Suntes

Suntes Structure and operating principle

Manufacture: Suntes (Sanyo Shoji Co., Ltd.)

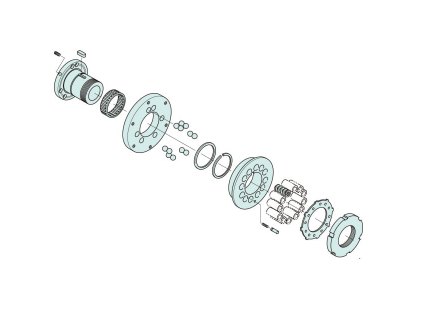

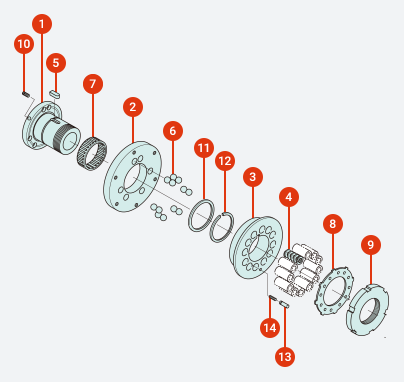

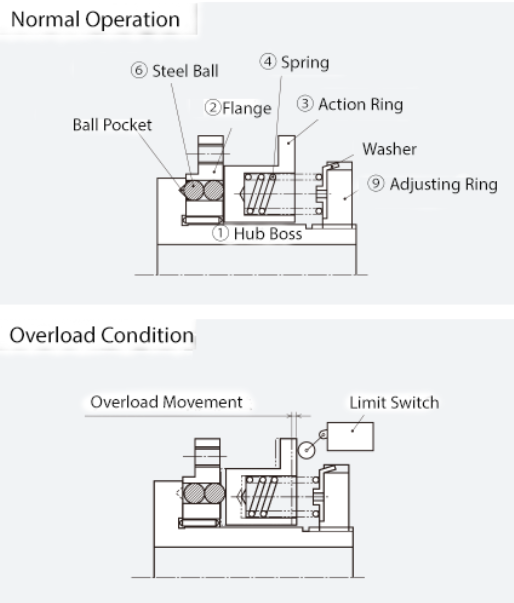

Part Names

- Hub Boss

- Flanges

- Action Ring

- Spring

- key

- Steel ball

- bearing

- Washer

- Adjustable Ring

- Hexagonal Socket Set Screw

- ring

- WR type retaining ring

- pin

- Spring

Operation

- During normal operation, the steel ball ⑥ held by the flange ② is pressurized and held in the ball pocket of the hub boss ① by the force of the spring ④, and torque is transmitted from the hub boss ① to the flange ② via the steel ball ⑥.

- In the event of an overload, the steel ball ⑥ is pushed out by the slope of the ball pocket of the hub boss ①, cutting off the transmitted torque. At this time, the action ring ③ moves in the axial direction (towards the adjustment ring ⑨), and this movement can be used to detect an overload with a limit switch, proximity switch, etc.

- When restarting the machine, after removing the cause of the overload, rotate the input or output side of the torque releaser. When the steel ball reaches the specified ball pocket position (one position per rotation), it will be automatically reset by the force of spring ④.

If you have any questions about specifications, please contact us.

The dimensions and specifications listed may be changed without notice for improvement purposes.