Please use the SS pattern from Hago Company for the nozzle size.

② Chimney size is in (mm) units.

Quick reference table for applicable ducts

| SK Model | Duct size | |||||

|---|---|---|---|---|---|---|

| Chamber type | Elbow type | |||||

| Main duct | Number of sub-ducts | |||||

| 400 | 450~475 | 550 | 630 | 450~475 | ||

| 110K | 400 | ― | ― | ― | ― | 2 |

| 150K | 630 | 6 | 4 | ― | ― | 3 |

| 200K | 8 | 6 | ― | ― | 4 | |

| 300K | 900 | 10 | 8 | 6 | 4 | 6 |

| 400K | 14 | 10 | 8 | 6 | 8 | |

| 500K | 1,100 | 20 | 14 | 10 | 8 | 10 |

| 600K | 24 | 20 | 14 | 10 | 12 | |

| 700K | 32 | 24 | 20 | 16 | ― | |

| 800K | ||||||

Note:

① Duct sizes are indicated by folded diameters (mm).

② The content of this table is for reference at the time of purchase. For details, please refer to the instruction manual or consult our sales office or agents.

Specification table

| SK Model | 150K | 200K | 300K | 300KT | 400K | 400KT | 500K | 500KT | 600K | 600KT | 700KT | 800KT | ||||||||

| Type | DF | UF | DF | UF | DF | UF | DF | DF | UF | DF | DF | UF | DF | DF | UF | DF | DF | DF | ||

| Heat output | kW | 44.2 | 58.1 | 872 | 116.3 | 1,453 | 1,744 | 2,093 | 232.6 | |||||||||||

| {kcal/h} | {38,000} | {50,000} | {75,000} | {1 00,000} | {125,000} | {150,000} | {180,000} | {200,000} | ||||||||||||

| Standard heating area | m² | 330〜495 | 495〜660 | 660〜990 | 990〜1,320 | 1,320—1,650 | 1,650〜1,980 | 1,980〜2,310 | 2,310〜2,640 | |||||||||||

| {Tsubo} | {100〜1 50} | {150〜200} | {200〜300} | {300〜400} | {400〜500} | {500〜600} | {600〜78} | {700〜88} | ||||||||||||

| Thermal efficiency | % | 90 | ||||||||||||||||||

| Burner | Electric motor | W | 150 | 250 | 400 | |||||||||||||||

| Fuel oil amount | ℓ/h | 4.8 | 6.4 | 9.5 | 12.6 | 15.8 | 19.0 | 22.8 | 25.3 | |||||||||||

| Fuel oil | 一 | Heavy oil type A | ||||||||||||||||||

| Nozzle heater | w | 50 | 250 | |||||||||||||||||

| Blower fan | Classi-fication | 一 | Pressurized blower fan | |||||||||||||||||

| Electric motor | w | 400 | 750 | |||||||||||||||||

| Base unit | Platform | 1 | 2 | 3 | ||||||||||||||||

| Airflow volume | m²/min | 63/74 | 82/96 | 110/125 | 1 70/200 | 250/290 | 330 | |||||||||||||

| Control device | Control method | — | Two-position (ON-OFF) control | |||||||||||||||||

| Ther- mostat | — | Thermistor type (M model: 〇〜35℃) adjustable / (A model: 〇〜50℃) adjustable | ||||||||||||||||||

| Safety device | — | ①Combustion safety control device②Overheat prevention device③Electric motor overload protection device④Blower fan timer⑤Hinge safety switch⑥Seismic sensor connection terminal | ||||||||||||||||||

| Poly duct folding width at exhaust outlet | mm | 630 X2 | 450 X3 | 630 X2 | 450 X4 | 900 X2 | 450 X6 | 900X2 | 450 X8 | 900 X2 | 1,100 X2 | 450 X10 | 1,100X2 | 450 X12 | 1,100X2 | |||||

| Chimney diameter | mm | 6,150 | 0230 | |||||||||||||||||

| Fuel pipe connection diameter | 一 | R3/4 | ||||||||||||||||||

| External dimensions | Overall width | mm | 760 | 950 | 1,070 | |||||||||||||||

| Overall length※1 | mm | 2,250 | 2,700 | 2,850 | 3,220 | 3,390 | 3,620 | |||||||||||||

| Overall height | mm | 1,500 | 1,560 | 1,500 | 1,540 | 1,480 | 1,140 | 1,500 | 1,480 | 1,140 | 1,820 | 1,760 | 1,420 | 1,820 | 1,760 | 1,420 | 1,620 | |||

| Electrical capacity | Single- phase S200V | Rated output (W) | 600 | 1,150 | — | |||||||||||||||

| Rated current (A) | 5.8/4 8 | 8.7/8.0 | 9.1 /8.0 | — | ||||||||||||||||

| HI02OOV | Rated output (W) | 600 | 1,150 | 1,900 | 2,000 | 2,900 | ||||||||||||||

| Rated current (A) | 3.8/3 8 | 6.7/6 3 | 10.6/9.9 | 11.5/10.6 | 14.0 | |||||||||||||||

| Effective heat transfer area | m² | 3.38 | 4.57 | 5.12 | 821 | 905 | 1,236 | |||||||||||||

| Total weight | kg | 290 | 295 | 355 | 330 | 385 | 370 | 600 | 570 | 520 | 630 | 600 | 550 | 685 | 690 | |||||

Note:

- The model codes indicate: DF type: Down-blow (Chamber), UF type: Up-blow (Elbow), KT type: Low-floor.

