Japan, Satuma Denki

Satuma Denki BRP2 (Disc type) AC operated DC Electromagnetic Brakes

Made in Japan

Manufacturer: Satuma

Model: BRP2

The BRP2 type AC-operated DC electromagnetic brake is a compact disc-type electromagnetic brake that is compatible with braking of motors with regenerative braking control such as inverters

Features

- A low-noise air damper with a small shock is standard equipment.

- An automatic adjustment system is used to adjust the upper and lower gaps of the brake lining.

Maintenance and inspection can be simplified. - Lubrication-free bushings are used for the main pins.

Oil-free use is possible in general indoor environments. - Sintered alloy is used for the brake lining material. It

exhibits stable braking force up to high temperatures without fading. - The brake (lining) has a symmetrical structure and

can be mounted on either side of the disc rotor.

(However, install the terminal box on the opposite side.)

1.Rating

*Table 1

| Brake type | BRP2 type AC operated DC electromagnetic brake |

| Actuation method | Non-excitation operation (instantaneous strong excitation type) |

| Application | Hoisting and traveling of cranes, industrial machinery (applied to motors with regenerative braking such as inverters) |

| Ambient temperature | -10°C to +40°C |

| Operating part protective structure | Dust-proof type (main body is unprotected type) |

| Operation part insulation type | Class B insulation |

| Rated voltage and rated frequency | 200V-50Hz, 220V-60Hz, 400V-50Hz, 440V-60Hz |

| Operation part usage rate | 60% |

| Number of operations of operation part | 400 times/hour |

| Paint color | Munsell 5B5/0.5 |

2.Specifications

*Table 2

| Brake type | Electromagnet Type | Control box Type | Braking torque (N • m) |

Disk rotor diameter (mm) |

Maximum emergency braking workload (kJ) | Maximum emergency braking rotational speed (min–1) Note 1 | |

| 30 m/s or less | 80m/s | ||||||

| BRP2- 180-1 | MD15D | BRD-SC | 150 ~ 240 | Φ 350 | 568 | 343 | 4300 |

|

175 ~ 280 |

Φ400 |

764 |

461 |

3800 | |||

| BRP2-180 |

270-395 |

Φ350 |

568 |

343 |

4300 |

||

| 310 – 460 | Φ400 | 764 |

461 |

3800 |

|||

| BAP2- 225- 1 | MD17D | BRD-SC | 410~ 610 | Φ400 | 764 | 461 | 3800 |

| 475~ 700 | Φ450 | 941 | 568 | 3300 | |||

| 540 ~ 790 | Φ500 | 1130 | 676 | 3000 | |||

| BRP2 · 225 | 625~ 885 | Φ400 |

764 |

461 |

3800 | ||

| 720 ~ 1020 | Φ450 | 941 | 568 | 3300 | |||

| 810 ~ 1150 | Φ500 | 1130 | 676 | 3000 | |||

| BRP2-280-1 | MD24D | BRD-SC | 920~ 1380 | Φ450 | 941 | 568 | 3300 |

| 1050 ~ 1580 | Φ500 | tt 30 | 676 | 3000 | |||

|

1310~ 1970 |

Φ600 |

1680 |

1010 |

2500 |

|||

| 1580 ~ 2370 | Φ700 | 2190 | 1310 | 2150 | |||

| BRP2·280 |

1410 ~ 1930 |

Φ450 |

941 |

568 |

3300 |

||

| 1610~ 2200 | Φ500 | 1130 | 676 | 3000 | |||

|

2010~ 2750 |

Φ600 |

1680 |

1010 |

2500 |

|||

| 2410~ 3300 | Φ700 | 2190 | 1310 | 2150 | |||

|

BRP2-355-1 |

MD29D | BRD-SC | 2230 ~ 3240 | Φ600 | 1680 | 1010 | 2500 |

| 2700~ 3920 | Φ700 | 2190 | 1310 | 2150 | |||

| 3170-~ 4590 | Φ800 | 2960 | 1770 | 1900 | |||

|

BRP2-355 |

MD31D | BAD-LC | 3610~ 5700 | Φ600 | 1680 | 1010 | 2500 |

| 4360-~ 6890 | Φ700 | 2190 | 1310 | 2150 | |||

| 5120~ 8080 | Φ800 | 2960 | 1770 | 1900 | |||

Note 1: Keep the normal braking rotational speed at approximately 1/10 of the maximum emergency braking rotational speed.

