Japan, Seishin

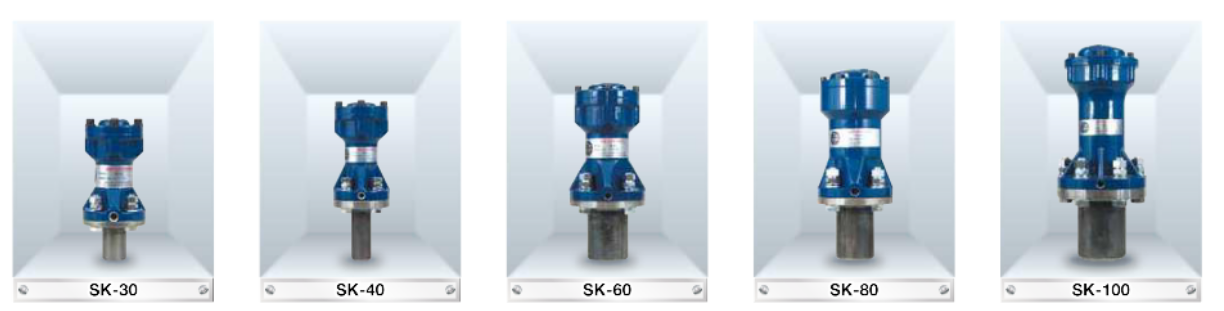

Seishin SK Series Air-Knocker

Made in Japan

Manufacturer: Seishin

Model: SK Series: SK-30, SK-40, SK-60, SK-80, SK-100

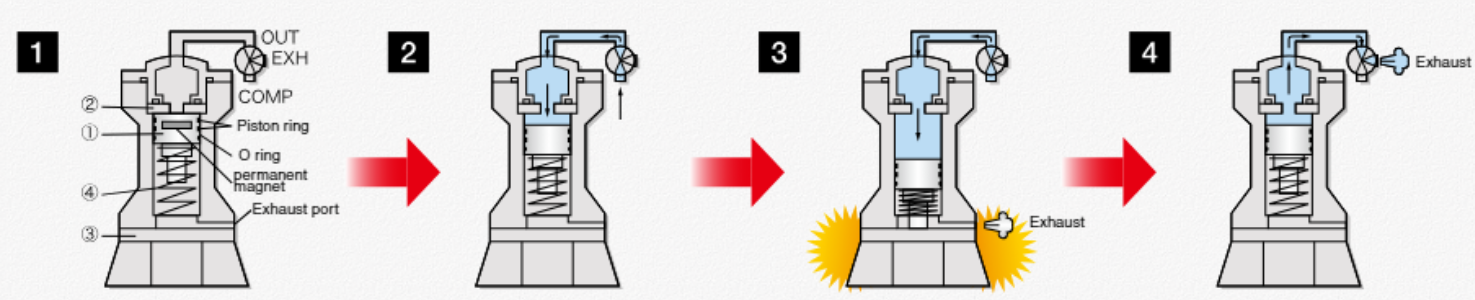

Air knocker SK type operation principle

- When air pressure is not infused into the cylinder from the three-phase solenoid valve, the magnetic piston① attaches the Anchor plate② firmly.

- Turn on the switch to electrify the Three-phase solenoid valve. When air pressure becomes enough to detach the Magnetic piston from the Anchor plate, the Magnetic piston hits the Base plate③ with a high velocity.

- The Base plate indirectly transmits a shock to the inside of a hopper, which breaks down the bridge or formation of powder in the hopper.

- Tunr off the swith and the compressed air remaining in the Cylinder is exhaus -eted through the three-phase solenoid valve. The Magnetic piston is replaced by the Return spring④

Alminium casting Alminium casting Alminium casting ※Total weight includes weight of base bolt and base plate. Paint color : Mancell5PB3/9

Please attach the Airknocker SK type to the base plate and operate it. If it is operated only with the main body, the inside may be damaged. Fall prevention wire is optional, but please be sure to install it. Please attach reinforcing ribs referring to

