Japan, ShinMaywa

ShinMaywa CN/CN-MT/CNH Series Submersible Pumps

Product Made in Japan

Manufacturer: ShinMaywa Industries, Ltd.

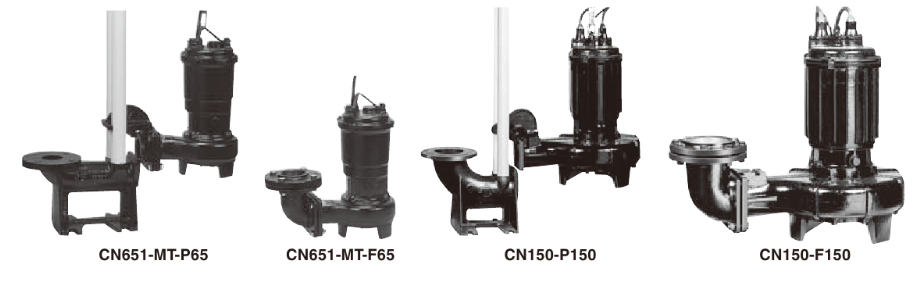

Model: CN/CN-MT/CNH Series

Non-Clog Channel Type

<Discharge size> 40~150mm

<Rated output> 0.25~22kW

<Phase > 3

Suitable for transfer and discharge of Sludge at sewage treatment plant

Standard Specifications

| Discharge (mm) | Pump model | Installation kit No. | Rated output (kW) | No. of poles | Flow-Total head (m7min-m) | Solid passage dia. (Soft solid) (mm) | Pump weight (kg) | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Guide rail installation | Free standing | |||||||||