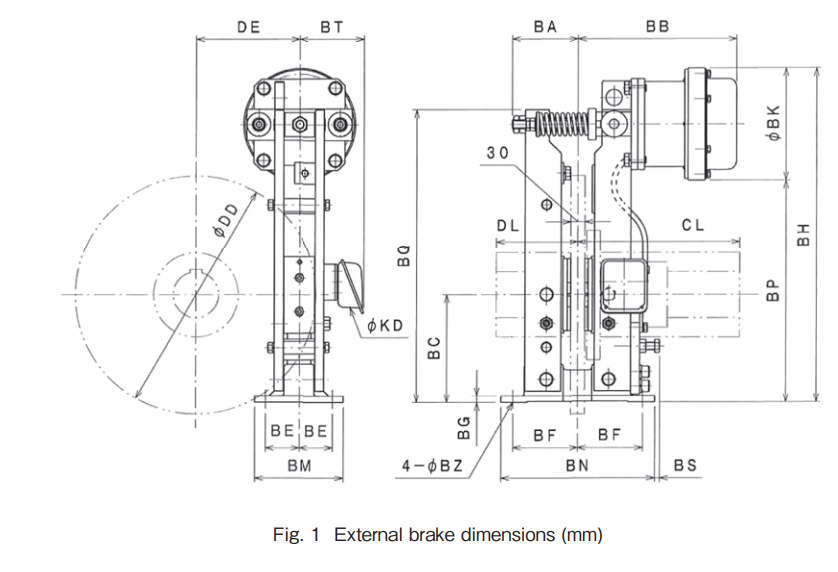

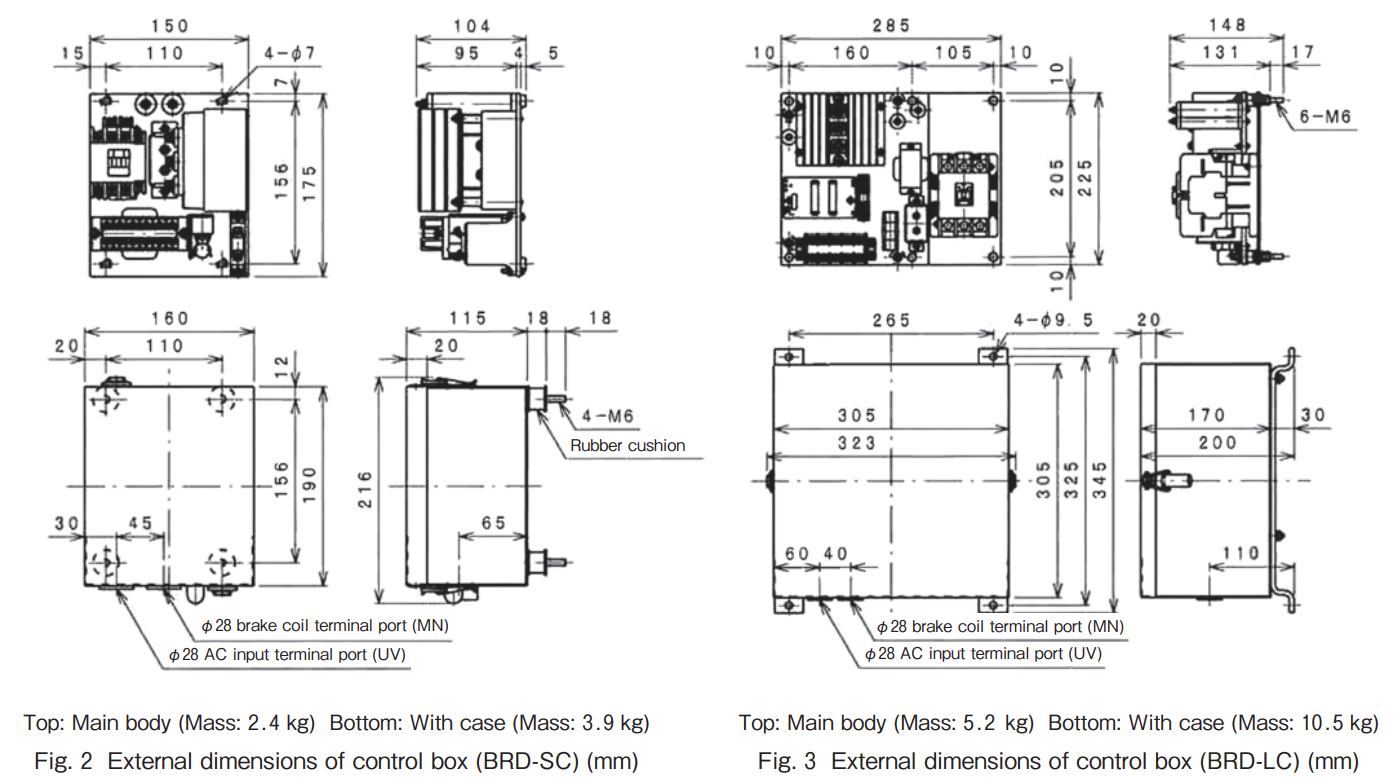

3. External dimensions

*Table 3 : External brake dimensions (mm)