- There are also kerosene-only models available from 150 to 400K type (made to order).

- The nozzle heater capacity shows the nominal value.

- The dimensions marked with *1 include the burner and chimney elbow dimensions.

- The airflow value is based on a temperature of 20°C and no poly duct.

- The values represented by “/” in the specification table indicate the values for power frequency 50/60Hz, respectively.

- The SK-700KT and 800KT models are for 60Hz only (made to order).

- Thermal output and fuel consumption are calculated based on a specific gravity of 0.86kg/ℓ for A heavy oil and a lower heating value of 42.7MJ/kg (10,200kcal/kg).

- The specifications may be subject to change without notice for improvement purposes.

Kerosene-fired small heater

K Series

We propose clean combustion and fresh airflow for the Earth and crops.

SK-110KAⅡ-UF

SK-110KAⅡ-UF

SK-110KAⅡ-DF

SK-110KAⅡ-DF

All models have a thermal efficiency of 90%

Suitable for small greenhouses, poultry houses, cattle barns, pig pens, silkworm houses, mushroom cultivation,

Various seedling cultivation facilities, snow-melting systems, and more.

Specification table

| Model | SK-110KAⅡ-DF | SK-110KAⅡ-UF |

|---|---|---|

| Thermal output (kW) | 27.9 | 27.9 |

| Thermal output (kcal/h) | 24,000 | 24,000 |

| Standard heating area (㎡) | 330 | 330 |

| Standard heating area (tsubo) | 100 | 100 |

| Thermal efficiency (%) | 90 | 90 |

| Burner electric motor (W) | 20 | 20 |

| Fuel consumption (L/h) | 3.2 | 3.2 |

| Fuel used | White kerosene | White kerosene |

| Blower fan typev | Pressurized propeller fan | Pressurized propeller fan |

| Electric motor (W) | 200 | 200 |

| Airflow (m³/min) | 45 | 45 |

| Control device – Control method | Two-position (ON-OFF) control | Two-position (ON-OFF) control |

| Thermostat | Thermistor type (Adjustable from 0~50℃) | Thermistor type (Adjustable from 0~50℃) |

| Safety device | Combustion safety control device Overheat prevention device Blower fan timer Seismic sensor connection terminal | Combustion safety control device Overheat prevention device Blower fan timer Seismic sensor connection terminal |

| Fuel pipe connection diameter | R1/4 | R1/4 |

| External dimensions – Overall width (mm) | 780 | 780 |

| Overall length (mm) | 1,150 | 1,370 |

| Overall height (mm) | 1,150 | 1,590 |

| Rated power supply voltage (V) | Single-phase 100 | Single-phase 100V |

| Output (W) | 220 | 220 |

| Current (A) | 3.5 | 3.5 |

| Total weight (Kg) | 110 | 120 |

| Poly duct folding diameter at exhaust outlet (mm) | 400×2 locations | 400×2 locations |

| Chimney diameter (mm) | 90 | 90 |

- The model code indicates: DF type: Down-blow, UF type: Up-blow (Elbow).

- The overall length indicates the dimensions when the chimney elbow is installed.

- The overall height of SK-110KAⅡ-UF indicates the dimensions when the exhaust outlet elbow is installed.

- The generated heat amount is calculated based on the following values:

- <Kerosene> Lower heating value: 43.5MJ/kg {10400kcal/kg} Density: 0.8kg/cm3

- Airflow is the value at 20°C without poly duct.

- These specifications may be subject to change without notice for improvement purposes.

Waste oil mixed burner heater

Low-cost type greenhouse heater is born!!

Waste oil mixed burner heater – Proven excellent fuel savings!!

Specification table

| Model | SK-500B-DF | ||

|---|---|---|---|

| Thermal output | 145.3KW | ||

| 125,000kcal/h | |||

| Standard heating area | 1,650㎡ | ||

| 500坪 | |||

| Thermal efficiency | 90% | ||

| Burner | Electric motor | 250W | |

| Nozzle capacity | 3.25G/H | ||

| Blower fan | Electric motor | 750W | |

| Number of units | 2台 | ||

| Control device | System microcomputer | ||

| Poly duct folding diameter at exhaust outlet | 1,100mm | ||

| Chimney diameter | 230mm | ||

| External dimensions | Overall width | 1,060mm | |

| Overall length ※1 | 2,620mm | ||

| Overall height | 1,600mm | ||

| Electrical capacity | Three-phase 200V | Rated output | 4,000W |

| Rated current | 20A | ||

| Total weight | 650kg | ||

- The model code indicates: DF type: Down-blow (Chamber).

- The thermal output is calculated based on the oil density of 0.86kg/L and a lower heating value of 42.7MJ/kg (10,200kcal/kg).

- *The dimensions indicated in 1 include the burner and chimney elbow dimensions.

- These specifications may be subject to change without notice for improvement purposes.

High-tech WA burner

High-tech WA burner

Production area (Nagasaki Prefecture)

Production area (Nagasaki Prefecture)