Sasakura Engineering co,ltd.

SASAKURA Seawater Desalination Plant Rehabilitation Work

Manufacturer: Sasakura Engineering co,ltd.

Made In Japan.

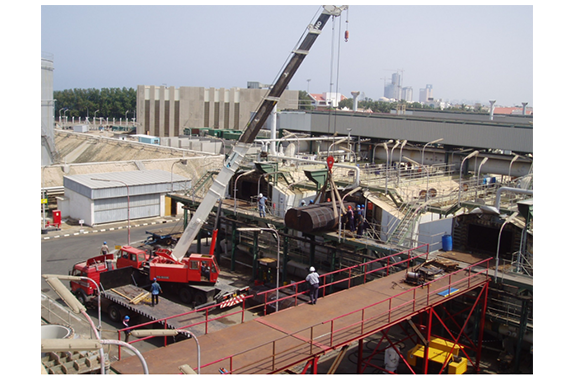

Product name: Seawater Desalination Plant Rehabilitation Work

Features

With the expertise in seawater desalination that Sasakura has accumulated over the years, we can repair not only our own plants but also those of other companies.

By repairing aging plants, we can extend the plant’s lifespan by another 15 years or more.

MSF · MED Rehabilitation

| 0 years | 20 years | 25 years | 35 years or more |

|---|---|---|---|

| Start of Operation | Rehabilitation Work | Life Extension by Rehabilitation (up to 15 years) possible | Total Plant Life: 35 years or more |

Rehabilitation Work Expenses

By utilizing the expertise Sazkla has established through rehabilitation work, it is possible to extend the life of existing plants at one-third of the cost of purchasing a new plant.

Existing Plant Existing Plant with Rehabilitation New Plant Initial Cost Y Y ± 33%~ 50% ± or =Y Construction Period Z < Z ± or =Z Plant Life 20 years + 15 years 20 years

Seawater Desalination Plant Rehabilitation Case Studies

The success of rehabilitation work at Sitra Phase 1 (Bahrain) has demonstrated that rehabilitation can significantly extend the plant’s lifespan at Sazkla. Sazkla has grown as a leading manufacturer in rehabilitation work, especially in the Middle East.

| Project Name | Scale | Unit Count | Equipment Type | Location | Start of Operation | Rehabilitation Year |

|---|---|---|---|---|---|---|

| Sitra (1st) | 22,700 tons/day | 1 unit | MSF | Bahrain | 1976 | 1987 |

| Sitra (1st) | 22,700 tons/day | 1 unit | MSF | Bahrain | 1976 | 2001 |

| BAPCO | 3,400 tons/day | 2 units | MSF | Bahrain | 1973 | 1996 |

| JEDDAH 4 | 227,100 tons/day | 10 units | MSF | Saudi Arabia | 1980 | 2005 |

| SEC Rabigh | 4,535 tons/day | 2 units | MSF | Saudi Arabia | 1983 | 2009 |

| Shoaiba 1 | 23,828 tons/day | 10 units | MSF | Saudi Arabia | 1988 | 2013 |

| Jubail C-4 | 23,500 tons/day | 10 units | MSF | Saudi Arabia | 1984 | 2015 |