| 50Hz | 60Hz | 50Hz | 60Hz | |||||||

| 40 | CN401T-MT | P40 | F40 | 0.25 | 2 | 0.1 -5.5 | 0.1 -5.5 | 21 | 20 | 17 |

| 50 | CN501T-MT | P50 | F50 | 0.4 | 2 | 0.15-6.0 | 0.15-6.0 | 28 | 24 | 17 |

| CN501-MT | 0.75 | 0.2 -8.2 | 0.2 -7.5 | 30 | 29 | 18 | ||||

| 65 | CN501T-MT | P65B | F65B | 0.4 | 2 | 0.15-6.0 | 0.15 -6.0 | 28 | 24 | 17 |

| CN501-MT | 0.75 | 0.2 -8.2 | 0.2 -7.5 | 30 | 29 | 18 | ||||

| CN651-MT | P65 | F65 | 1.5 | 0.4 -10.6 | 0.4 -10.0 | 41 | 33 | 29 | ||

| CN80-MT | 2.2 | 4 | 0.8 -8.4 | 0.8 -8.6 | 54 | 51 | 58 | |||

| 3.7 | [1] 1.0 -1 [3] 0.8 -14.4 | 1.0 -11.8 | 53 | 54 | 70 | |||||

| 80 | CN651-MT | P80 | F80 | 1.5 | 2 | 0.4 -10.6 | 0.4 -10.0 | 41 | 33 | 29 |

| CN80-MT | P80B | 2.2 | 4 | 0.8 -8.4 | 0.8 -8.6 | 54 | 51 | 58 | ||

| 3.7 | [1] 1.0 -11.8 [3] 0.8 -14.4 | 1.0 -11.8 | 53 | 54 | 70 | |||||

| CN100-MT | 5.5 | [1]1.2 -12.9 | [2]1.2 -13.6 | 60 | 53 | 95 | ||||

| [3] 0.9 -18.0 | [4]0.9 -18.0 | 54 | ||||||||

| 7.5 | [1] 1.4 -15.2 | [2]1.4 -16.7 | 60 | 53 | 108 | |||||

| [3] 1.0 -21.8 | [4]1.0 -22.5 | 60 | ||||||||

| 100 | CN80-MT | P100B | F100 | 2.2 | 4 | 0.8 -8.4 | 0.8 -8.6 | 54 | 51 | 58 |

| 3.7 | [1] 1.0 -11.8 [3] 0.8 -14.4 | 1.0 -11.8 | 53 | 54 | 70 | |||||

| CN100-MT | 5.5 | [1] 1.2 -12.9 | [2]1.2 -13.6 | 60 | 53 | 95 | ||||

| [3] 0.9 -18.0 | [4]0.9 -18.0 | 54 | ||||||||

| 7.5 | [1] 1.4 -15.2 | [2]1.4 -16.7 | 60 | 53 | 108 | |||||

| [3] 1.0 -21.8 | [4]1.0 -22.5 | 60 | ||||||||

| CNH100 | P100C | F100B | 11 | 1.57 -22 | 1.58-22 | 54 | 54 | 216 | ||

| 15 | 1.9 -26 | 1.86-26 | 54 | 55 | 230 | |||||

| 22 | 1.8 -35 | 1.96 -35 | 55 | 58 | 290 | |||||