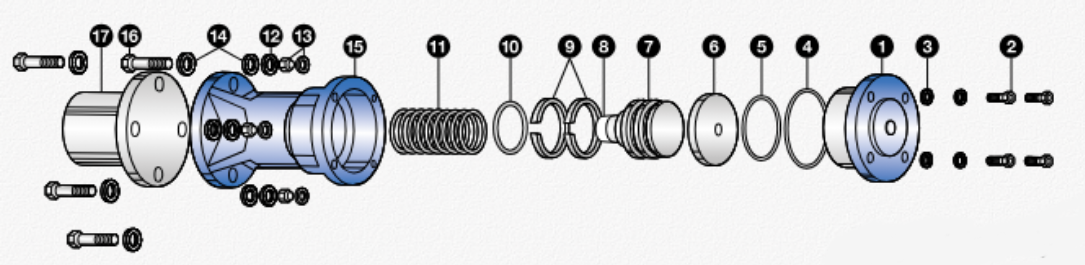

Part drawing of Air knocker SK type and part names

- Head Flang

- Bolt with Hexagonal Hole

- Washer

- O ring for Head Flange

- O ring for Anchor plate (SK80 and 100 use gasket)

- Anchor plate

- Magnetic Piton

- Point Bush

- Piston Ring

- O ring for Piston

- Return Spring

- Spring Washer

- Hard Lock Nut

- Washer

- Main Body

- Base Bolt

- Base Plate

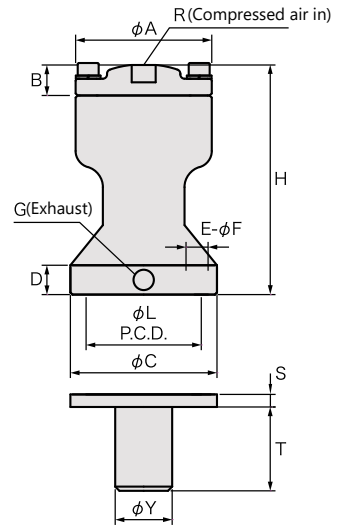

Specification

| Specification | Model | SK-30 | SK-40 | SK-60 | SK-80 | SK-100 |

| Pressure (MPa) | 0.35~0.6 | 0.35~0.6 | 0.35~0.6 | 0.35~0.6 | 0.35~0.6 | |

| Air consumption (l/time) | 0.028 | 0.082 | 0.228 | 0.455 | 1.012 | |

| Impact Power (Ns) | 1.0~1.5 | 3.3~5.1 | 7.1~10.8 | 19.3~29.5 | 44.5~67.9 | |

| Body Weight (kg) | 0.7 | 1.8 | 4.6 | 7.9 | 23.5 | |

| Total Weight (kg) | 1 | 2.9 | 7.8 | 11.8 | 35.2 | |

| Body Material | Alminium Casting | Alminium Casting | Alminium Casting | Alminium Casting | Casting Iron | |

| Dimension | øA | 65 | 90 | 120 | 139 | 176 |

| B | 15 | 22 | 30 | 40 | 44 | |

| øC | 70 | 95 | 140 | 150 | 210 | |

| D | 10 | 16 | 16 | 18 | 24 | |

| E | 4 | 4 | 4 | 4 | 6 | |

| F | 9 | 11 | 15 | 17 | 21 | |

| G | 1/8 | 1/8 | 1/4 | 3/8 | 3/8 | |

| H | 110 | 160 | 210 | 250 | 328 | |

| øL | 55 | 70 | 110 | 120 | 170 | |

| S | 6 | 12 | 12 | 14 | 22 | |

| T | 40 | 90 | 100 | 110 | 145 | |

| øY | 27.2 | 34.0 | 76.3 | 76.3 | 114.3 | |

| R | 1/4 | 1/4 | 1/4 | 3/8 | 3/8 |

Related Products

-

Kuken VAV/CAV

-

Ross Asia High Capacitance Series Remote Pilot Resistor Port size from 3/4″ to 2″. Flow rates up to 4000 scfm (113280 l/min)

-

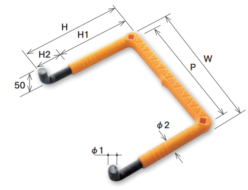

Flex System L-Shaped Amenity Step (Pre-Attached, Field Type)

-

HANKOKU AQN Motor Siren (Single Phase)

-

Watanabe WVP-AZ AC converter – Signal Converter

-

Tosei Sharyo TY, TY-N Series Two Wheels