Showa Kikai Shoji

Showa Kikai Shoji Pressure Casting Machine

Made in Japan

Manufacturer: Showa Kikai Shoji

Features of our products

High reliability

Induction heating technology is widely used across various industries due to its excellent characteristics, such as high heating efficiency, high reliability, and the realization of a clean working environment.

SKS’s high-frequency power supply has achieved technological innovation by responding to numerous requests from customers and sites, resulting in high performance, high quality, and low prices. It is adopted for various applications according to needs.

Frequency and output

| Output | 2.5kw 〜 40kw |

|---|---|

| Frequency | 50 KHz ( 30 〜 60 KHz) 100 KHz ( 60 〜 120 KHz) 200 KHz (120 〜 240 KHz) 400 KHz (240 〜 440 KHz) |

The oscillation frequency and output provided are guidelines. Depending on the type and shape of the heated object (workpiece) and the specifications of the heating coil, custom designs are possible.

Pressure casting machine

This pressure casting machine melts precious metals such as gold, silver, and WG in a vacuum or inert gas atmosphere and drops the molten metal into the mold (injected under pressure). It allows for various casting modes, such as vacuum suction in the mold chamber simultaneous with pressurization.

| Device Model | SVP – 1015NV |

|---|---|

| High frequency output / Frequency | 10Kw / 100KHz ±10% |

| Casting (melting) quantity | Au 1500g / Ag 800g Max (Standard crucible specification) |

| Power supply | 3-phase 200/220V, 50/60Hz, 16KVA |

| Mold dimensions | φ114×200(250)H Max |

| Temperature measurement method | Thermocouple (K: 0 to 1200°C / R: 0 to 1500°C) |

| Casting atmosphere | Atmosphere / Vacuum / Inert gas (replacement) atmosphere |

| Centrifugal motor / Rotational speed | Vacuum / Pressurized / Vacuum (mold chamber suction) pressurized |

| Vacuum pump (Belt-driven type) | Oil rotary vacuum pump / Exhaust speed 300 L/min |

| Cooling | Water-cooled type (Water pressure 0.15 MPa / Water flow rate of 10 L/min or more) |

| External dimensions / Weight | 880W×750D×1450H / 200kg |

- The high-frequency output features a standard 10 kW power supply designed for a carbon crucible load, but custom designs can be created based on your budget and requirements.

- It is equipped with a semi-automatic operating mode that allows for manual adjustment of heating output during automatic operation, as well as various manual operations such as pouring at any timing, starting pressurization, and injecting inert gas.

High-frequency vacuum suction and pressure casting machine

Related Products

-

Showa Kikai Shoji HDT106A 1000kN Servo Valve-Type Hydraulic Fatigue Testing Machine

-

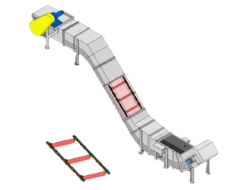

Showa Kikai Shoji Chainring

-

Showa Kikai Shoji Chain (Without Heat Treatment) With Strength Guarantee

-

Showa Kikai Shoji Scraper Conveyor

-

Showa Kikai Shoji Conveyor Chain

-

Showa Kikai Shoji W Series Sprocket Wheel For Conveyor