|

Brake type

|

Brake main body (mm) | ||||||||||||||||

| FATHER | BB | BC | BG | BH | BP | BK | BQ | BEIGE | BF | BM | BN | BS | BZ | BT | KO | Weight (kg) |

|

| BRP2-180-1 BRP2-180 | 122 *145 |

292 | 180 | 13 | 563 | 350 | 213 | 481 | 60 | 115 | 150 | 260 | 11 | 15 | 125 | 28 | 55 |

| BRP2-225-1 BRP2-225 | 138 *160 |

328 | 225 | 14 | 699 | 465 | 234 | 612 | 70 | 135 | 185 | 320 | 0 | 24 | 135 | 28 | 85 |

| BRP2-280-1 BRP2-280 | 170 *185 |

341 | 280 | 22 | 863 | 557 | 306 | 745 | 75 | 160 | 200 | 370 | 8 | 28 | 150 | 28 | 175 |

| BRP2-355-1 | 213 *234 |

394 | 355 | 22 | 1076 | 714 | 362 | 935 | 100 | 210 | 270 | 490 | 0 | 35 | 194 | 34 | 330 |

| BRP2-355 | 213 *234 |

454 | 355 | 22 | 1086 | 704 | 382 | 935 | 100 | 210 | 270 | 490 | 0 | 35 | 194 | 34 | 375 |

*Dimensions marked with an asterisk (*) are those obtained when the brake lining has been worn, decreasing to the thickness limit.

*Table 4 : External disk rotor dimensions (mm)

| Brake Type | Disk rotor diameter | Effective radius | Disk rotor(standard) | Coupling-type disk rotor | ||||||

| ΦDD | DE | DL | J(kg・㎡) | Mass(kg) | DL | Cl | J(kg・㎡) | Transmitted torque(N・m) | Mass(kg) | |

