Simotec

Simotec Neodymium Magnet

Manufacturer: Shimonishi Giken Kogyo Co., Ltd

Product name: Neodymium Magnet

Features

- Neodymium magnets are primarily compose of neodymium, iron, and boron, and have the best magnetic properties of any magnet currently available.

- Neodymium magnets are a representative rare earth magnet, and are characterize by their stronger adhesive power than other magnets.

- Even when make smaller, satisfactory suction power can obtain, so it can fully meet the demand for downsizing.

- While it has excellent mechanical strength, it is not suitable for high temperatures.

- – Because it is prone to rust, it is plate to prevent rust.

Purpose of use

・Motors, sensors, precision machinery, etc.

Specification

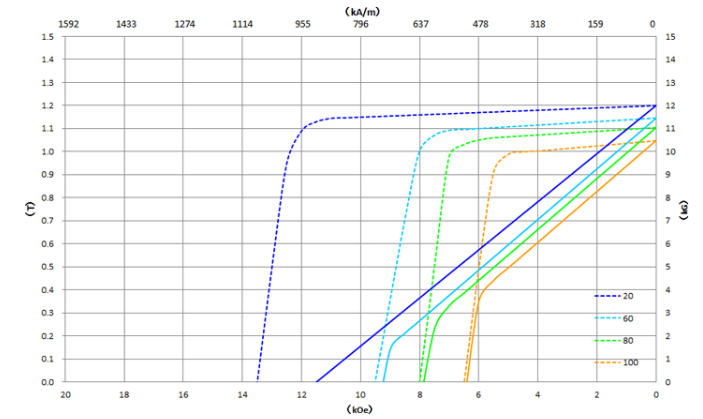

Neodymium magnet N35: Comparison of demagnetization curves due to temperature difference

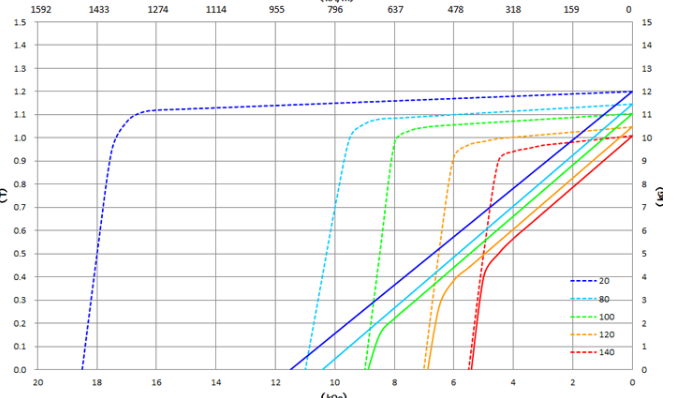

N35H: Comparison of demagnetization curves due to temperature difference

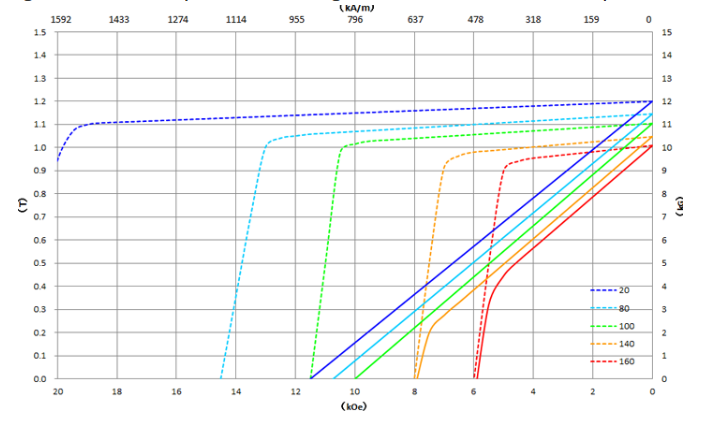

N35SH: Comparison of demagnetization curves due to temperature difference

Neodymium magnetic properties

| Material Grade | Residual magnetic flux density (Br) | Coercive force (Hcb) | Coercive force (Hcj) | Maximum energy product (BH) max | Temperature coefficient (αBr) | Working Temp | Curie Temperature | ||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| kg | mT | kOe | kA/m | kOe | kA/m | MGOe | kJ/m3 | %/℃ | °C (H/D =0.7) | °C | |

| 35 | 11.7-12.2 | 1170-1220 | 10.8-11.4 | 860-907 | ≧12 | ≧955 | 33-36 | 263-287 | -0.12 | ≦80 | 310 |

| 42 | 13.0-13.6 | 1300-1360 | 11.7-13.1 | 931-1043 | ≧14 | ≧1114 | 40-44 | 318-350 | -0.12 | ≦80 | 310 |

| 50 | 14.0-14.4 | 1400-1440 | 12.9-14.1 | 1026-1122 | ≧14 | ≧1114 | 47-51 | 374-406 | -0.12 | ≦80 | 310 |

| 35H | 11.7-12.2 | 1170-1220 | 10.8-11.4 | 860-907 | ≧17 | ≧1353 | 33-36 | 263-287 | -0.11 | ≦120 | 340 |

| 40H | 12.7-13.3 | 1270-1330 | 11.5-12.9 | 915-1027 | ≧17 | ≧1353 | 38-42 | 302-334 | -0.11 | ≦120 | 340 |

| 41H | 10.8-11.0 | 1270-1330 | 11.5-12.9 | 915-1027 | ≧17 | ≧1353 | 38-42 | 302-334 | -0.11 | ≦120 | 340 |

| 44H | 13.3-13.9 | 1330-1390 | 11.9-13.3 | 947-1056 | ≧17 | ≧1353 | 42-46 | 334-366 | -0.11 | ≦120 | 340 |

| 47H | 13.7-14.1 | 1370-1410 | 12.8-14.0 | 1019-1115 | ≧16 | ≧1273 | 45-49 | 358-390 | -0.11 | ≦120 | 340 |

| 35SH | 11.7-12.2 | 1170-1220 | 10.8-11.4 | 860-907 | ≧20 | ≧1592 | 33-36 | 263-287 | -0.10 | ≦150 | 340 |

| 42SH | 12.7-13.3 | 1270-1330 | 11.6-13.0 | 923-1035 | ≧21 | ≧1671 | 39-43 | 310-342 | -0.10 | ≦150 | 340 |

| 45SH | 13.3-13.9 | 1330-1390 | 12.5-13.9 | 995-1107 | ≧21 | ≧1671 | 43-47 | 341-373 | -0.10 | ≦150 | 340 |

| 35UH | 11.7-12.3 | 1170-1230 | 10.9-12.3 | 867-979 | ≧30 | ≧2388 | 32-36 | 255-287 | -0.10 | ≦180 | 350 |

| 38UH | 12.3-12.9 | 1230-1290 | 11.4-12.8 | 907-1019 | ≧25 | ≧1990 | 35-39 | 278-310 | -0.10 | ≦180 | 350 |

| 40UH | 12.6-13.2 | 1260-1320 | 11.5-13.2 | 939-1051 | ≧25 | ≧1990 | 37-41 | 294-326 | -0.10 | ≦180 | 350 |