Showa Co.

Showa Plate Type Heat Exchanger

Made in Japan

Manufacturer: Showa Co., Ltd

Plate Type Heat Exchanger

This type of heat exchanger consists of many corrugated plates and the hot and cold fluids alternate between each of the plates.

The most distinctive feature of plate type heat exchanger is that you can increase or decrease the number of plates. In other words, you can increase or decrease the capacity.

As for the plate material, titanium is mainly used for seawater type.

Stainless can be also used.

In case of heat exchanger on ship, due to the limited space on ship, plate type heat exchanger is more likely to be adopted.

Our company decided to become an all-round player in the field of heat exchangers, so we are now able to supply products and services for all types including shell & tube type, fin type and plate type.

Photo below is our first plate type heat exchanger.

This is relatively small, but the structure is the same for larger type.

This is the product appearance. Numbers of heat exchange plates are sandwiched by both rear and front plates.

There are 4 inlets and outlets for cooling and being cooled.

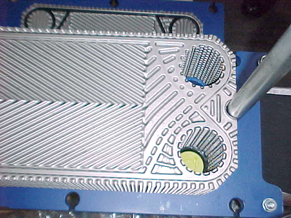

You can see the plate shape. This corrugated shape enhances thermal efficiency and strength of plates.

You can see the plate shape. This corrugated shape enhances thermal efficiency and strength of plates.

The fluids to cool and the fluids to be cooled alternate between front and back side of the plates.

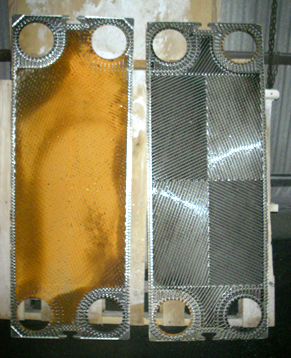

These plates were used for long time. The left plate is before cleaning and the right is after cleaning.

These plates were used for long time. The left plate is before cleaning and the right is after cleaning.

Such high level of dirt affects performance.

Usually, NBR is used for seal gasket between each plate.

NBR’s material has improved, so it has good sealability and deterioration resistance.

Installation of Plate Type Heat Exchanger

After plate type heat exchanger is delivered to the site, we start to work on installation.

It is made by piling up many thin plates, so we have to handle it with the utmost care, especially when lifting.

If any unnatural force is imposed, it could cause liquid leak.

After installed properly, we connect pipe to the part for cooling and the part for being cooled.

To be more specific, there are many other works to be done, but basically above is the brief description of the installation

After installation, next is running. We have to be careful here again.

This is what all heat exchangers have in common, but firstly the cold fluids should be flowed in and then the hot fluids. If you reverse this order, it will cause troubles.

Most customers do installation by themselves and they are well aware of procedures,

so we rarely encounter any troubles on installation or first running.

Photo below shows piping for the plate type heat exchanger which cools lubricating oil.

There are 150 plates in this heat exchanger.

It is under piping.

These are the plates before assembly.Since it is for ship, those plates are delivered near the equipment onboard.

We have to be careful not to impose unnatural force when piping and it requires a great deal of skilled techniques.