Japan, SANWA TEKKI

Sanwa Tekki Variable Spring Hangers

Made in: Japan

Manufacturer: SANWA TEKKI

Model : Variable Spring Hangers

Variable Spring Hangers & In cases with highly flexible piping, evaluations are essential to verify that stress fluctuations caused by varying loads remain within the structural limits of the system. Allowable load variability is generally within 25% of the design load as described in MSS-SP-58. Assessments are necessary in situations where piping exhibits significant flexibility to ensure that fluctuations in stress resulting from load variations do not exceed the system’s structural limits.

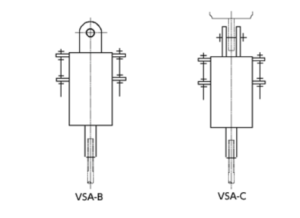

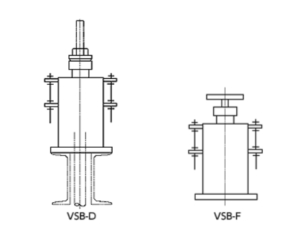

Standard Model & Type

(1) Suspension Types

(2) Floor Mount Types

Applicable Load and Travel Range

| Load Range | 0.059kN~248.89kN |

|---|---|

| Maximum Travel Range | 30mm~170mm |

Ranges of Load and Travel vary for each Travel Series (VS1, VS2, VSL2, VS4, VSL4) and Sizes (0~23).

For details, please see our Catalog No.2010 HUGR or contact our sales or engineering department.

Standard Design Features of STC Variable Spring Hangers are as follows:

- Following types are provided:

- Suspension Model & Type — Model VSA, Type B and C

- Floor Mount Model & Type — Model VSB, Type D and F

- A helical coil spring is pre-compressed and enclosed in the hanger casing to minimize its installation height and time of erection.

- The spring coils are easily visible for inspection through a full length opening on both sides of the casing.

- Extra travel is provided for each spring hanger & support at the upper and lower ends of the scale plate to allow for travel beyond the catalog limit.

- Each suspension type hanger (Type B and C) is equipped with a Turnbuckle for field adjustment of hanger rod length.

- Type F spring support is supplied with a Load Flange for pipe or pipe shoe mounting.

- Load-Travel Indicator is integral with Piston Plate.

- Applicable Load Ranges from 0.059kN to 248.89kN

- Maximum Travel for each Series

- VSA 1 — 30mm

- VSA 2 —– 60mm

- VSA L2 — 85mm

- VSA 4 — 120mm

- VSA L4 — 170mm

Related Products

-

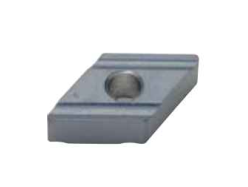

DIJET DNMG150404R-SG, DNMG150404L-SG, DNMG150408R-SG, DNMG150408L-SG Light To Medium Cutting Insert For Stainless Steel

-

Kyowa DBV-120A-4 120Ω gauge4-channel measurement Bridge Box Input Adapter

-

OSC 92TP121 Precision Digital Barometer

-

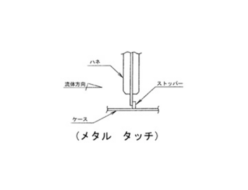

Toho Seisakusho Feather Seal Method

-

Saitamaseiki AK-551S Single Action and Double action Sanders

-

Kitz AKTAFM Floating Type 600 Brass Ball Valves (Full Bore)