| BRP2-180-1 BRP2-180 |

350 | 145 |

150 |

0.34 | 33 |

150 |

300 |

0.41 | 380 | 26/15 |

| 400 | 170 | 0.58 | 40 | 0.65 | 430 | 34/20 | ||||

|

BRP2-225-1 |

400 | 165 |

170 |

0.58 | 42 |

170 |

335 |

– | – | – |

| 450 | 190 | 0.95 | 53 | 1.17 | 1100 | 49/41 | ||||

| 500 | 215 | 1.43 | sixty seven | 1.60 | 1450/1490 | 58/45 | ||||

|

BRP2-280-1 |

450 | 175 |

200 |

0.95 | 57 |

200 |

350 |

– | – | – |

| 500 | 200 | 1.43 | 72 | – | – | – | ||||

| 600 | 250 | 3.00 | 103 | 3.25 | 2800 | 89176 | ||||

| 700 | 300 | 5.50 | 141 | 5.85 | 3400 | 115/85 | ||||

|

BRP2-355-1 |

600 | 240 |

240 |

3.00 | 104 |

240 |

400 |

– | – | – |

| 700 | 290 | 5.50 | 163 | 5.93 | 4500 | 123/108 | ||||

| 800 | 340 | 9.00 | 189 | 9.75 | 6800 | 171/165 | ||||

|

BRP2-355 |

600 | 240 |

240 |

3.00 | 104 |

240 |

465 |

– | – | – |

| 700 | 290 | 5.50 | 163 | 5.93 | 4500 | 123/108 | ||||

| 800 | 340 | 9.00 | 189 | 9.75 | 6800 | 171/165 | ||||

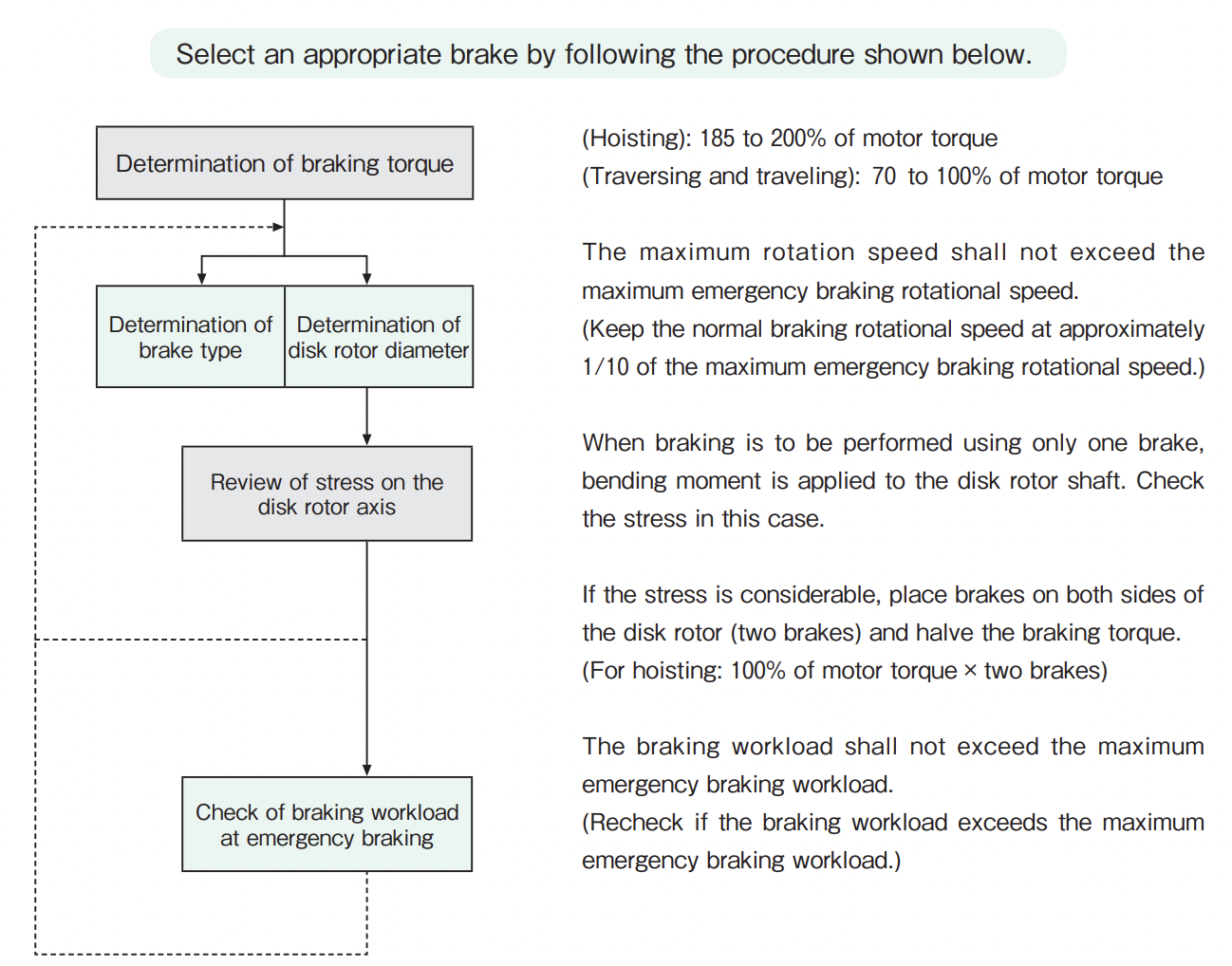

4. Selection

5. Installation site for the brake and disk rotor

Install a disk rotor on the direct-coupling side if the motor is of the bilateral-shaft type. (The disk rotor cannot be installed on the side of a self-cooling fan, in principle.

6. Face deflection of the disk rotor

Limit the face deflection of the disk rotor to 0.07 mm or less.

General expressions used for brake calculations

When ordering and making an inquiry Please inform us of the following:

1.Application: Crane type, classification (hoisting, traversing, and traveling), usage rate, Rating of operations (cycle/ hour), moment of inertia of the load

2.Operation environment: Indoor/outdoor use, ambient temperature

3.Brake type and Disk rotor diameter

4.Motor rating: Output/load hour rate, voltage, frequency (availability of inverter control regenerative braking)

5.Braking torque

6.Operation power supply: voltage, frequency

7.Spare parts

Related Products

-

TSURUMI PUMP PARTS: MECHANICAL SEAL 2OM 2PU Parts & Accessories

-

KONAN NC211 2-port Solenoid Valves For Nuclear Power Plants Normally Closed

-

Tsugaru Kogyo No.2012 Agricultural 42.7 Single Clamp

-

Kanetec PCMH2-E20 Sanitary Type Magnetic Filter For Viscous Liquids

-

KANSAI RS Lightweight Shackle

-

IMADA PSH series High load Type Mechanical Force Gauge