Sanshu Sangyo

Sanshu Sangyo SP Series Automatic Dryer

Manufacturer: Sanshu Sangyo Co., Ltd.

Model: SP Series

Fully Automated Operation by Microcomputer

- Fully Automatic Drying with Basic Drying Program

- Humidity Priority – 4 items (monitors the moisture of the dry goods and ensures error-free drying)

- Time Priority – 4 items (performs drying according to the set program, based on the specified time)

- Custom Program Creation Available

- Programs can be created based on the operator’s preferences and can store up to three courses.

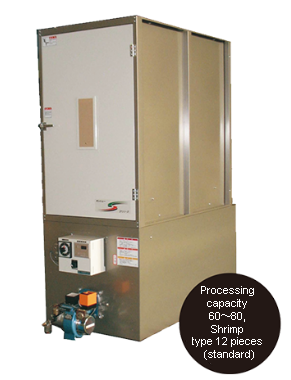

Small dryer

Panel: Made of steel plate

| SP-10K | SP-12K | DigiMac control box |

|  |  |

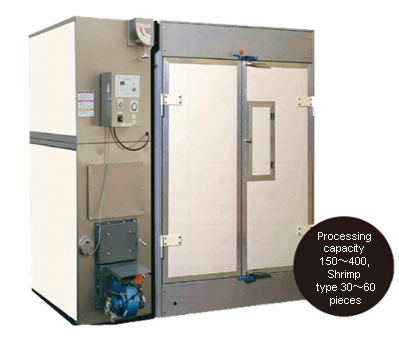

Fully automatic dryer

Panel: Rigid urethane foam insulation panel, 25mm thickness

| SP-15AT | SP-30AT | SP-45AT |

|  |  |

| SP-60AT | SP Microcomputer Control Box | |

|  |

Standard Type A Dryer

Panel: Rigid urethane foam insulation panel, 25mm thickness

| SP-15A | SP-30A | SP-45A |

|  |  |

| SP-60A | Standard control box | |

|  |

Wood and oil dual-purpose type

| SP-60AM | Standard control box |

|  |

Standard specifications

| Small dryer | Large dryer | New: Dual-purpose dryer for oil (Note 1) | ||||||||

| Model | SP-10K | SP-12K | SP-15A-AT | SP-30A-AT | SP-45A-AT | SP-60A-AT | SP-30AM | SP-45AM | SP-60AM | |

| Capacity (kg) | 3〇〜50 | 60〜80 | 75 〜1 00 | 150〜200 | 200〜300 | 300〜400 | 150〜200 | 200〜300 | 300〜400 | |

| Shrimp type | Number of pieces | 10 | 12(注) | 15 | 30 | 45 | 60 | 30 | 45 | 60 |

| Dimensions (mm) | 635X635 | 600X1,200 | ||||||||

| Blower motor output (W) | 25 | 100 | 250 | 400 | 750 | 250 | 400 | 750 | ||

| Burner | Model | GB-211 T | NK-1 0A | NK-1 0M | ||||||

| Fuel used | JIS1 No. Kerosene | JIS1 No. Kerosene (Note 5) | New Kerosene (JIS1 No.) | |||||||

| Fuel consumption (L/H) | 1.9 | 2.9 | 3.8 | 5.7 | 7.6 | 5.7 | 7.6 | |||

| Control device | Control method | Two-position ON-OFF control (Note 2) SP-AT uses microcontroller-based automatic program control (Note 3) | ||||||||

| Temperature controller | Thermistor type (with drying timer) ※The SP-AT model uses a Pt sensor | |||||||||

| Safety device | ①Combustion Safety Control Device (Protective Relay) ②Abnormal Overheating Prevention Device (Manual Reset Type) ③Burner Failure Alarm Buzzer | |||||||||

| Drying Room Material | Steel Plate Panel | Hard Urethane Foam Insulation Panel 25mm thick | ||||||||

| Chimney Diameter (mm) | ¢>90 | 6,130 | 6,150 | |||||||

| Dryer Dimensions | Overall Width (mm) | 920 | 606 | 1,245 | 1,900 | 2,550 | 3,250 | 2,020 | 2,660 | 3,370 |

| Depth (mm) | 680 | 1,390 | 1,280 | |||||||

| Overall Height (mm) | 1,800 | 1,830 | 1,950 (Note 4) | 2,100 (Note 4) | 2,100 | |||||

| Total Input Power (kw) | Single- phase 100V | 0.26 | 0.65 | 0.94 | 1.51 | 0.65 | 0.94 | — | ||

| Single- phase 200V | — | 1.51 | ||||||||

| Three- phase 200V | — | 1.41 | 1.41 | |||||||

(Notes)

- The firewood and oil mixed-use type is made to order.

- The SP-A model can be equipped with a 6-stage program controller as an option.

- The SP-AT model controls temperature, time, airflow, and circulation volume using SP microcontroller-based programming.

- The SP-15-60 AT requires a 400mm height space at the top of the drying room for the exhaust hood installation.

- The heavy oil specification is an option.

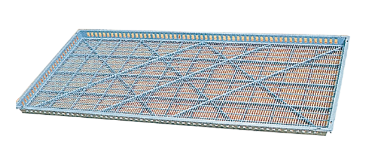

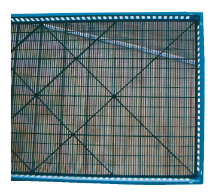

- The spacing of the Ebira shelves can be changed according to your preference with an option.

Note: This specification is subject to change without prior notice as part of ongoing improvements.

Custom Specifications

| Gas-Fired Method / Internal Stainless Steel (LPG) | SUS Trolley Method |

|  |

| Biomass Fuel Hot Water Utilization Method | Spot Air Distribution Method |

|  |

Option

| Standard Ebira 600×1200 | Slice-type fine mesh Ebira |

|  |

| 6-stage program controller | Seiro 7-2 type |

|  |

Exhaust gas booster (patent pending)

Depending on the installation location of the dryer, such as in areas with poor exhaust conditions, like longer horizontal runs of the chimney, the burner combustion is therefore stabilized, which in turn minimizes soot generation.

The installation can be done freely both vertically and horizontally, and it does not require a specific location.