| 150 | CN150-MT | P150 | F150 | 5.5 | 4 | 2.0 -10 | 1.96-10 | 70 | 65 | 122 |

| 7.5 | 2.48-12 | 2.33-12 | 75 | 70 | 134 | |||||

| CN150 | 11 | 2.54-16 | 2.6 -16 | 64 | 57 | 215 | ||||

| 15 | 2.87-19 | 3.0 -19 | 70 | 62 | 228 | |||||

| 22 | 3.6 -22 | 3.86 -22 | 76 | 67 | 326 | |||||

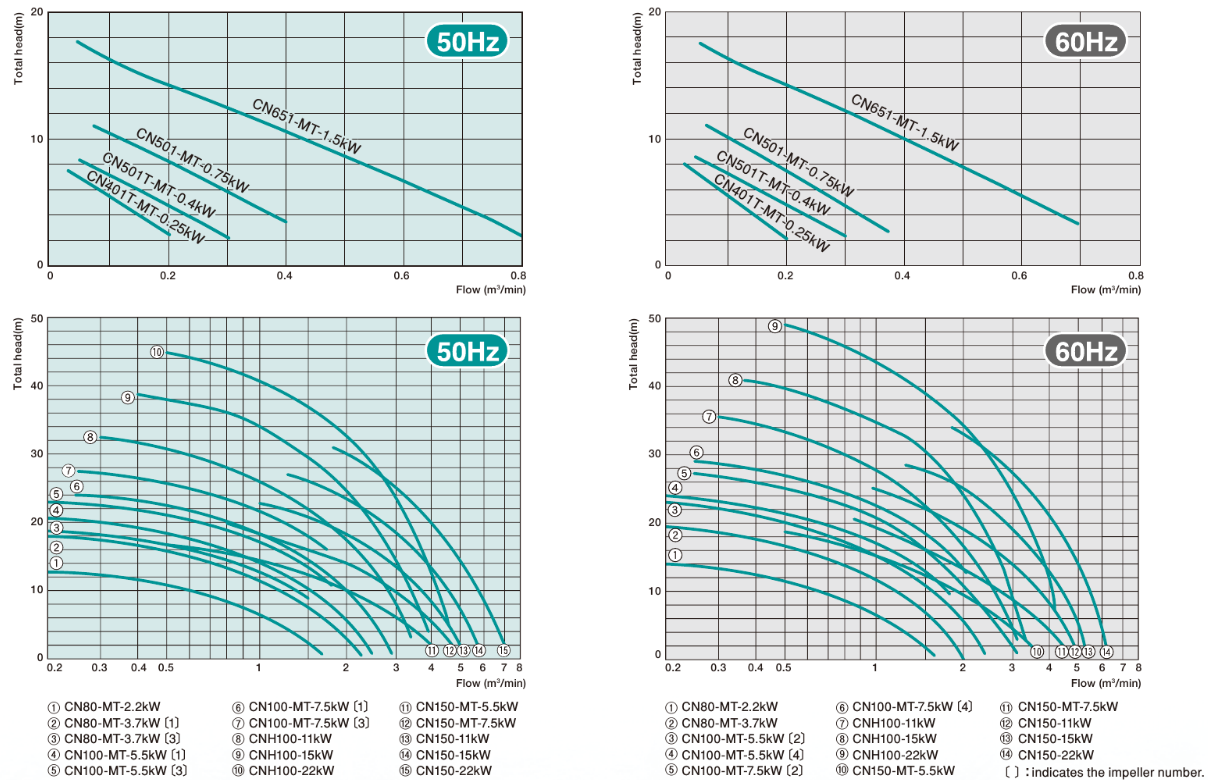

“The starting method is direct-on-line for 7.5 kW or less and star-delta for 11 kW and over. () indicates the impeller number. Note: Please inform us of the pump model and installation kit number.

Performance Curves

Features

- Cable entry with core wire seal

The core wire seal shuts the watar out from penetrating into the motor through the core wire. - Motor protector

Thermal protector (a built-in automatic reset type motor protector) or thermal switches are embedded to the motor winding. - Air-filled submersible motor

- Shaft seal

A highly wear resistant double mechanical seal is employed. Besides, combined use of an oil seal further extends the life. (except for some models) - Discharge connection

The system automatically connects the pump to the discharge pipe. - Impeller

The factory fully adjusts the solid handling type channel impellers to the dynamic/static balance.

Standard Accessories

Cable (7.5kW or less): 1pc 6m for 0.75kW or less

Cable (11kW or more): 3pcs 8m for 1.5kW or more

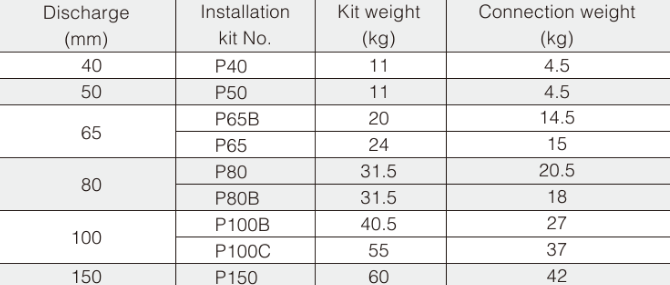

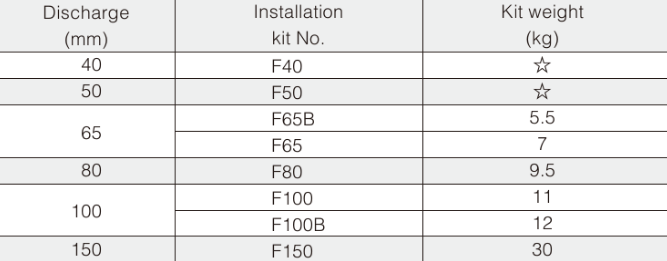

Guide Rail Installation Kit

- Discharge connection

- Guide holder (with bolts and nuts)

- Sliding bracket

- Lifting chain (6m)

Free Standing Kit

- Discharge flange

- Companion flange (with bolts, nuts and gasket)

*Built into the pump.

Applications

- Treatment processes at onsite wastewater treatment systems

- Treatment processes at sewage-treatment plants and night-soil treatment plants

- Pumping stations in the sewerage / wastewater collection system

- As sanitary equipment for effluent from building facilities

- Draining stormwater from roads or underpass

- Treatment processes at industrial wastewater treatment facilities

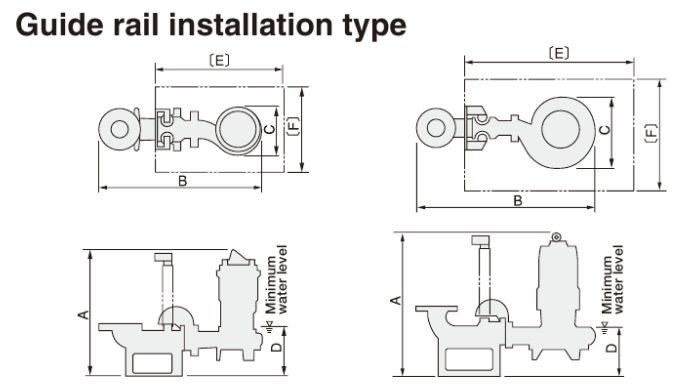

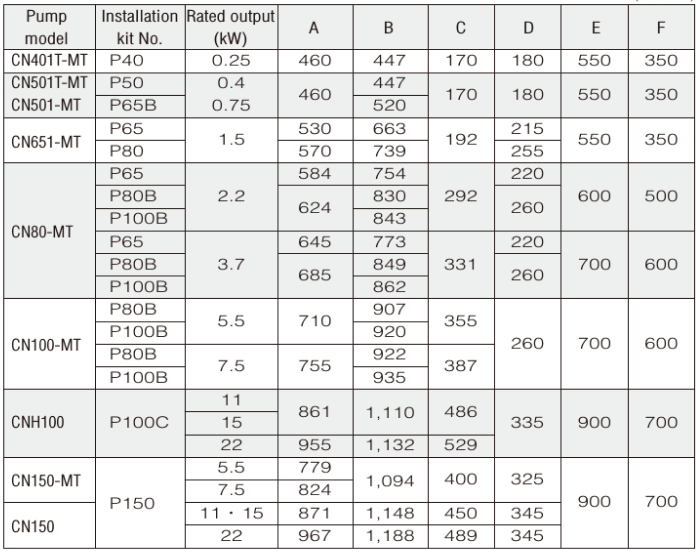

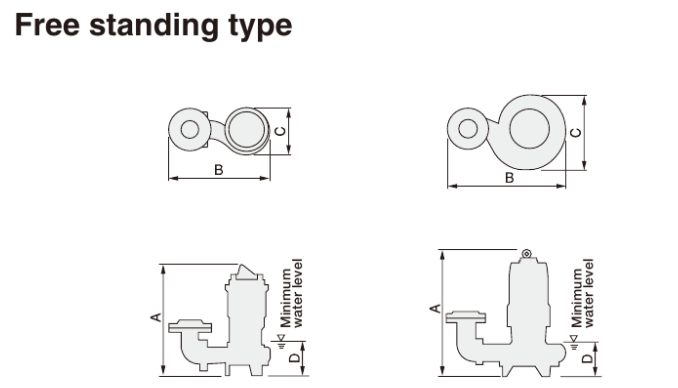

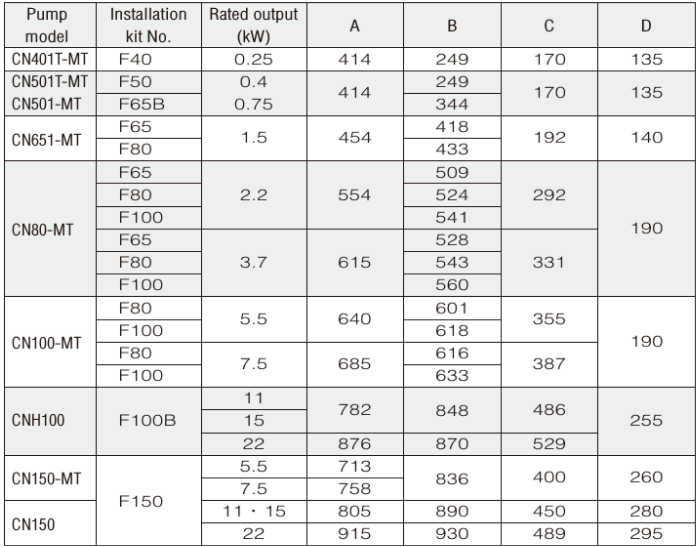

Dimensions

Unit: mm